This post is also available in: Français (French) Italiano (Italian) Deutsch (German)

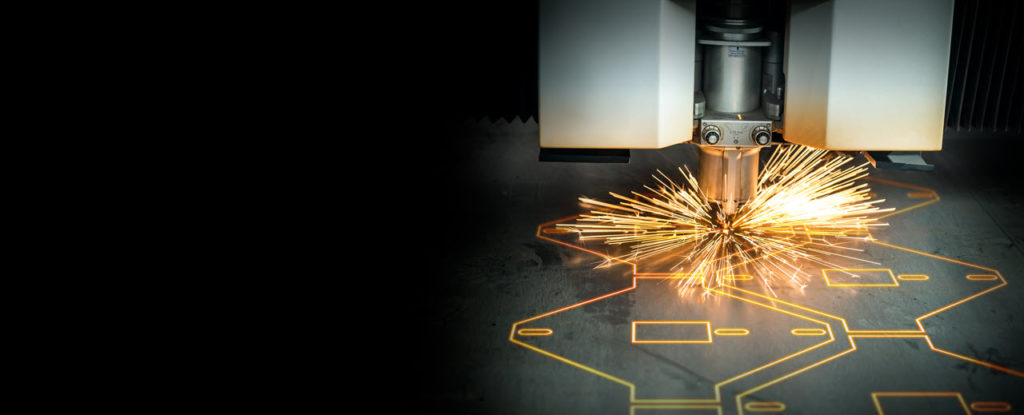

Create optimized and associative multi-sheet layouts for sheet metal and non-sheet metal with the Fusion 360 Nesting & Fabrication Extension.

The Autodesk Fusion 360 Nesting & Fabrication Extension unlocks advanced capabilities to create optimized and associative multi-sheet layouts in preparation for cutting on CNC machines. Whether you’re working with sheet metal or non-sheet metal components, the Fusion 360 Nesting & Fabrication Extension delivers the tools you need to minimize material usage and maximize your productivity. Here are three reasons you should start using the Fusion 360 Nesting & Fabrication Extension today.

Consistency with automation

Productivity is the key to making any process easy to learn and easy to use. The Fusion 360 Nesting & Fabrication Extension automatically detects the applied material and material thickness from the design. It then divides them across separate nests and applies material-specific defaults. These are stored within the Process Material Library, to ensure that each material is appropriately nested every time.

Component quantity is also automatically detected from the design. You’ll only have to define nesting properties once per component, rather than once per component instance. This streamlines the process and allows you to define nesting properties efficiently. You can also generate nesting reports and conduct cost comparisons on studies, nests, and individual sheets. All of which allows you to optimize material yield and minimize material usage.

Design and manufacturing associativity

Design changes are inevitable, whether it’s a slight change in the size of a component or a fundamental change to an overall design. The Nesting & Fabrication Extension makes changes easier by being completely associative to the design. Any changes are automatically consumed, and nests are regenerated to align with the new design. This is a huge timesaver, and really accentuates the power of integrated design and manufacturing.

The Fusion 360 Nesting & Fabrication Extension offers the ability to nest external designs to further minimize material usage. Having the ability to save nesting information with the original design, such as orientations, thickness overrides and choosing which components to ignore, means this only needs to be completed once. Every time you decide to nest that design in the future, these settings will carry over and associatively link to the settings in the original design.

In manufacturing, any changes to the nest properties —whether that be allowable rotations, quantities, or nesting material — are automatically consumed by pre-created nested sheets. Any changes to the material library are also automatically consumed. Thus, your nests are always up to date and ready for manufacturing.

Integrated nesting and fabrication

Efficient workflows and effective processes are at the forefront of Fusion 360. This is no different with the Nesting and Fabrication Extension. Having all your nesting functionality in the same workspace as your manufacturing setups and toolpath creation is vital. This minimizes human error and maximizes your productivity.

Integrating the nesting functionality within manufacturing allows you to automate the creation of manufacturing setups. Spend more time cutting parts and less time programming. Stock bodies, which are created while generating nested sheets, are then applied automatically while creating setups. This means you no longer have to manually input the size of your stock material repeatedly. Thus, saving you time that can be spent on cutting parts.

Once you have your setups, you can benefit from automatic contour selection and templates while creating your toolpaths. This further streamlines your processes and gets you to that all-important NC code. Not forgetting remnant cut sketches, which are automatically generated to ensure any excess stock material can be efficiently stored.

Get started with the Nesting and Fabrication Extension

Whether you’re looking to optimize your material usage, streamline your nesting, or bring consistency to your workflows, the Fusion 360 Nesting & Fabrication Extension is the right choice for your business. For an up-close and personal look at how to use the Nesting & Fabrication extension, explore these webinars:

Optimize material yield with automated nesting

Optimize material yield and reduce programming time with automated nesting

Get started for free today!