Elevate your design and manufacturing processes with Autodesk Fusion

Metal Additive Manufacturing is already established in specific industry verticals such as aerospace, defense, automotive, and medical applications. However, the cost of entry is still too high for the mainstream adoption of Metal AM. Suppose a company wants to benefit from 3D printing with metals. In that case, they would need to invest in expensive hardware and build up internal knowledge to deal with the inherent engineering challenges of laser powdered technology such as printing speed, distortions due to residual stresses, and the need for post-processing.

“Companies struggle with the decision to invest in those additive manufacturing processes because they have two problems. The first one is the financial risk, and the second one is not having enough educated employees.” — Dawid Ziebura (CTO, LMI)

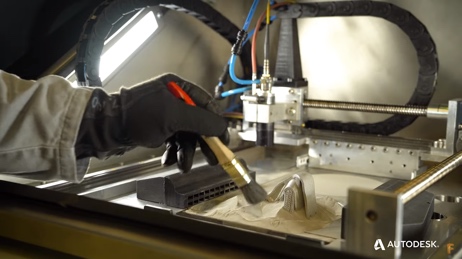

Laser Melting Innovations (LMI), a spinoff from Fraunhofer ILT Aachen, is trying to change this by providing a low-cost, entry-level system that allows users to find the right applications. They have created a machine called Alpha 140 that costs less than $120,000 USD that can produce high-quality metal 3D printed parts.

Alpha 140 from Laser Melting innovations offers an optimal solution for the tool-free production of metal parts, especially for small and medium-sized companies.

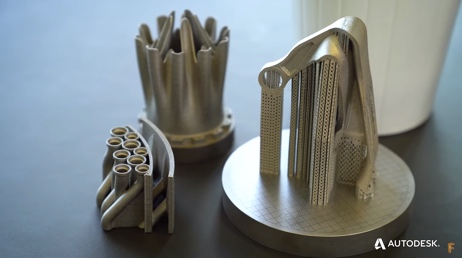

Having access to a printer is only one piece of the puzzle. To truly benefit from Metal Additive Manufacturing, companies need to focus on design for additive, parameter development, material science, and education. Coming up with an application for metal additive and making sure it is designed with the manufacturing process in mind requires powerful design and print preparation software.

“Our vision was actually to bring additive manufacturing into the masses, so companies and universities can build up their own knowledge within this technology and generate their own competitive advantage.” —Mirjam Henkel (CEO, LMI)

While there are several specialized solutions for addressing isolated tasks for design and manufacturing for AM, having a fragmented workflow results in data islands and hinders innovation. An end-to-end design and manufacturing software offers a continuous data flow, allows users to iterate their designs, orientations, supports structures and parameters without the fear of losing time and data.

“The current workflows we see in the industry today are ones where you have different specialized applications for each job. Fusion 360 offers all this in one integrated workflow.” — Lukas Fuhrmann (Product Owner Additive Manufacturing, Autodesk Inc.)

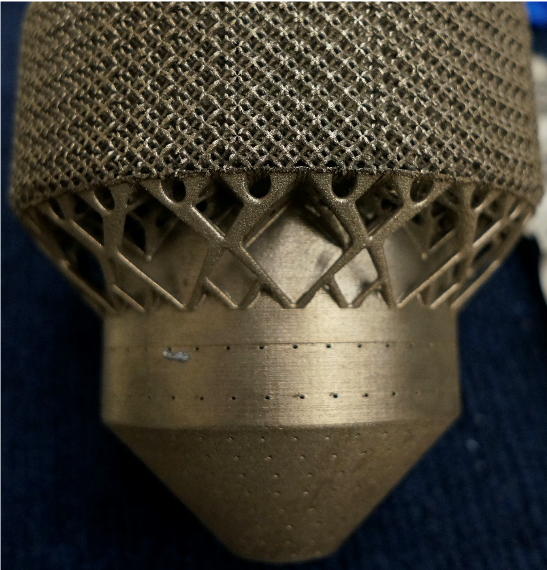

Incorporating additive manufacturing-specific functionality into a cloud-based CAD/CAM software enables a whole new design process and accelerates the industrialization of Metal Additive Manufacturing for numerous applications. For example, based on the software’s feedback regarding possible print orientations, a designer can change their model and minimize the need for support structures by incorporating them into the design where large overhang angles are present.

Latticed support structures were incorporated into the design of this 3D Printed metal component using CAD, NASA Marshall Space Flight Center, Huntsville, AL

In a disconnected workflow with multiple tools, this process requires a lot of back and forth between various departments within an organization and a lot of file transfers between incompatible software.

Adding direct support for 3D printers into a design and manufacturing software enables faster iterations, as necessary information regarding the printing process is available during key steps of the workflow. Access to this information ensures thorough consideration during critical design and manufacturing decisions.

Just like in hardware, price flexibility plays a critical role in software. Fusion 360 offers the best-in-class pricing model and ensures users only pay for what they use. Advanced manufacturing capabilities, such as Metal AM, is considered an Extension to the core Fusion 360 functionality and can easily be turned On/Off by the customer depending on their needs. The flexibility to turn extensions On/Off as needed, creates efficiency for the user without being tied to long term contracts and pricing complexity.

Combining dependable yet low cost of entry hardware and flexible yet intelligent software solutions will enable mainstream adoption of Metal AM.

Try Fusion 360 today.