Want to manage your company and production processes like never before? Great news: you don’t have to break the bank or sacrifice resources to get there. The secret to having it all lies with operational efficiency and implementing a system that works for you.

Running an efficient operation allows you to reduce costs and waste while still delivering high-quality products and services — all keys to running a successful, profitable business in today’s competitive landscape. Let’s take a look at five ways to improve operational efficiency.

Visualize your workflows

The human brain can process images up to 60,000 times faster than text. So why not implement technology that helps you visualize your manufacturing workflows? Visualizing your workflows allows the entire team to gain visibility into the production process. Quickly see how production is progressing and where bottlenecks are occurring. Ultimately, you’ll be able to set priorities and improve the production process.

Manage machines and maintenance schedules

Machines, machine automation, machine intelligence, machine learning — yep, you’ve heard it all. Machines and (our brains, of course) keep businesses running day in and day out. You can make machine management and maintenance easy with proper systems in place. Stay on top of how well the operation is running while:

- Knowing which machines are down and which ones need maintenance

- Scheduling maintenance to minimize downtime

- Manage production hurdles related to employee shortages, products, and machines

Know your inventory

Inventory — such an exciting topic, right? Well, the truth is, you can’t bake a cake without flour. When you need it, you need it. Inventory management is the backbone of planning, ordering, fulfillment, customer satisfaction, and revenue growth. By implementing inventory management, you’ll be able to track raw materials from batch to finished product and manage your warehouse inventory and organization. You can also track associated operations and raw materials consumed. In the end, this is a win-win for all. You save time and money, and your customers are happy with timely deliveries.

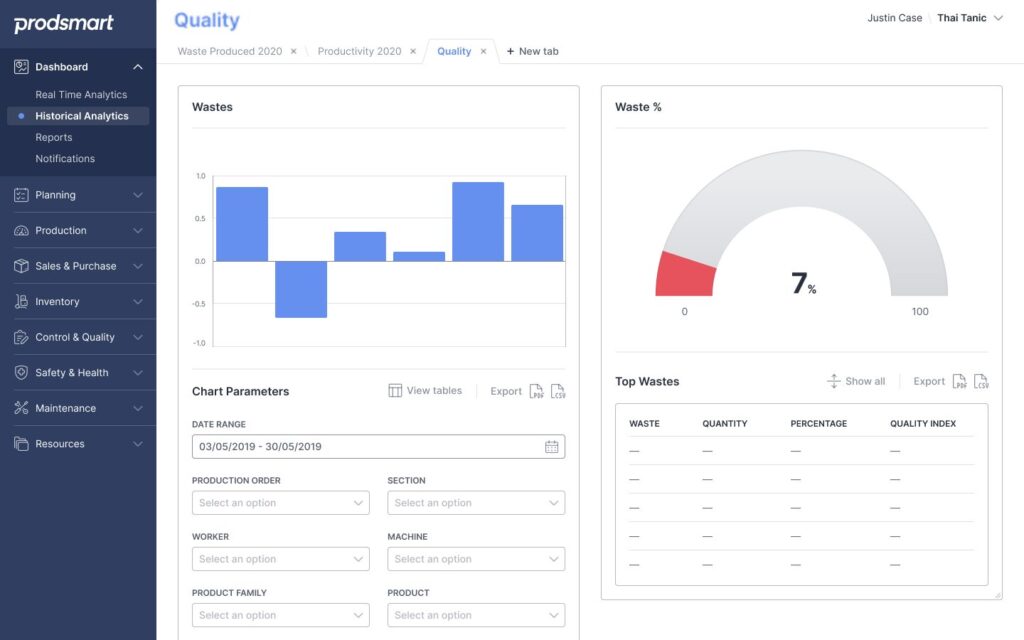

Implement quality tracking

There are only about 80 words in the English language that start with “Q.” That said, “Quality” is likely the most important term when it comes to creating superior products, exceeding customer satisfaction, and maintaining a business that will be here for the long term.

A quality management system allows you to maintain tracking and traceability all in one place. ISO 90001 and ISO TS 16949 tracking are easy, and you can generate reports on demand. Your entire team will even have access to the information they need, with the ability to check quality parameters, generate quality reports, and ultimately know exactly what they need to do. Simplification and any auditing process you go through are made easy.

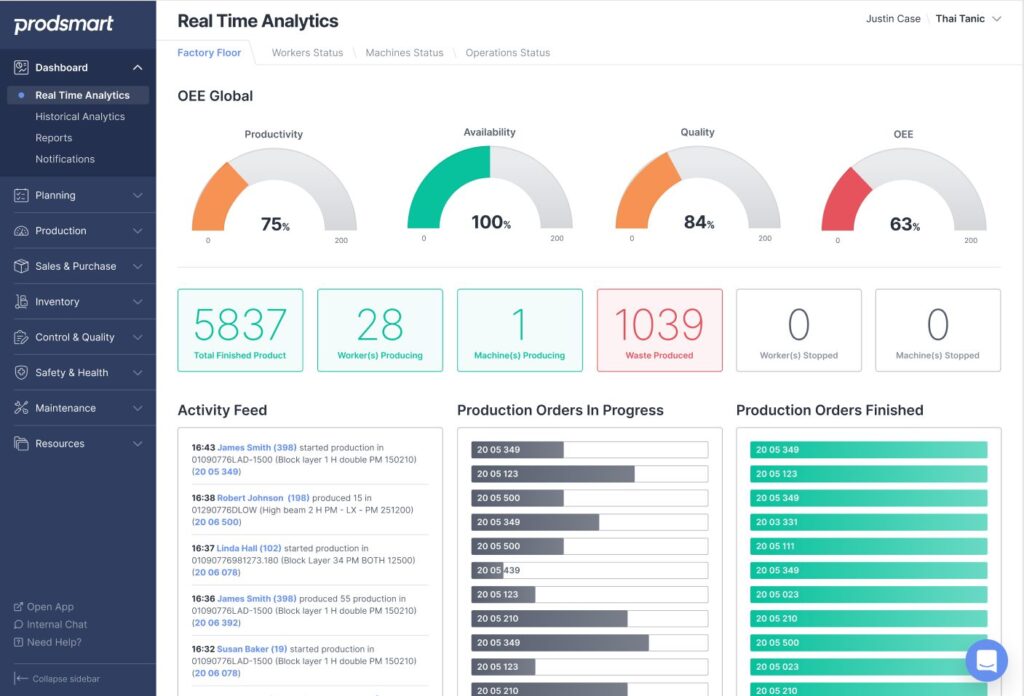

Track your data in real-time

This is a no-brainer, right? Who doesn’t want to track data in real-time? By implementing a manufacturing execution system (MES), you can track all aspects of your business. This includes orders, materials, maintenance, waste, time, cost, and more. You’ll even gain access to a real-time dashboard for connected manufacturing.

Your entire team has access to the information they need, from in-process probing in your CAM solution to Metrology reports. The ability to check tolerances, check surface qualities and send reports to quality assurance is the workflow you need to expand your business. Get access to data when needed, stay connected when you’re offsite, and respond quickly when issues arise to maintain a seamless, quality production process.

And there you have it. Five, rather simple (when you break it down), ways to improve operational efficiency. Something every business strives to do every day.

Looking for a solution?