Before we get to the meat of this blog post, from everyone here at Autodesk, and the Fusion 360 team, we sincerely hope that in this troubling and uncertain time, that you and your loved ones are safe, well, and healthy. Our top priority right now is ensuring that our community is doing well and that they are safe, connected, and healthy.

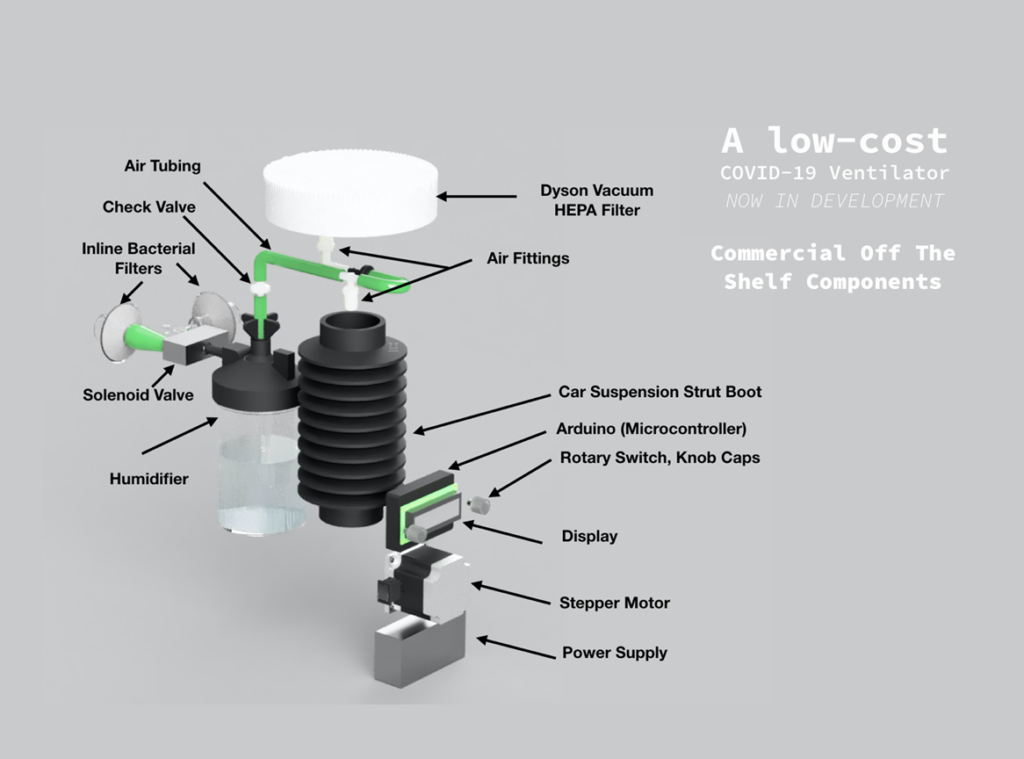

Innovators Build Low-Cost Ventilator, Design Assembles in Minutes, Uses 3D-Printed Parts

As you no doubt are aware (except you Jared Leto, you get a free pass), we’re all experiencing a global pandemic through Coronavirus (COVD-19), which is significantly impacting our lives in one way or another. One of the best things about working at Autodesk, and in the manufacturing group no less, is just the staggeringly positive and incredible response from makers, innovators, designers, machinists, and everyone throughout the industry, without question or query, rally to support in any way they can. No doubt you’ve seen that as we creep further and further into the reality of life under COVID-19, the strain to our medical systems globally, as well as demand for equipment that would minimize spread outside of hospitals, is rapidly increasing. Mercifully, all of you out there in the Fusion 360 community are supporting local and global efforts, and this is just one such incredible story.

Corey Mack, an RIT alum, most known for his work on disaster relief concept, and the entire team at the COVID-19 vent project responded to this global challenge rapidly and really intelligently. Realizing that ventilators are the most critical element for patients who have particularly acute cases of COVID-19, the team zeroed in on how to make an effective vent, easily, when the available materials are rare. The COVID-19 Ventilator is manufacturable in 1 hour, is made entirely from existing components available in the market. Remember Apollo 13, when they had to fix the rocket using only other parts of the rocket? The COVID-19 Vent is like that, except the rocket we have to pull pieces from, is the manufacturing industry in its entirety.

The best part about the COVID-19 Ventilator is not just that it’s using off the shelf parts and doesn’t require anything new to be manufactured, but most of the parts necessary to make the Ventilator are in abundance. Still not impressive enough? Well, it’s not just one piece of a ventilator assembly. It is a ventilator, which means there needs to be onboard control, which is covered by an Arduino, giving the ventilator CPAP, Pressure Control, Pressure Support, and Assisted Control modes. It’s all coming together, right? This isn’t just going to help with COVID-19, but with any disaster relief that requires assisted respiration!

COVID-19 Vent is building its first ten ventilators in Rochester, NY, with plans to test them in five medical centers the following week. The company is currently in talks for licensing in Switzerland and India and will seek FDA approval.

The COVID Vent was designed and collaborated with manufacture using Fusion 360. “We just saw the need, built it in Autodesk Fusion 360 in just four days, and the prototype will come in a week,” says Corey Mack, Founder at COVID-19 Vent. “Everything about this device is like fighting this virus. We are 100% full-force dedicated to design, adapt, and build these devices. By building the COVID-19 Vent in locales all over the country, we’re buying time to treat as many people as we can with the efficiency of local supply chains right in the same state.”

For more information on COVID-19 Vent, visit www.COVID19vent.com.