Welcome back to another Blog post! Today, we have a specific target. Are you a Designer? Yes? Then you are the target.

Since starting to use Fusion a few years back, I have become fascinated with the Simulation tools. As an Industrial Designer that has designed way too many things for mass production, I have had to adopt some Engineering mindset. Come with me on quick introduction to Static stress, improve your engineering and learn about how to be a better friend with the engineers on your team.

So, I am starting with a simple Shelf bracket. A basic “L” shape, keeping it as direct as possible. Fully dimensioned, as you can see (and saved).

My goal here is to test this “design” systematically for strength and to use as little material as possible. With that in mind, how about we select a Physical Material first? Right Click on the body, select Physical Material.

I am going to choose the basic Aluminum for now. Drag and drop the material onto the body (just like rendering materials).

Make sure your file is saved, and head over the Simulation Tab. You will be greeted with pop up window asking you to select one of eight Simulation tests. For this test, we are going to be running a static stress test. The Shape optimization test is a great compliment to Static stress and both will help you understand Generative set up more (foreshadowing on the next tech tip from me).

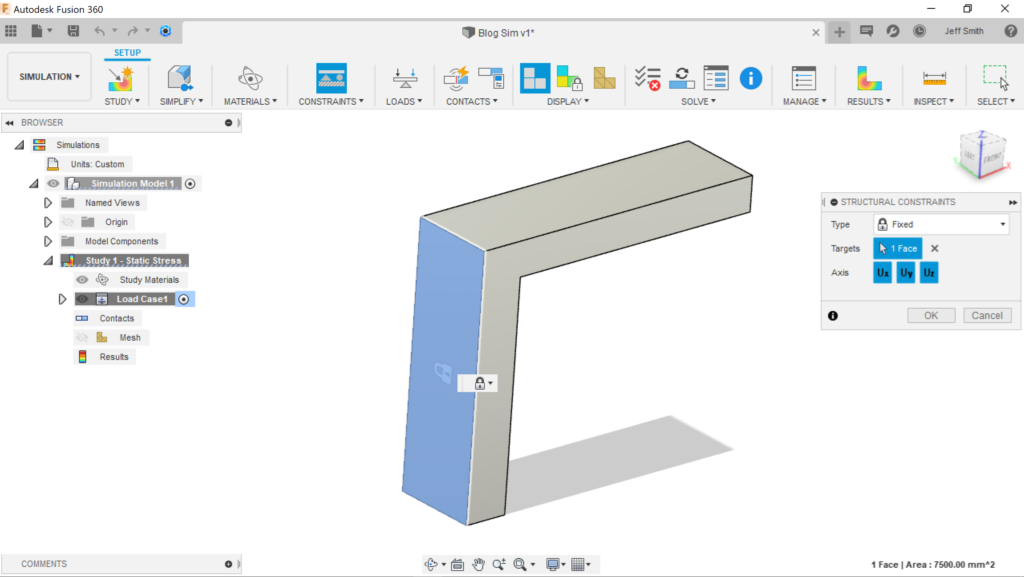

Just like CAM, work left to right. We already have a study started. We do not need to simplify, and technically we do not need to select a material (we did, but you can always select here as well). So, that lands us on constraints. Step one is to tell the computer what is locked on the body. These are called Constraints, and we will use a structural constraint here. In an effort to keep is simple, we will lock the back face of the bracket to the “wall”. There are many other ways (for example, if you had a bolt hole).

You can see here that I selected the back face in the structural constrains window. The X, Y and Z Axis are default locked (you can unselected as need for more complicated tests). I have the type set at fixed.

Next we will add a structural load to the bracket. This is in Load drop down list.

In the structural load tool, I selected the top surface of my bracket. Changed the units to lbforce (I think in mm for distance, but cannot do weight yet) and made the load 100.

Again, moving from left to right, I selected pre check from the solve drop down. Fusion checked, and I have enough information to in my set up to run the test.

As I am now ready to run my test, I select solve from the Solve Drop down. As you can see, I can run this locally or on the cloud. I will choose cloud for this one.

The test finished in moments, and as you might have expected I am way over engineered here. The minimum Safety Factor is 15. With that in mind, a safety factor of 3 is a good average for consumer products.

As a Designer, I can take this information and apply it to my design. To make this example efficient, I will simply reduce thickness. I think I made the bracket 25mm and 20mm thick. How about I adjust the model to 10mm and 7.5mm thick? I updated the model sketch, and came back to the Simulation tab. As you can see, all are linked parametrically. Fusion is telling me the results are now out of date. This makes complete sense as I just removed a ton of material from the model.

All I have to do is right click on Study 1 in the browser and choose solve. This time, I will run this test locally.

As you can see, after re running the test, I now have a safety factor of 4.5. Much closer to what I need and not over using material. Think about that. As a Designer, I just saved material and know that my design is structurally sound. That equals saving cost, time and effort. Could I reduce more and retest? You bet, and I hope you see the power you now have.

Is engineering important? Yes. Now, when you go to engineering team mates, you are so much farther ahead. If you really want to extend and olive branch to your Engineer buddies, export a results report here.

Pass on the PDF report to the Engineers. It will be Greek to you, but clear as day to them. Imagine their surprise when you show up with a part that is 90% ready and have a report to back it up? It will make them more efficient and they will WANT to work with you!

As always, I hope you enjoyed this tech tip. More to come. Do not be afraid of Simulation, just start simple with one body. It does get more complicated with more bodies and components. If you want to learn more about me, head over to my Instagram. https://www.instagram.com/blaster701/