& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

In the rush for competitive differentiation, end products are becoming more connected, intelligent, and the processes to produce these products are becoming more automated and digital. Both end-products and process are being driven by digital data.

Unfortunately, the design and engineering of products have not changed for the last 30 years. Based on the design criteria, mechanical drawings of a concept are fully defined by a human on a computer, but this manual process only leaves time to uncover 1 or 2 potential design concepts that are by default limited to the imagination of the human behind the computer. Late in the conceptual design process, after the design concept is defined, simulation and/or topology optimization then takes place and once completed, then the design concept is tossed over the wall to manufacturing to figure out the best way to develop a physical prototype.

Sound familiar?

Generative design in Fusion 360 is your ideal co-creation partner. Fusion 360 generative design solves complex mechanical engineering problems faster, while at the same time, developing multiple design options for evaluation.

Fusion 360 generative design software can produce more design options faster than a designer or engineer can imagine them. Further, the design ideas are not limited by human bias—thanks to artificial intelligence (AI) and unlimited cloud-computing power. Fusion 360 generative design embodies the essence of design automation.

When humans and machines collaborate together, the outcome is greater than what either human or machine could achieve by itself. The result? More time and compute power to explore and be more creative. Generative design in Fusion 360 completes its computations and intensive calculations on the cloud (in essence, on Autodesk’s more powerful computer, AWS).

Fusion 360 generative design software delivers a significant number of potential design outcomes, manufacturing options, and relative costs to produce. This leaves the designer time to make decisions regarding style, aesthetics, and cost targets in order to better evaluate the customer experience.

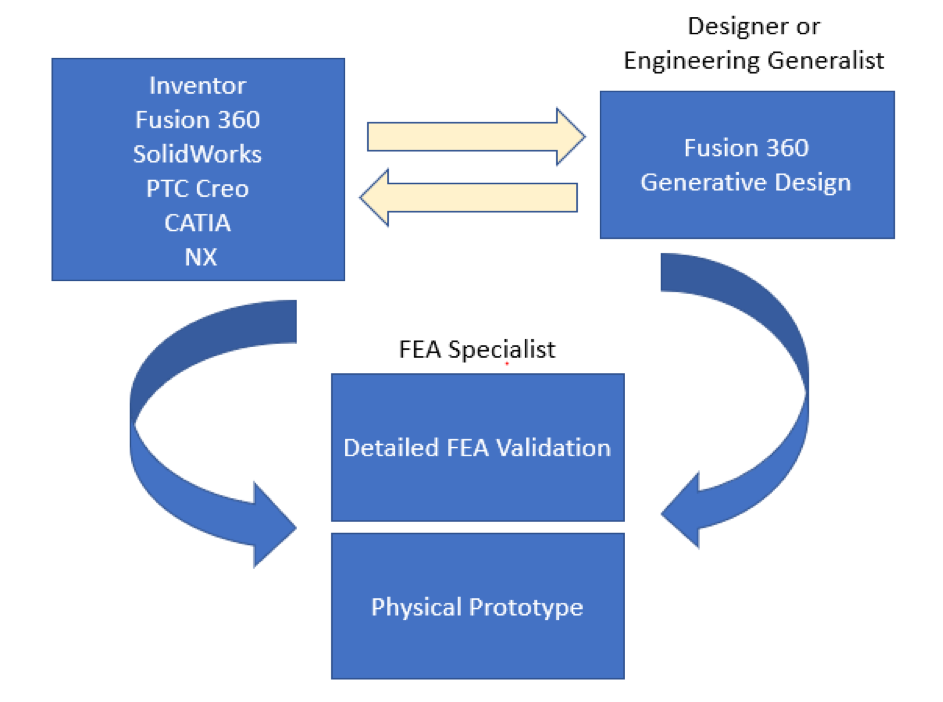

Generative design has been developed for Designer/Engineer Generalists, not a simulation or FEA Specialists. The product development team has purposely avoided any of the obtuse nomenclature and processes associated with FEA and has made the types of simulation performed by generative design simple to use for the for Designer /Engineer Generalists and avoids the intricacies of detailed analysis that FEA specialists expect (and are paid well to fulfill).

More importantly, generative design in Fusion 360 moves simulation to the start of the process instead of simulation being an afterthought or even worse, failure analysis that needlessly extends the product development process, adding costs and potentially missing business opportunities.

Finally, for the first time the manufacturing process is considered early on in the process along with simulation so that designs are not “thrown over the wall” to leave it in the hands of manufacturing determine how a design concept can be/should be manufactured after the fact.

Generative design in Fusion 360 is not only a specialist tool but also a generalist tool that becomes a normal process for each and every designer/engineer on every project. Engineers that are graduating get it. Check this out:

Above I have stated that generative design is a generalist tool, but it does not take the place of detailed analysis provided by an FEA Specialist. Generative design in Fusion 360 incorporates FEA analysis to quickly determine the design concepts that meet the performance specification and from an FEA simulation perspective will get you 80% or more of the way there, but detailed analysis by an FEA Specialist or physical testing may still be required to prove out the design. Your new process may look something like this, but you will get to the optimized design concept much faster than traditional methods.

Do not delay try a generative design with Fusion 360 today.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.