& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

20 min read

[toc]

6 Years and Growing Fast

As we reflect on the last 6 years and how far we’ve come, we can’t help but feel humble and so appreciative of the support you have given us. We haven’t made a roadmap post this year, so we’d like to change that and update you regarding what we’re working on and how we’re continuing to evolve Fusion 360 into the best it can be.

To be the best end-to-end product development platform, you’re data needs to be at the center of your design lifecycle. We’ve been working hard on improving our data management experience, as well as focusing on delivering key projects in these three major areas:

Core Functionality Manufacturing Generative Design

Here Are Projects We’re Working On

With August and September updates behind us, we continue to march forward and develop functionality focusing in the three majors areas of core functionality, manufacturing, and Generative Design. Below are highlights of some of the projects we’ve got brewing that we’re the most excited about. As always, working on new projects is fun, but we are also constantly fixing issues, squashing bugs, and making improvements to how Fusion 360 runs, behaves, and serves you day-to-day.

![]() Improved Insert of canvas image and decals

Improved Insert of canvas image and decals

Inserting decals and canvas images has been limited to selecting from your local drive, which felt very disconnected from the philosophy of storing everything that’s relevant to a project in a centralized location, accessible by your team regardless of where they are located. We’re working on improving this experience so that you can upload your image files to your project and pick the images you want to insert as decal or canvas, directly from your project. This way your images are stored along with your designs, and you and your team will have access to them wherever you are.

Got feedback about this particular project? Tell us about it.

![]() 3D Sketch Improvements

3D Sketch Improvements

Today if you wanted to create 3D sketches, you’d have to create them all on the same plane first and then use the Move manipulators to move them out of the plane and into 3D space. This can become tedious very quickly. We’re improving the creation of 3D sketches so that you can start a sketch, and immediately pick which plane you want the next sketch point to go on, and start sketching on that plane seamlessly, without needing to use the Move command every time. This will make life way easier.

![]() Edit in Place for Cross-reference Designs

Edit in Place for Cross-reference Designs

This is a big project we’ve been working on. Another major area of the assembly design workflow we’re enhancing is to give you the ability to edit your inserted assembly parts right within the assembly itself, instead of opening it up in a separate document tab. We’re calling this functionality “Edit-in-Place”.

We’ve been developing Edit-in-Place (EIP) for quite some time now, and we’re almost ready to let you try it. EIP will also enable you to edit external components directly in the context of the assembly where they will be used. You will also be able to pull that assembly context into the component so that they can continue to design around and reference the assembly right from the component.

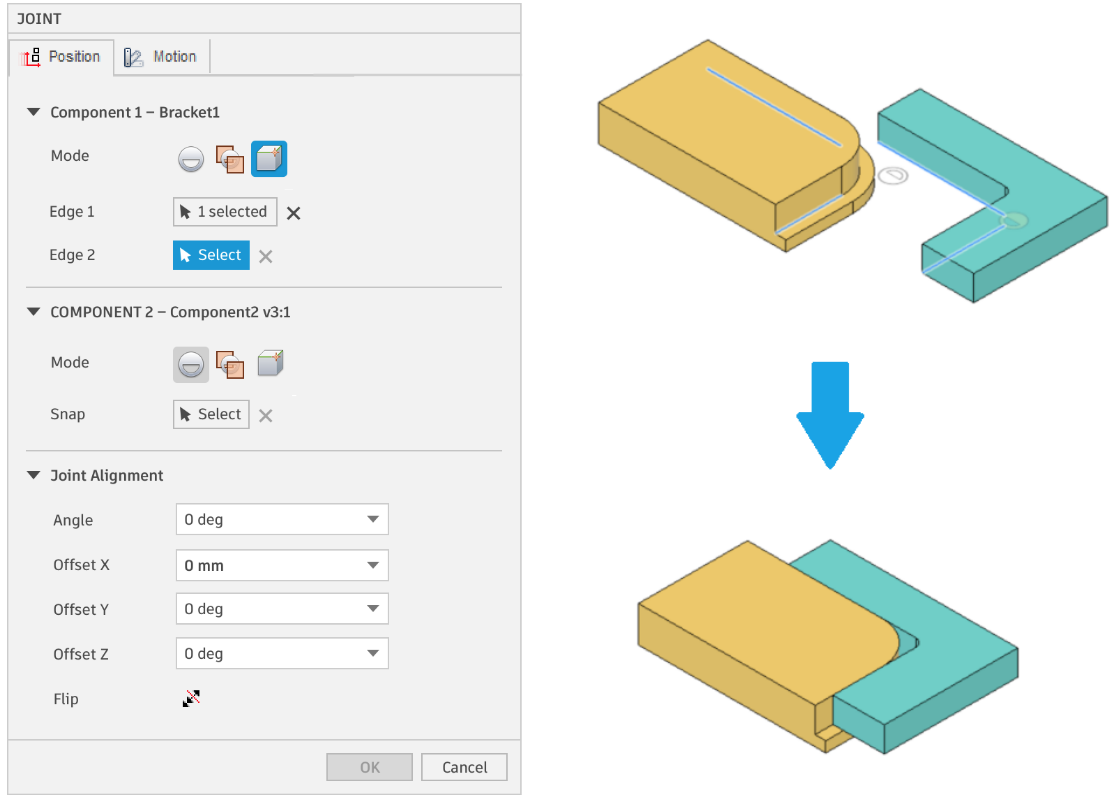

![]() Joints Usability Improvements

Joints Usability Improvements

Many of you know that one of the unique things about Fusion 360 is that it uses Joints to assemble components instead of traditional mates. One of the challenges we observed is the perception of position (mates) vs motion (Joints) when defining relationship between the 2 components.

Another challenge is the need for more Joint origin creation options and making it more discoverable. Currently, users may fail to find “Between two faces” Joint origin creation option in Joint command as it is hidden under RMB context menu.

To address these challenges, we are working on a new Joints dialog, and introducing a clear separation of position/motion options using tabs. We are also working on making “Between two faces” more discoverable by exposing it in Joint command dialog itself, as well as an additional option called “Between two Edges” to create a joint origin at the apparent intersection of 2 selected edges.

![]() Bend from Sketch Phase 2 Improvements

Bend from Sketch Phase 2 Improvements

Earlier in the year we introduced functionality to bend sheet metal parts based on the reference sketch. Now we’re working on expanding that functionality to support multiple bends. The experience will enable you to select multiple bend lines, set their bend angles, flip direction, position, and whether or not bend relief is needed.

![]() Convert to Sheet Metal from Direct Modeling

Convert to Sheet Metal from Direct Modeling

In the September update, we enabled you to convert designs with sheet metal-like thickness and characteristics into a Fusion 360 sheet metal body by using a single command. This however, is only available in the parametric modeling realm of Fusion 360, yet if you opened 3rd party designs, they come into the direct modeling side of Fusion 360 by default. This meant you had to know to turn the Timeline on in order to use the command.

Instead of doing the dance of importing/opening the design, switching over to history modeling mode, then going to the sheet metal tab to find the convert tool, we’re making it easier for you to convert those parts into sheet metal parts, by adding the sheet metal tab within the direct modeling directly.

![]() Mesh Workspace Out-Of-Preview

Mesh Workspace Out-Of-Preview

We rolled out the initial Mesh Tech Preview functionality with the July 27, 2016 update. However, the implementation was limited to Direct modeling (do not capture design history) mode. This meant that you could not roll back any changes or make edits once a mesh manipulation was completed.

The need to work with Mesh data is more relevant than ever. Whether you are working on reverse engineering with scan data or attempting to incorporate tessellated models from external sources to your design, you need reliable and performant mesh repair and manipulation tools.

This is exactly what we’ve been working on: making meshes a part of the Parametric modeling (capture design history) mode, providing you new automatic repair tools for the most common mesh defects, as well as introducing latticing capabilities to this workspace so that your designs can benefit from further light weighting for Additive Manufacturing, with a variety of lattice types including certain lattice types common in the medical field such as Trabecular.

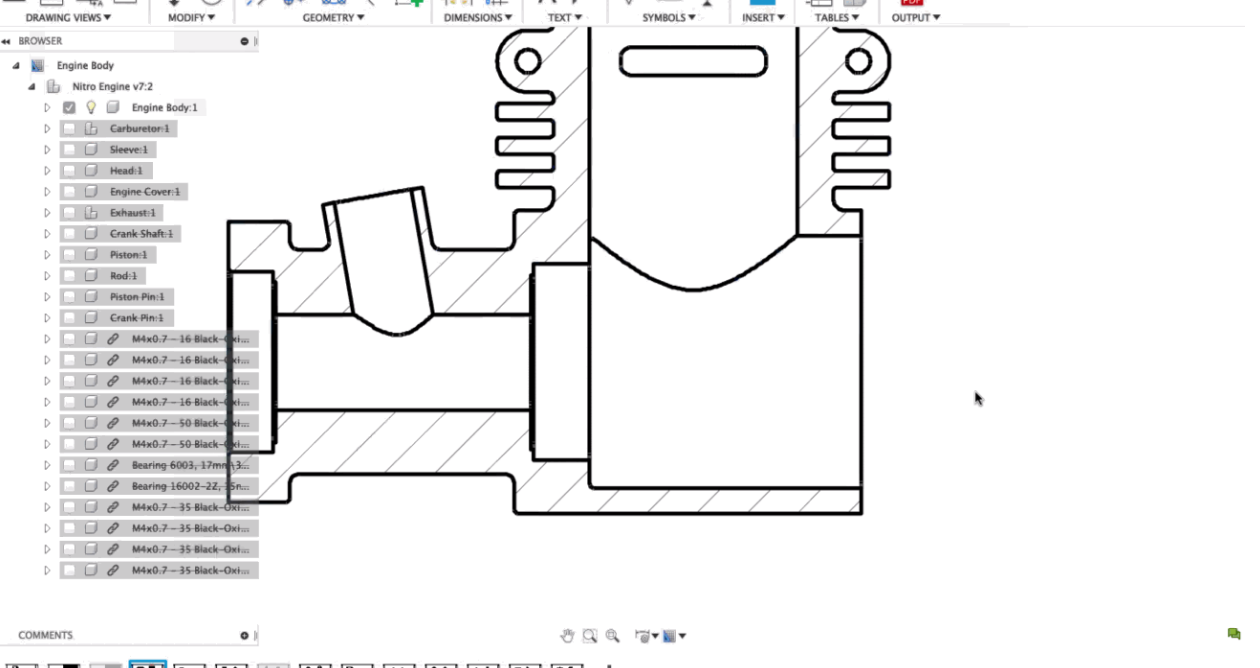

![]() Sketching Tools in 2D Drawings

Sketching Tools in 2D Drawings

The 2D Drawings workspace has come a long way, but we are well aware that it is still missing some pretty important pieces to make it fully mature (like broken views, weld symbols, break out views, just to name a few). These projects are no small feat, but we are significantly re-investing in resources to close these gaps and we remain committed to delivering continued functionality in Fusion 360 Drawings over the course of the year.

One of the most highly requested pieces of functionality that we’ve heard from the community is the ability to draw freely and directly on a sheet, and we’re happy to report that we’re making good progress on implementing sketching tools within the 2D drawings workspace. This opens up more workflows and flexibility so you can create custom symbols and callouts in your drawings, as you see fit. These tools will feel very familiar since they will behave similar to the regular sketch tools in the sketching environment.

![]() Basic Line-width Control

Basic Line-width Control

Another functionality in high-demand that we’re now working on is the first phase of providing you with basic control of your 2D drawing line-widths. This means you’ll be able to visualize line-widths on-screen. We’re also thinking of giving you the option to control line-widths across a drawing document based on ASME and ISO recommendations. We’ve got some ideas around how to do this, and have posted them in the Feedback Hub, and would love your eyes on it. If this project is relevant to you, tell us what you think!

[icon name=”lightbulb-o” class=”” unprefixed_class=””] Thoughts on Auto Dimensions?

It’s been a while since we’ve talked about automation of dimensions in drawings, but it’s still on our minds. When we floated the idea to the community back in April 2017, we got some encouraging feedback, and it’s time to circle back to get a deeper understanding from you all on this subject. W are partnering with Machine Learning experts to explore how we might serve up this kind of functionality in Fusion 360. Let us know what you think here.

We know 2D Drawings is a critical area for many of you, that’s why we have a dedicated roadmap for it with a deeper dive into the various areas. We’ve also kept it up-to-date. For more details on 2D Drawings specific project, check out the Mural.

![]() Extended Properties for Better Team Collaboration

Extended Properties for Better Team Collaboration

A major advantage of Fusion 360’s cloud capabilities is how easy it is to collaborate with your team members. We’re extending component properties so that when properties of a part is updated within Fusion 360, it is also updated on Fusion Team, (and vice versa) so that you can generate parts lists faster and more accurately.

The experience in Fusion Team also gets a major update with Navigation improvements, exposure of local components (with properties!) and enhanced history experience that makes it easy to track model vs properties changes.

Our Manufacturing roadmap also centers around 3 key themes: refining the details, expanding the capabilities and connecting the shop floor.

Refining the details

As we think about refining the details you have seen recent updates like the improvements to turning, addition of section views in the manufacturing workspace and accessibility shading. Upcoming additions include small things to linking model parameters in the Manufacturing space and larger things like tool library work highlighted below.

Expanding the capabilities

Expanding the capabilities has seen us leverage our portfolio of Manufacturing solutions to deliver things like Steep & Shallow and Drilling Automation. Below you will see some of the near term enhancements including toolpath editing, nesting, 4 axis capabilities, and additive manufacturing..

Connecting the shop floor

Finally, Fusion 360 is a connected product. We have made great strides in connecting the design and modeling process to the toolpathing processes, however, much of the data we create gets thrown over the fence to the shop floor. Examples of work that connect the shop floor range from better shop floor documentation to more advanced workflows that capture measurement information and bring that back into the software.

Let’s dive into some of the details below.

![]() Improved Tool Library

Improved Tool Library

We hear that you’ve been waiting on this for a while, and we’re happy to tell you we’re close to releasing an improved tool library. Multiple feeds and speeds? Check. Better turning tool definitions? Check. Improved search functionality and formulas enabled in definition fields? Check. And more improvements to come!

![]() In Process Stock Management

In Process Stock Management

There have been several very popular IdeaStation posts asking for the ability to carry stock between setups. We’re happy to tell you that this is a big area of focus for us right now. Continue rest machining for milling is close to being ready for customer testing in preview, and we’re building out the functionality needed to accurately simulate and visualize the rest stock. This is a big project and we know it is crucial to get it right in order to support your multi-set up workflows, so keep an eye out for updates to come and join the conversation on the Feedback Hub.

![]() Multiple Features for Probe Geometry

Multiple Features for Probe Geometry

We’re working on an improvement for the Probe Geometry feature that is accessible through the Manufacturing Extension. Soon you’ll be able to select multiple features for ‘Probe Geometry’ that will make it faster and easier to create more complex inspection sequences.

![]() Toolpath Trimming Coming to the Manufacturing Extension

Toolpath Trimming Coming to the Manufacturing Extension

The toolpath strategies available in Fusion 360 are pretty smart, but sometimes you need extra control for more complex machining applications. We’re working to bring toolpath trimming capabilities to the Manufacturing Extension for those of you who want to ‘tidy up’ certain toolpaths, remove inefficiencies such as aircutting, or avoid limitations in your chosen toolpath.

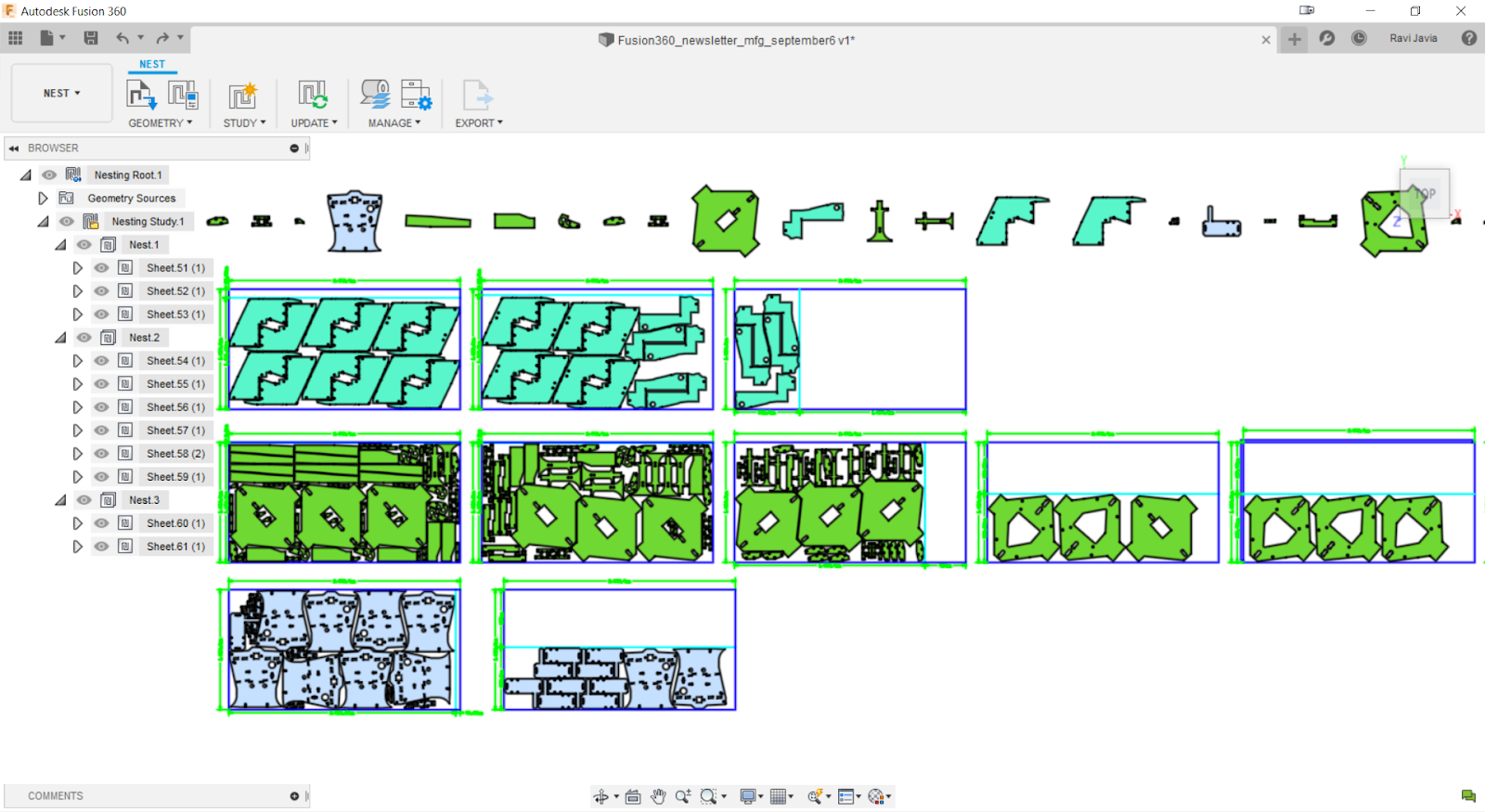

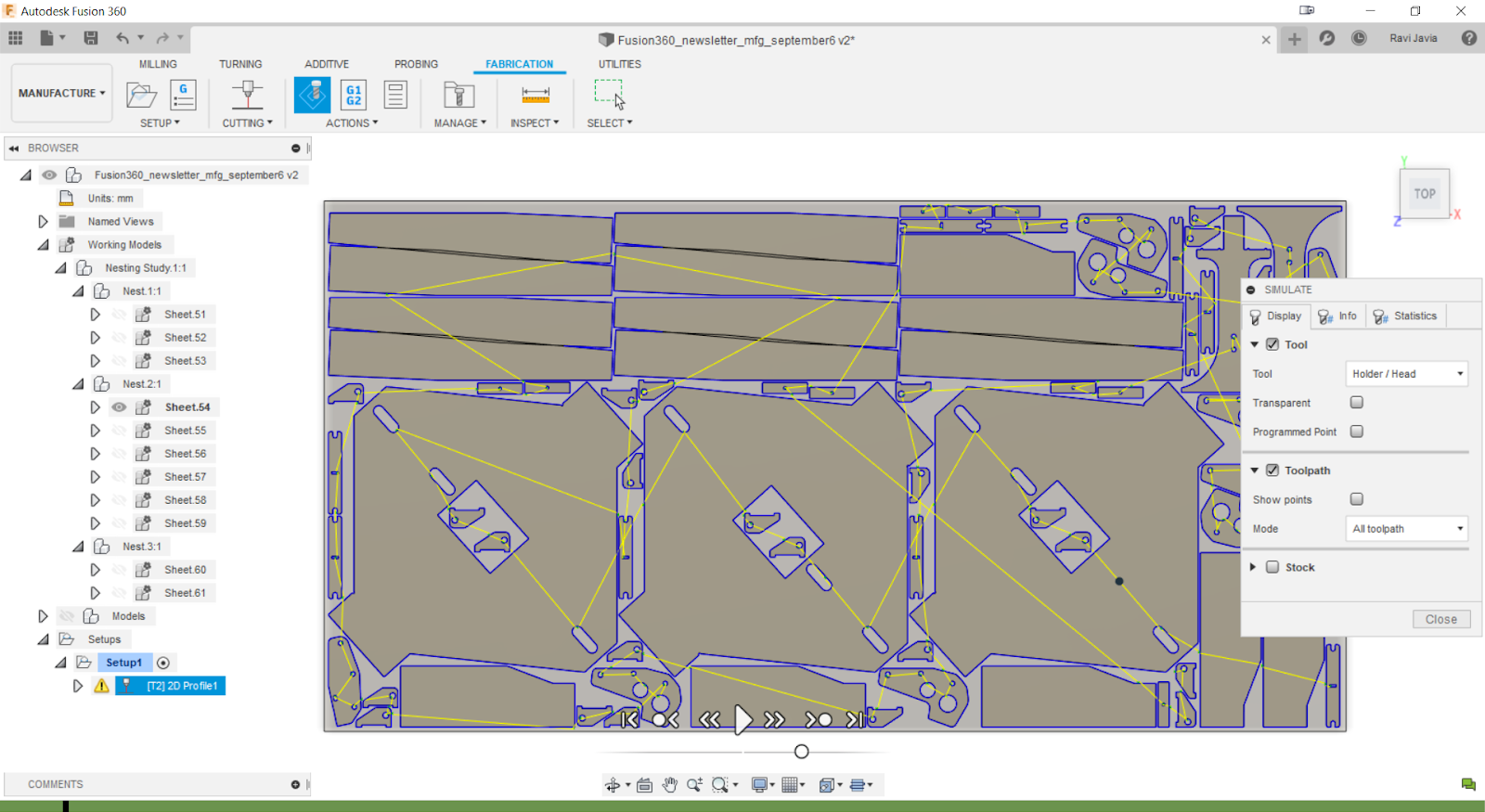

![]() Nesting Planned for the Manufacturing Extension

Nesting Planned for the Manufacturing Extension

As one of the highest requested features, we previewed it to those of you who attended our Fusion Academy. We’re now getting closer to enabling sheet metal nesting in Fusion 360. Right from the beginning, you will be able to go from sheet metal Design & flat patterning to Nesting to CAM as a complete end-to-end workflow. If you make any design edits, the related nests will become “out-of-sync” and can be updated associatively. These changes can also be propagated to CAM to ensure toolpath operations are up-to-date with design and nest updates. Alternatively, there will also be an option to export nest results as DXF. Moreover, the new “Convert to Sheet Metal” feature in Design will allow you to import non-native sheet metal designs into Fusion and make them nest-able. And this is just the beginning; nesting for non-sheet metal solids is already in the pipeline and will be available shortly after.

![]() More Turning Improvements

More Turning Improvements

You saw some major Turning improvements drop with the September release — this is just a taste of what we have planned for that space. Up next, we plan to give Grooving the same kind of attention to detail revamp we did for Profiling. Stay tuned!

![]() Adding 4 Axis Rotary Toolpath to the Manufacturing Extension

Adding 4 Axis Rotary Toolpath to the Manufacturing Extension

Many of you have a 4th, rotary axis on your machine tools, but don’t yet have a good way of finish machining non-cylindrical parts with it.

We’ve been hard at work bringing a 4 Axis Rotary toolpath to Fusion 360, and we’re happy to say that you’ll be getting to try it soon on those organic geometries — we’re excited to see what you make first!

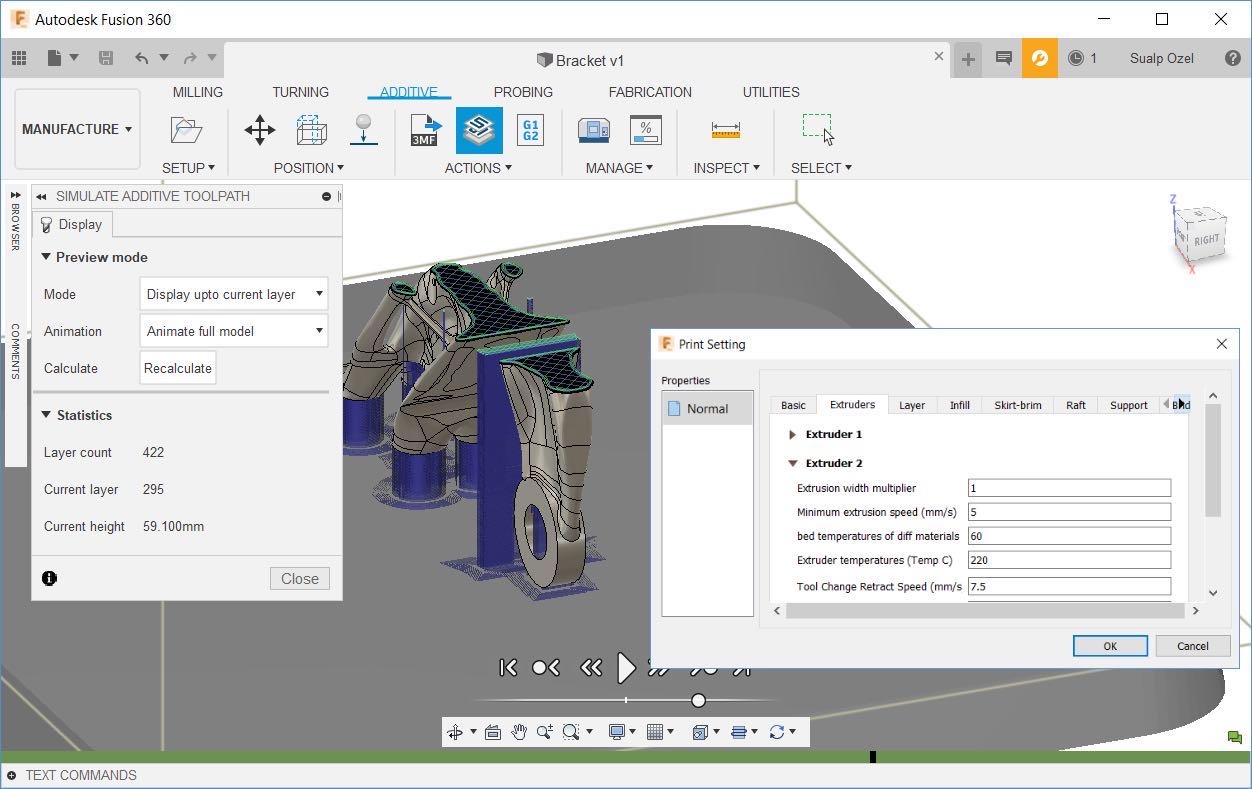

![]() Additive Manufacturing

Additive Manufacturing

Additive Manufacturing (AM) offer companies fabrication method capable of disrupting the status quo while providing them a means of market differentiation. Fusion 360 already offers several capabilities for Design with AM considerations, such as Generative Design and Shape Optimization. Once the Mesh project (highlighted above) is released, the latticed models can only be manufactured using AM.

With the Manufacturing Extension, one can produce these unique designs using Metal AM for production. However, in functional prototyping, as well as soft jaw / fixture creation, plastics are more common. To address this need for a connected design to make AM solution, we have been working on adding new AM technologies into Fusion 360, starting with Fused Filament Fabrication (FFF). This new method of sliding and toolpath creation will be available for both Single and Dual nozzle printers within the Manufacture workspace. Autodesk is an innovator in non-planar 3D printing and for generating high quality top surfaces, and we plan on adding this functionality into Fusion 360 in the near future as well.

![]() Improvements to Setup Sheets

Improvements to Setup Sheets

You will soon be able to publish, access, and comment on setup sheets on Fusion Team. We’re also planning on adding parametric views of operations and setups in setup sheets, such that the stored images will update should you go back and edit the associated strategy/setup.

![]() Live Machine Connection for Inspection

Live Machine Connection for Inspection

Also in progress is a live machine connection for inspection will allow you to evaluate measurement results in real time – so you won’t aren’t stuck waiting until the end of the sequence- this will enable more automated workflows in the future!

We are working to enable manufacturers to deliver on their solutions from Design to Make. Part of this challenge is to implement the right solution. The ultimate goal for any engineering activity is to strike the right balance between performance and cost to produce for a given design challenge or market opportunity. Engineers are constrained by time and energy they can spend on any design problem to fully explore the options that encompass the design space. That’s why we continue to encourage you to take advantage of generative design to help explore the design space, create options to solve engineering problems, and gain confidence in the design direction that is chosen to solve the problem at hand.

Since the release of generative design in Fusion 360 we have been gathering your feedback and developing additional capabilities to meet your needs. Some exciting capabilities are in the works and coming soon to Generative Design, enabling you to make better decisions and explore new ways to solve problems.

![]() Outcome Cost Estimation (Coming Soon)

Outcome Cost Estimation (Coming Soon)

We announced an exciting partnership with aPriori during AU London earlier this year to provide cost insights for generative design outcomes. We have been working diligently with the aPriori team and are excited to have integrated their technology with Fusion’s generative design capabilities and are ready to provide a preview of this integration with the upcoming product update. With only the addition of anticipated annual production volume as an input, users will now get insights to the anticipated part cost when using generative design, allowing for more thoughtful trade off analysis when evaluating cost and performance.

if this technology is important to you, we’d love to hear your feedback on it and how you plan to use it. Your feedback will directly impact how we continue to improve this experience. Head over to the Feedback Hub post to let us know what you think.

![]() Commercialization of 2 Axis Cutting (Coming Soon)

Commercialization of 2 Axis Cutting (Coming Soon)

The 2-axis cutting constraint has been in preview for a good while now. We have been making solver improvements along the way, focusing on improving how it creates internal holes in the outcomes. We will also be putting a few finishing touches on the associated pre-checks to help you ensure your setup will produce the best possible outcomes. Once completed, 2-axis cutting will be coming out of preview, and will be ready and waiting to help bring generative design to your water, laser and plasma production strategies.

![]() Commercialization of 2.5 Axis Milling with Tool Accessibility (Coming Soon)

Commercialization of 2.5 Axis Milling with Tool Accessibility (Coming Soon)

The release of the 2.5 axis milling constraint preview back in August was a major milestone, and we have since been working to refine this solution even further. Over the past few months, the teams have been actively working on improving the solution for manufacturability. Most notably, our teams have been developing support for tool accessibility, allowing the user to define a minimum tool diameter. Tool accessibility, improved pocket generation and better layer alignment are improvements that will be helping us bring 2.5 axis milling constraints out of preview and make our generative outcomes even more manufacturing ready.

![]() Visual Similarity Filter for Outcomes

Visual Similarity Filter for Outcomes

Often when discussing generative design with our users, the topic of visual appearance comes up as something they need to pay attention to as part of their design process. We have started our efforts to help users manage these interests by creating a Visual Similarity filter in Explore to help organize outcomes. Powered by machine learning, this new filter will identify and group outcomes with similar visual characteristics to make it easier to find the ones you like and quickly rule out the ones you don’t. Because we are using machine learning, the Visual Similarity filter will always be adapting to what it is observing. As you start to expand your design space through additional studies with new or refined setups, the filter will continue to update groupings based on your outcomes, making it easier and more efficient to find that perfect design.

![]() Explore in Fusion Team

Explore in Fusion Team

A key aspect of the value of generative design in Fusion 360 is the ability to share and collaborate with others when making decisions. With the inclusion of cost insights for generative outcomes, it is even more important for the broader organization, stakeholders, and decision makers to be able to access this data for discussion and selection. To that end, we plan to make generative results available through Fusion Team, allowing anyone with a browser to be able to view, sort, filter, and comment on generative outcomes.

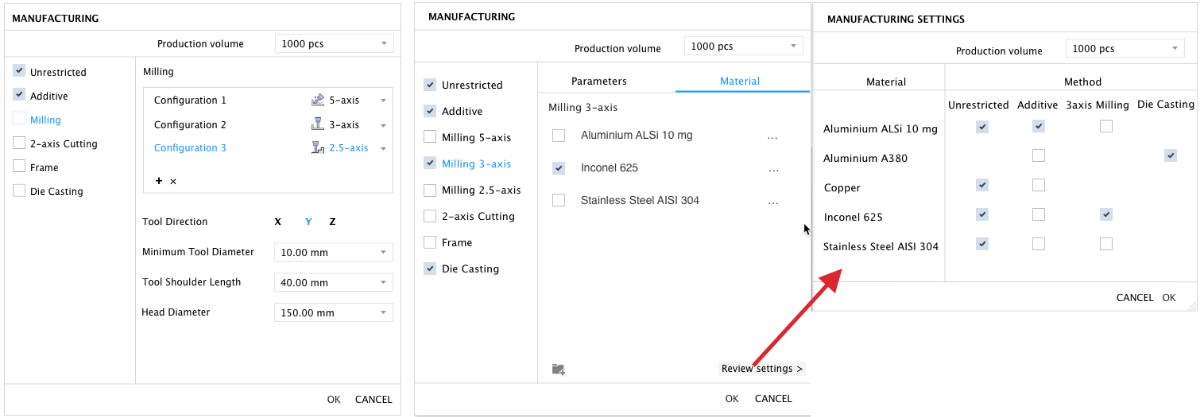

![]() Manufacturing Dialog Overhaul

Manufacturing Dialog Overhaul

With all of our work to add manufacturing methods over the past few months, the manufacturing dialog has become a bit too much, both visually and, for some monitors, simply too large to get to the OK button. We will be making improvements in a couple of phases, starting with refining the layout, and then adding the ability to control the materials used for each process.

[icon name=”star” class=”” unprefixed_class=””] You’re the best community ever

Now that Fusion 360 is six years old, and although there’s a wide array of improvements and additional capability in its future, it is becoming a more mature product. In this time, the IdeaStation has been a valuable source of feedback, brilliant new ideas, and improvements to existing workflows. It has played a crucial role in shaping Fusion 360’s roadmap and has helped us balance our priorities. Your input has been a critical part of the development process.

The IdeaStation now has an incredible amount of customer input, with over 8,000 ideas. However, due to the sheer volume of ideas, there are often great nuggets of feedback that get lost, and are frequently repeated in multiple posts by different users. Even for the idea’s we’ve accepted, it’s become difficult to draw attention from the community to influence our active development projects. This, combined with the product’s maturity and our clarity of vision for its future, mean that we need a new way to gather feedback more constructively and efficiently, for you and for us.

Today we’re announcing the new Feedback Hub. This will be a new forum, with an experience similar to the IdeaStation, but with a few key differences. Autodesk staff will be soliciting your input on specific features, improvements, experience, bug priorities, conducting studies / surveys, and previews, to name a few. Autodesk Product Managers, User Experience designers, and Researchers will have posting privileges on this new forum, and everyone will have commenting privileges.

We believe this new approach will make for more productive conversations about the product, will ensure direct contact between you and the Autodesk staff responsible for specific aspects of the product, and will ultimately make for more meaningful user input in shaping the future of Fusion 360.Given this new approach to gathering user input, we plan to archive the existing IdeaStation early next year. Product Managers and other staff will be replying to the top rated ideas as we launch the Feedback Hub, but it’s our belief that at this time, the IdeaStation model has served its purpose. The archive of the IdeaStation will be something the Autodesk team will continue to reference as we move forward, but voting and commenting will be disabled.

Thanks for all the great ideas, and please help us continue to make Fusion 360 better by providing input to our active projects in the Feedback Hub.

[icon name=”info-circle” class=”” unprefixed_class=””] NOTE:

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.