& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

2 min read

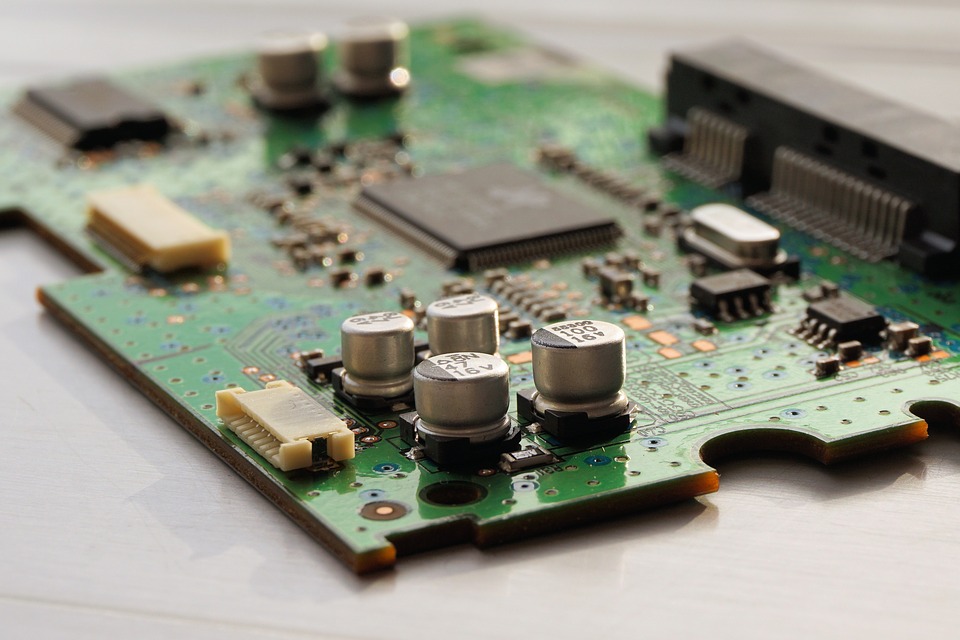

When examining the realms of additive manufacturing within the constraints of electronics, there are 2 distinct production methods. There are 2inkjet-stylele printing techniques used to produce circuit boards. Typically, this method involves a printhead that works on a flat horizontal surface, laying down some kind of conductive chemical or metal. This 2D ‘printing’ method allows for the fast production of custom circuit boards, which really isn’t possible given the way circuit boards are mass produced within the industry.

Straying from 2 dimensional additive, there is also the realm of 3D circuit board manufacturing. These methods utilize an extruder head that lays down beads of conductive metal. The advantage here is the ability to have free flowing wires interconnected within various 2 dimensional boards. The advantages that lie in 3D circuit board printing remain in constraints to size and workability. Having the ability to design 3D connections between compact boards is something that is virtually impossible given modern circuit board creation techniques. Through the combination of both 2D and 3D additive circuit board manufacturing, we are beginning to see a drastic change in how electrical systems designers build products.

The current state of the additive manufacturing industry lies mainly in mechanical part generation. Engineers are easily able to quickly prototype a mechanical component, but we are only beginning to see the emergence of electrical additive.

It’s important to clarify the few types of additive electronics manufacturing that are currently fighting to become the next main manufacturing technique. There are both filament based printers and conductive ink based printers, each in their respective 2D and 3D realms. Within inkjet 2D printing, usually the printhead released a viscous conductive ink or some methods involve the extrusion of 2 chemicals which then react to create a thin bead of silver. The 3D realm gets a little more complex in both extrusion and material methods. There are conductive gels, embedded copper conducting filament, graphene substrate printing, and even a conductive aerogel extrusion applicator. Each of these techniques could be researched in their own right, but let’s focus in on the additive electronics industry as a whole.

3D printed circuit boards are and will make an emergence in two areas. There is a niche place in large-scale manufacturing design for 3D printed boards. This is likely where advances in the electronic additive industries will stem. What will be much more highly praised in the circuit board realm is the ability for makers, DIYers, or even engineers to rapidly prototype a circuit board without dealing with the harsh chemicals that PCB manufacturing typically entails.

The combination of additive manufacturing and electronics is something to get excited about. It means that the day and age of being able to rapidly prototype and print not only mechanical but electronic parts is soon approaching. We are beginning to see fast production of virtually anything become an actuality, and that’s pretty cool.

Sources:Advanced Manufacturing, Optomec, Science Direct, Spi Lasers

This post was originally published on Short Sleeve and Tie Club. You can read the original here.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.