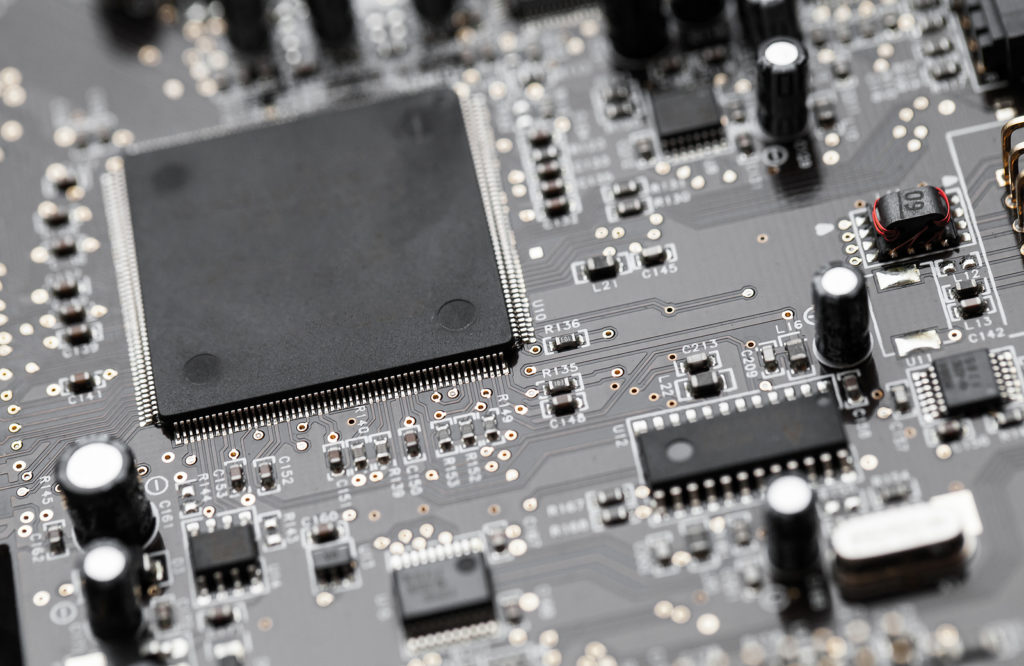

The Versatility of PCBs and PCB Design

Printed circuit boards (PCBs) are the driving force behind today’s electronics. Innovation continues to increase the production of PCBs to meet the demand for new and complex electronics. While many PCB examples and applications aim to solve critical worldly issues such as climate change, aerospace complexities, and food shortages, other PCB applications are designed purely for entertainment and socialization.

Printed Circuit Board Examples

Industrial designers continue to innovate PCB design to increase manufacturability, heat transfer tolerances, and overall reliability. Here are five PCB examples that might surprise you:

1. Gaming Consoles

The PlayStation 5 and Xbox Series X are great examples of PCB design. Both consoles have elaborately printed circuit boards that boast the latest specifications of gaming innovation. PCBs in gaming consoles and PCs require planning and precision to minimize size, tolerate high temperatures, and increase performance—although the PS5 is quite large compared to its predecessors.

As with any industry requirement, PCBs must be efficient and reliable. Mass production of consumer electronics is possible due to stringent testing and regulation. In November and December 2020, Sony sold 4.5 million PlayStation 5 consoles.

2. Smart Telescopes

The basic design of telescopes has been around since the late 16th Century and was pioneered by Galileo shortly afterward. With printed circuit boards and CAD software, engineers are now creating smart telescopes of smaller stature. Smart telescopes connect a live view of specific cosmic quadrants to the user’s phone through WiFi using dynamic sensors and GPS location.

3. 3D Food Printers

Additive manufacturing—or 3D printing—has improved drastically over the last few decades and is prevalent in most industries worldwide. The medical industry uses 3D printers to create anatomical models, dental molds, and other medical devices like prosthetics. In more recent years, 3D printing was introduced into the food industry.

In 2013, NASA contractors were allowed to experiment with building food from its base elements using a 3D printer. The printer would produce protein, starch, and fat with coordinated textures, nutrients, and flavor. 3D food printing is still in its earliest stages but could one day provide healthy and sustainable alternatives. Without printed circuit boards, complex experiments like 3D food printing would be unobtainable.

4. LiDAR

The National Oceanic and Atmospheric Administration (NOAA) defines LiDAR as a remote sensing method that uses a pulsed laser to measure variable distances. The laser bounces light off nearby objects and, once the light returns, the sensor can calculate distances in real-time. LiDAR has been used to map topography above and below the ocean. More recently, engineers are implementing LiDAR into the automotive industry for automatic braking and autonomous driving capabilities.

5. Wearable Medical Devices

PCBs can be designed to withstand heat, vibration, long-term use, etc., depending on their application, making them ideal for medical wearable applications. For instance, medical-oriented PCBs might require a smaller, high-density design built on a flexible multilayer base material to avoid damage during equipment usage. Medical PCBs are held to higher standards than average, rigid PCBs to assure repeatable and reliable functionality. PCB design elements like routing, soldering, power supply placement, and basic board layout are essential when designing schematics.

Fusion 360 for PCB Designers

Analog connectors and components are distant memories to current industrial designers. Low-cost electronic components will allow PCB manufacturers to design and innovate well into the future. Fusion 360 integrates ECAD and MCAD software for an inclusive prototyping experience. Check out Fusion 360 tutorials to begin designing PCBs today.