This article will cover why STL files are outdated and why 3MF files are the next generation file format for additive manufacturing

Designers and engineers using additive manufacturing are very familiar with STL files in their design process. However, the writing is on the wall: STL files have brought us a long way in the 3D printing space, but the next-generation additive manufacturing file format is here: 3MF. This article will cover why STL files are outdated and how 3MF files can make your life so much easier.

Why are STL files outdated?

Let’s start with some quick context and history. 3D Systems created STL files to translate design data into 3D printable data, using a mesh-based format for operation with slicing software. STL got its name from Stereolithography but has had a few acronyms post-creation applied to it. You may have heard the term ‘standard triangle language’ or ‘standard tessellation language’ used.

We’ve briefly talked about STLs before, but to reiterate the three core points:

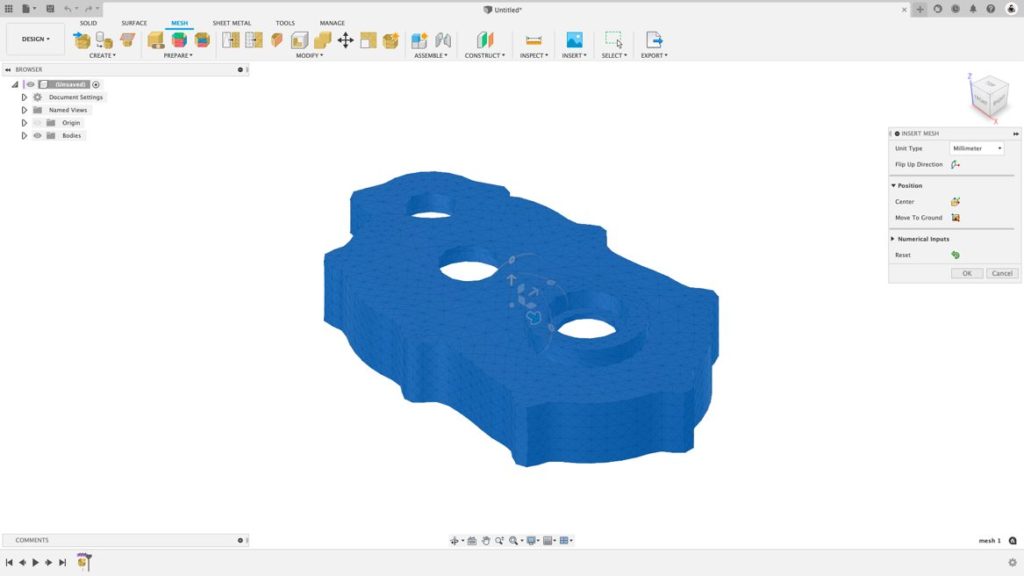

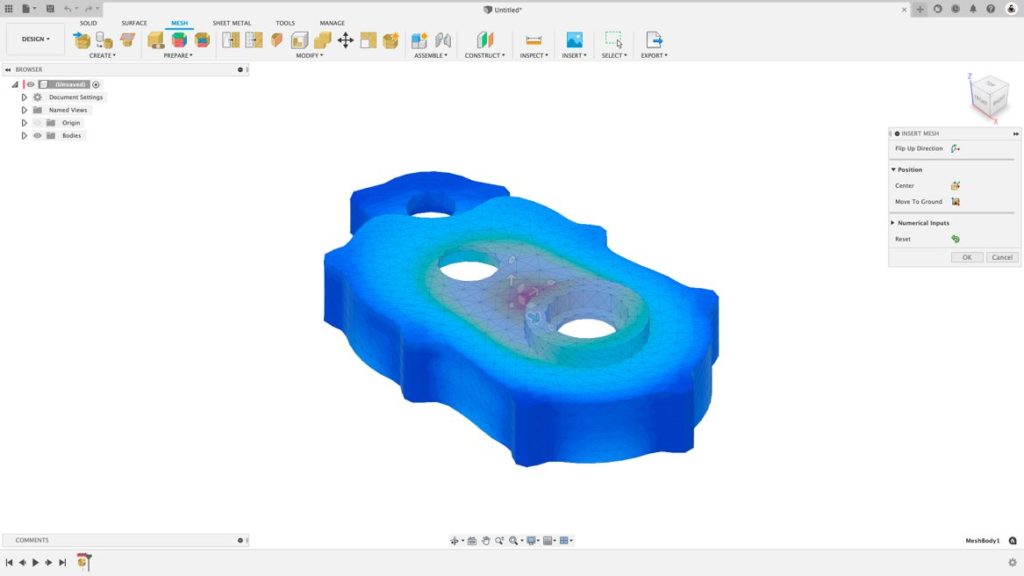

- Converting design data to STL format can be destructive. Just like any solid to mesh data conversion, the process cannot translate 1:1, which drops detail and creates fidelity discrepancies.

- STL files are gigantic, especially in comparison to solid models. This is unavoidable because of how mesh-based geometry architecture works.

- STL files can’t carry any actual manufacturing data. They’re a file format that carries mesh data. This is why so many slicers also support OBJs—there’s strictly no reason to limit a slicer to STL format only. The lack of any data beyond geometry is why printing with color can be more complicated than it needs to be with STLs.

Wouldn’t it be nice to save more than raw geometry for manufacturing? What if you could store support material, color, accurate scale (STL is unitless, so scale is often a challenge), and even print settings?

What is 3MF file format?

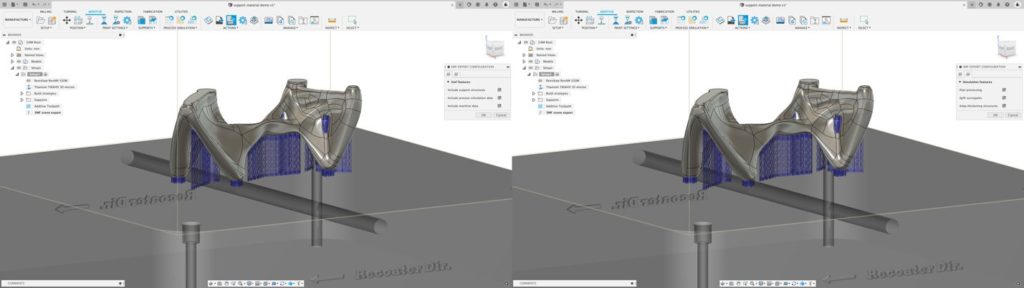

Welcome to 3MF, the next generation of additive manufacturing data management. If you’ve ever opened an STL file with multiple parts and tried to select them, you know the pain of them all being treated as one part. 3MF files are capable of managing multiple geometries and identifying them independently. This opens up a lot of possibilities all on its own. SLS printers enable you to share your packed build volume with anyone and make all the parts in your volume selectable. Your support material strategy is also shareable while still selectable, editable, and removable.

Additional 3MF benefits

3MF also carries color data. When using any color-capable 3D printer, you can bring your texture information over with the print. If you’ve ever tried to get color data from your design CAD over to a slicer, you know just how laborious this can really be! With 3MF, it’s as simple as exporting in the format, and the textures carry with the file!

The benefits to 3MF don’t stop there. 3MF file format is also “human-readable,” meaning you can open the file in a text editor and quickly understand what’s going on. You may wonder why this is relevant or necessary, but the machinists among you will get this immediately. Here’s a parallel example with machining: post-processed CNC data is easily readable. Data is very digestible, from lines of code that state coordinate information to data that shows when the machine needs to pause, switch a tool, etc.

Lastly, you can make 3MF files destructible. This feature means you can limit the number of part copies before production. This feature opens up many opportunities for additive manufacturing—it allows additively manufactured products to distribute similar to the physical good wholesale model.

Interested in trying out 3MF for yourself? Download a Free Trial of Fusion 360 here