& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

There has been a new addition to the way we calculate the depth of cut in Profile Roughing. What does it do? Why is it important? And How does it differ from the standard strategy?

Let us take a look at what we are doing today and let us refer to it as “Constant Depth of Cut,” because that is what we are telling the software to perform for us.

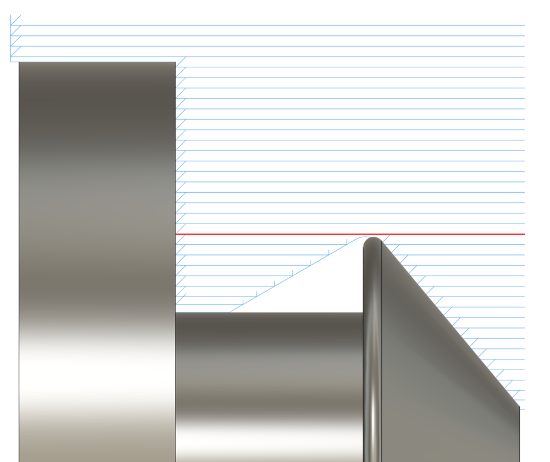

If we were to set our Maximum Depth of Cut to 2mm, it would apply that 2mm cut from the Stock Boundary downward ignoring the actual model geometry but giving you the expected results of having a predictable stepdown for each pass of the turning insert until we reach the bottom boundary (Revolved Center of Part).

A Maximum Depth of Cut here produces 2mm passes regardless of the part geometry.

Viewing the toolpath moves shows each pass at 2mm.

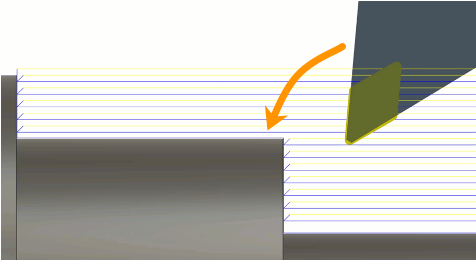

That tiny pass highlighted here is the main culprit.

‘Constant Depth of Cut’ on multiple shoulders

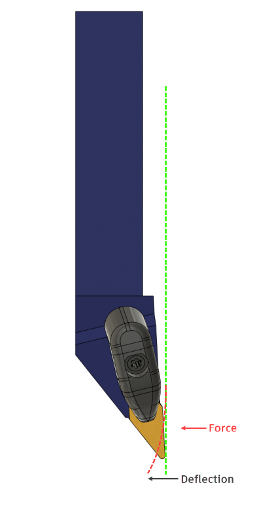

What’s the problem with that little pass, you might ask? It is simply not an equal depth of cut. But, that small change forecasts a lot of problems for us to determine later how we can make corrections to getting the right tolerance and surface finish. Even depths of cut mean we have even chip thickness, predictable deflection of the part or tool, and equal heat dissipation during cuts.

Keeping the variables to a minimum is always the ideal scenario. Minimizing variables ensures quick diagnosing of problems that might occur. For instance, if we have major tool deflection while cutting the same amount across multiple shoulders, we can simply adjust our tool offsets in the controller to account for the deflection for each diameter. If we have a constant depth of cut, which results in a thin final rough pass on one shoulder, but the other two are equal, we might have fluctuations in the resulting diameter simply based on the tool deflection. Now to fix an issue where we have variability, we need to go back to Fusion to change the dimensions of the single diameter to bring it into tolerance without disturbing the other two diameters.

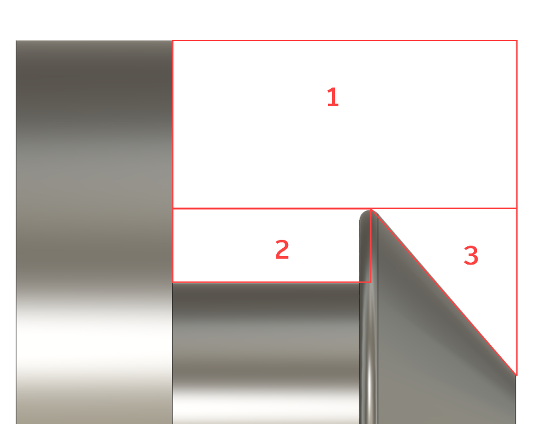

With parts that contain multiple shoulders like the example, we’re looking at, the ideal way to machine the depth of cut may not always be a constant prescribed number. The user can’t possibly be held accountable to measure each shoulder diameter and calculate an average depth of cut from the top of stock across the entire part.

Even Depths of Cut is here to save the day!

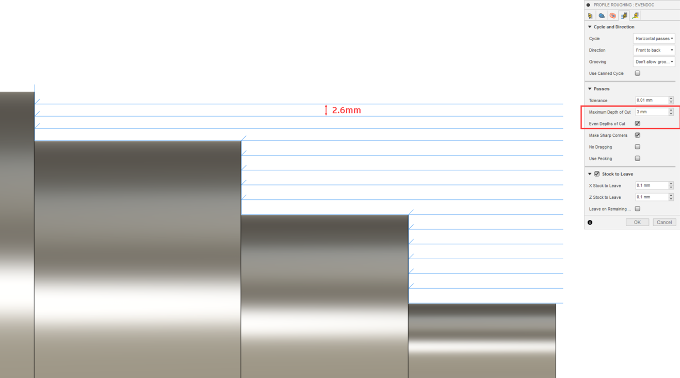

A “Maximum Depth of Cut” set to 3mm with “Even Depths of Cut” turned on, generated a 2.6mm depth to produce a more predictable result.

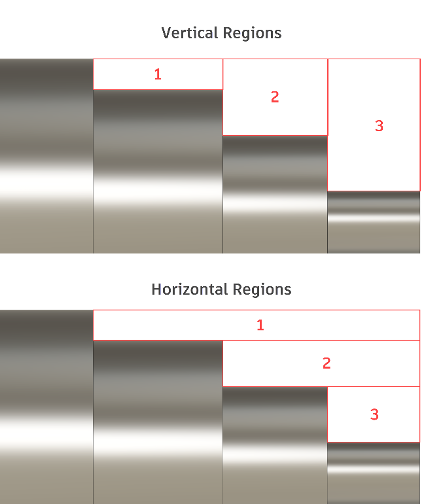

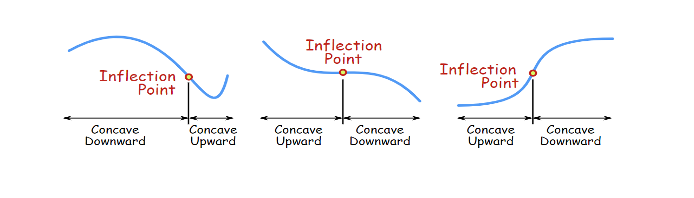

We split up each diameter into a ‘region’ to calculate the proper step-down of each Region and then merge them into an average that will evenly distribute for all widths. Below is two basic examples of how regions are defined in the algorithm based on whether the user chooses to do Vertical or Horizontal passes. For this instance we gave the software a suggested “Max Depth of Cut” of 3mm. 3mm won’t be the exact depth of cut output for each pass as with constant depth of cut but a value to not exceed. The algorithm will now look ahead at the model and split it into regions based on recognizing flats and calculate the depth of each pass to have them evenly spaced. The result is 2.6mm for each pass and a predictable cutting condition constant from shoulder to shoulder.

Vertical and Horizontal Regions, simple geometry

But what happens when the part geometry is more complicated? This first example of more complex geometry shows where we might have an uneven depth of cut occurring.

‘Constant Depth of Cut’ on complex intersection shows a thin cut over the crest of this geometry.

With no simple way to identify regions based on flat surfaces, how do we define the Region to split this part up?

‘Even Depth of Cut’ on the complex intersection

By using the inflection point(s) of the model, we can determine the regions to split and calculate the depth of cut evenly for complex shapes.

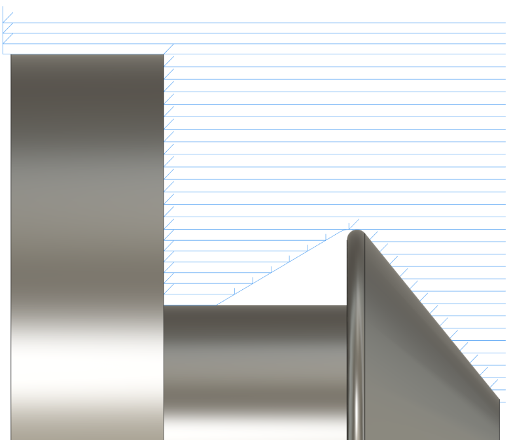

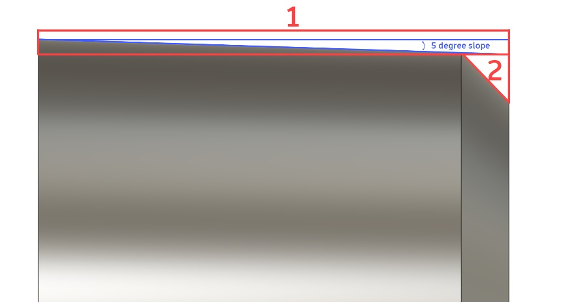

The last case is angled faces. For this instance, we can look at an NPT Thread example that has a 5-degree taper to the shaft. The algorithm will look at anything greater than 5-degrees as a region; anything less will be considered not a splitting region. Like in the tapered surface below.

‘Constant Depth of Cut’ on <5deg tapered surface

With no flat to determine the Region or an inflection point, we cannot clearly identify what is a proper splittable region to achieve an even depth of cut. In fact, this one, we will not be able to achieve an even depth of cut at all due to the angled surface. But, to eliminate the small remaining amount of material, we can determine what minimum and maximum of a region are for angled faces. This is why we built in a maximum angle of 5-degree for considering regions. If the angle is greater than 5-degree, it will not consider it a “flat” region. Giving us the best results below.

Regions for >5Deg slope

‘Even Depth of Cut’ on tapered surface of >5deg

We started with even depth of cut working for Outer Diameter and Inner Diameter roughing with almost every combination of setting except a few: no drag, Back cutting, and Rest Machining (working from casting).

We took some liberties with assumptions in the algorithm and want to open more options up for users to determine. For instance, Maximum depth of cut is the only input, so what is the minimum depth of cut? Currently, we handle it by Region. Any flat region that is less than the maximum depth of cut we do not consider a region as well. We will be looking to open a minimum depth of cut field to control that value better.

Take a look at these new manufacturing techniques. Not using Fusion 360 yet, try it today.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.