When you rent like me, you’re at the mercy of your landlord when it comes to home improvement. Nothing makes me feel cozy on a cold day like an open flame warming the living room, but there’s no way my landlord is going to spring for that.

Using an ethanol burner (carefully following the safety instructions), it’s perfectly safe to have an open flame without the need for a vent. With the right kind of fuel, there is no danger of harmful fumes tainting your indoor air quality.

The companies that make ethanol fireplace burners also make some very nice stand-alone fireplace fixtures, but for the limited space of my Bay Area apartment, I need my furniture to be multi-purpose. Hence, the Fireplace Coffee Table.

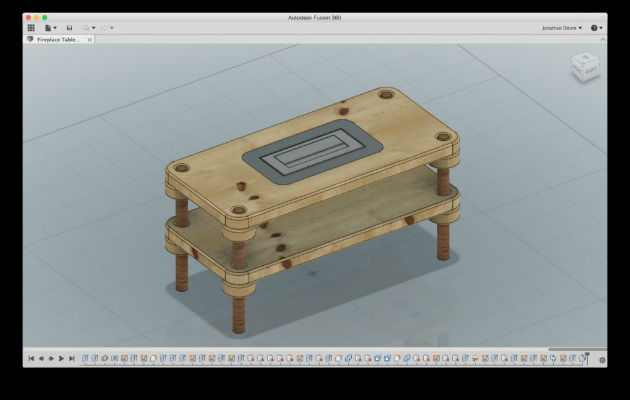

This is the first furniture piece I’ve designed using my Wooden Nuts and Bolts idea, so I based the table on 4 threaded wood legs with nuts for rigidity. I designed it to be 2-tier, because my current coffee table with 2 tiers is really practical: you can move all the books, magazines, and empty coffee cups to the lower tier when you want to put a laptop on the top tier to watch a movie- or in this case, when you want to light a fire!

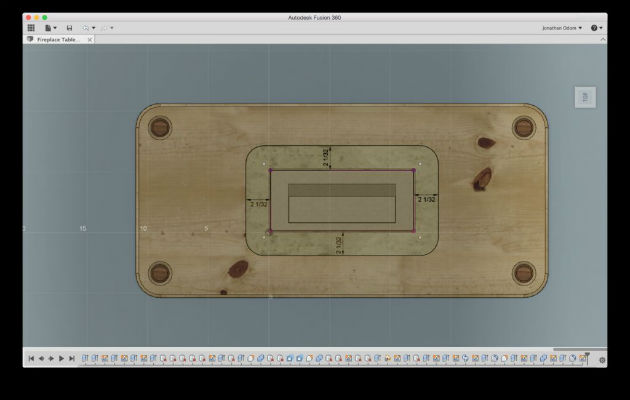

The manufacturer’s instructions call for specific clearances around the burner surface to combustibles. So to play it safe, I designed the table to have a 2 1/2” deep cast concrete surround for the burner insert. I wanted the top of the burner to be flush with the top of the table as well, so I designed the cast concrete part to have a 1/8” thick indentation. I left a 1/16” gap in the model for wiggle room between the burner and the concrete.

Fusion 360 is my go-to for furniture and product design these days. It’s free (for 1 year with an “Enthusiast” license after a 30-day free trial), and it’s got all the tools you need to make this project work.

Fusion is great for this kind of work for a number of reasons. It’s easy to simultaneously work in 2D and 3D, and also to think in 2D and 3D. The workflow focuses on 2D sketches becoming 3D objects in the solid modeling environment. Since I tend to build my projects out of sheet materials, the parts are broken down into flat, contour cut components. With Fusion, you can project geometry from other parts onto sketches so that they update automatically when you alter the part they’re related to.

Fusion gives you clean, accurate, rational vector geometry that can easily be turned into cutting templates if you don’t have access to CNC machines. If you’re not used to cutting out complex shapes designed in the computer, check out my Digital Fabrication by Hand Instructable.

The concrete came out beautifully for the most part. The top surface was very smooth without any break-outs or cracking.

Having sealed only the cutout though, there was a small amount of wicking in the top surface of the table from the edge of the concrete. Sealing the entire piece before casting would probably fix this. One of the shop guys also suggested just using vaseline around the edge of the cutout, which seems like it would work.

I added some joining dowels to the inside edge of the cutout before I poured the concrete so that the cured concrete slab wouldn’t rely completely on the inside edges for structural support. Once the concrete was cured, I also added some extra wood structure to the underside with liquid nails- better safe than sorry!

I also used Concreteworks’ concrete polish for the finished surface: wax-on / wax-off with a rag and this was done in 20 minutes. The result is a smooth, shiny concrete surface that would be perfect without the wicking at the edges.

Show All 10 Items

- Thread one nut half way down the length of each leg. These positions should be consistent, since they will set the height of the lower tier.

- Insert the leg into an unthreaded hole on the lower tier.

- Thread another nut 1 1/2″ down the top of the leg.

- Place the top tier and screw in the leg until its top is flush with the table top.

- Tighten the second nut against the bottom of the table top until it’s rigid.

Repeat these steps for each of the other 3 legs. This is a good time to choose the pieces that came out the most perfect for the most visible placement.

The great thing about making this table with wooden nuts and bolts is that it’s endlessly adjustable. Flip the table to its upright position and adjust the nuts until everything is flush and level.

This construction is ROCK SOLID. It’s got serious lateral stability and can take a lot more dead load than it needs to. The wooden nuts & bolts scheme makes for a very robust finished product.

This is a seriously versatile piece of furniture. The ethanol burner closes with a steel tool that’s included, and after 15 minutes it’s cool to the touch. You can use it as a fully functioning coffee table with a level surface 95% of the time, then clear off the top, pour in some fuel, and read a book by the fire on a cold night.

The burner is guaranteed by the company and comes with a complete set of safety literature. Follow the instructions and use common sense, and this is an awesome addition to the home you don’t own.