Learn what 5-axis machining is and how Fusion 360 and the Fusion 360 Machining Extension can support your next project.

5-axis milling is, without a doubt, one of the more challenging forms of machining. Utilizing simultaneous 5-axis machining software can be extremely complex and expensive, but it doesn’t always have to be. Autodesk Fusion 360 is a comprehensive, integrated CAD/CAM tool that offers full 5-axis capabilities alongside 2-axis and 3-axis milling capabilities. The Fusion 360 Machining Extension unlocks even more Fusion 360 CAM functionality for those looking for more advanced features. In this brief overview, we’ll delve into what 5-axis machining is and how Fusion 360 supports the process.

What is 5-Axis Simultaneous Machining?

3+2-axis milling involves locking the cutting tool at a specific angle determined by the rotational axes (A and B) while using a 3-axis program. Often, this process requires the engineer to reposition the cutting tool between cuts. 5-axis machining, on the other hand, uses a mobile cutting tool that can travel across the X, Y, and Z axes while also rotating around the A and B axes.

The A, B, and C axes are labeled alphabetically in correlation to X, Y, and Z. Essentially, the A-axis is the rotation around the X-axis; the B-axis is the rotation around the Y-axis, and the C-axis is the rotation around the Z-axis. For examples of positional multi-axis applications, refer to this positional multi-axis video library.

Simultaneous 5-axis milling interpolates the tool tip and the tool vector between tool positions. The machinist can control machine angles and positions using the tool vector input.

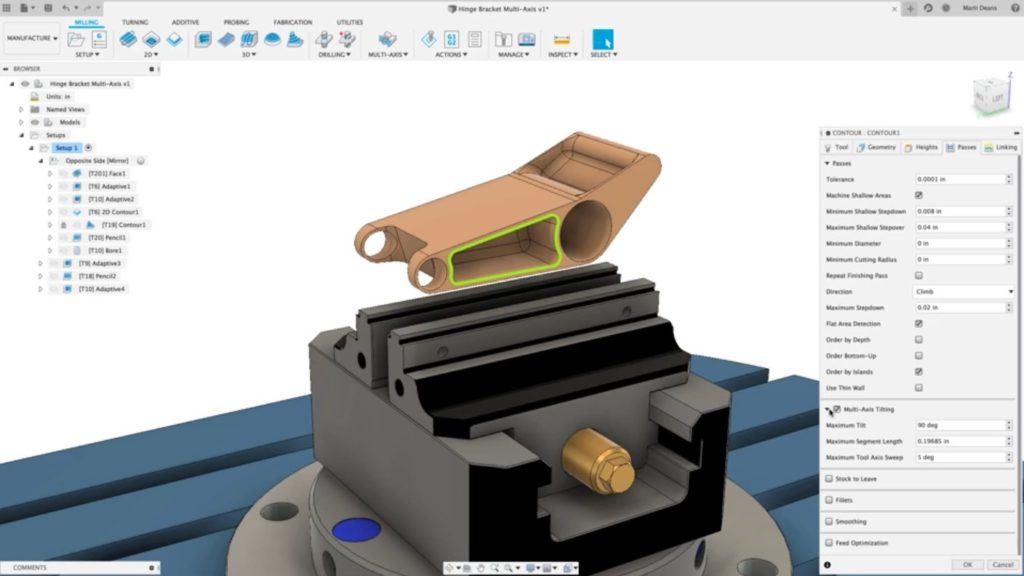

Fusion 360 offers a simple but powerful workflow to transform milling toolpaths in positional 5-axis machining. A machinist can set up and program multi-part fixtures to increase efficiency while also reaching features that would have taken another cutting tool adjustment on a 3-axis machine. Additionally, because the product remains within the machine setup for most features, the machinist can maintain a more accurate tolerance without a troublesome relocating process.

Fusion 360 Machining Extension

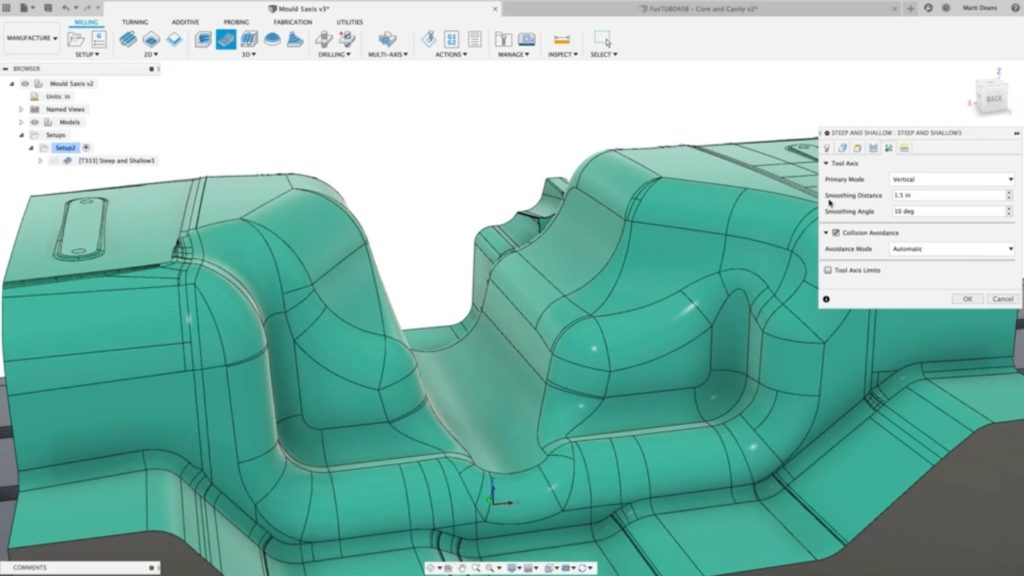

The Fusion 360 Machining Extension extends the Fusion 360 CAM capabilities even further, giving machinists access to advanced 3-axis and 5-axis strategies, toolpath optimization, and process automation. For example, the Machining Extension features automatic tilting capabilities. Fusion 360 automatically tilts the tool when it detects an interference, avoiding collisions with the tool or lathe. Machinists can also use lead, lag, and side tilting parameters to improve cut conditions where the tool meets the material, creating a high-quality surface finish and reducing tool wear.

Fusion 360 allows machinists to enhance simultaneous 5-axis projects without sacrificing time, productivity, or money. Try it out today!