& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

Companies designing smart devices for the first time often consult third-party resources for expertise. IoT devices and ecosystems are sophisticated, so partnering with the right company can quickly pave the road to successful production. Device makers also face an ongoing challenge: “How can we pack as much hardware as possible into compact devices?”

A seasoned manufacturer can provide guidance and answer these burning questions. Your hunt will include plenty of research and considerations — keep these considerations in mind when choosing your manufacturer:

Some manufacturers shine in specific areas such as design, while others may excel at logistics. The ideal partner will have years of experience in your particular areas of interest.

It’s worth noting that IoT design encompasses more than the devices’ physical aspects. Many companies lack exposure to the entire product stack — including cloud systems, connectivity, mobile apps, software, machine learning, AI, and analytics. These foundational attributes help smart systems stand apart from the rest. Many manufacturers will hire external resources to fill this knowledge void, which isn’t inherently wrong, but OEMs must be mindful of communications challenges or increased lead times. In-house teams tend to work more cohesively.

Consider this: many IoT companies are startups bringing exciting new technologies to customers. For entities supported by investors, pushing a viable, profitable product out the door is essential. Unfortunately, this tends to happen before many other resources fall into place — marketing teams, for instance. The reality is that many businesses lack dedicated communications teams to help drum up market interest, and even established companies encounter similar hurdles.

This is where your manufacturer can lend a hand. Many companies who’ve fleshed products out from the design phase to production know them inside and out. They’re often in a superb position to market your IoT solutions. When manufacturing overseas, your manufacturer may be able to help you break into local markets — odds are they’ve already done it themselves.

You become a client the moment you enter into a contract with a manufacturer. They’ve won your business, and now it’s their job to steward you through the process. This process involves plenty of education, transparency, and dedication to your ultimate goal: designing and selling stellar products with as few hiccups as possible. You shouldn’t feel like an inconvenience, and requests for manufacturing analytics shouldn’t be mired in red tape.

Inevitably, production will hit some minor snags here and there. Your manufacturer should work with you to alleviate these woes and keep you updated. This follow-through is everything. Many manufacturers will fall silent once orders are placed, or money trades hands. Those passionate about you and your products will be actively engaged and excited to meet with you. An exceptional manufacturer will take the time to understand your IoT solution and apply past lessons learned.

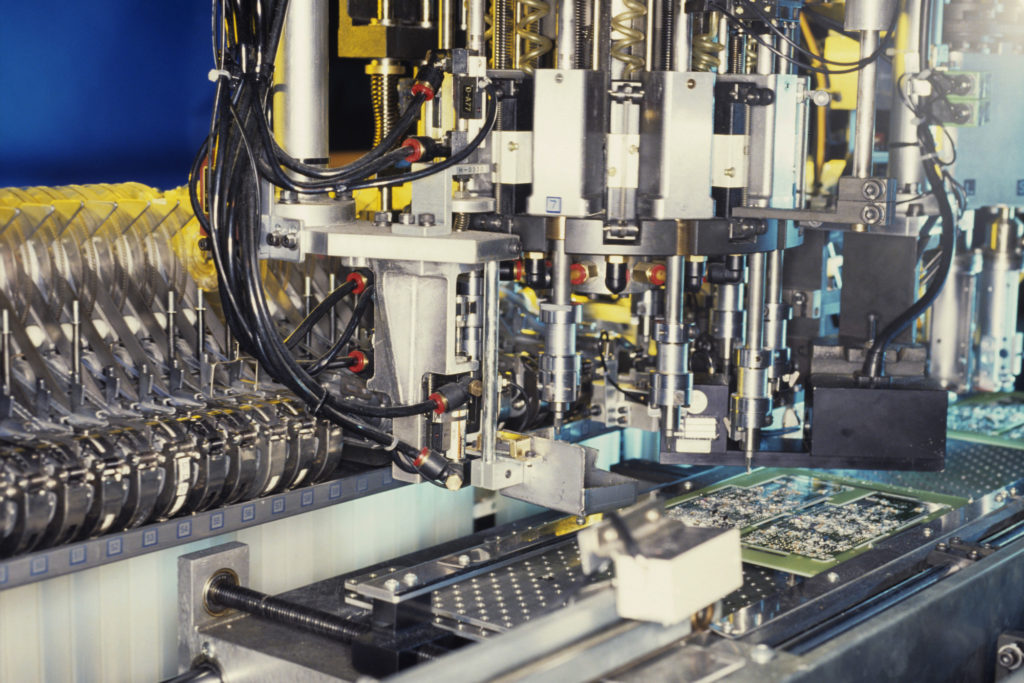

Like one does when purchasing a new car, it’s always worthwhile to scrutinize before signing on the dotted line. Checking out the manufacturing floor, workplace processes, and machinery can offer plenty of insight into a company’s operations. This friendly “reconnaissance” work is commonplace for most companies securing this manner of partnership. Are companies putting all of their eggs in one basket (a single industry, product type, or even manufacturing facility) or spreading themselves too thin?

Let’s say you’re developing IoT solutions for the mass market, yet have commercial ambitions as well. A manufacturer should be able to fulfill initial test orders. If your products catch fire, your partner must adequately scale production. Long-term planning will prevent future headaches, and evaluating manufacturing capacity is essential.

Integrated programs such as Fusion 360 help streamline the manufacturing design process, allowing for more effective product development, especially when it comes to IoT design. Manufacturers can look to Autodesk’s portfolio of tools for more ways to create their unique projects.

Try Fusion 360 today.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.