Grillo is developing new technologies that provide life-saving warnings to populations that live in seismic-prone areas. With the help of Fusion 360, Grillo looks to expand the network of sensor installations globally.

Inspiration for an Early-Warning System

Based in Mexico City, Grillo founder Andy Meira worked in Haiti with the Clinton Foundation following the earthquake of 2010. After moving to Mexico City in 2012, a very seismic region that also suffered a devastating earthquake in 1985, Andy experienced 3 strong earthquakes registering over 7 magnitude. It was here that he was inspired to look for a way to connect with the government’s earthquake early-warning system (SASMEX), which transmits ground movement warnings via specific coded radio transmissions.

Since these government devices are quite costly, Andy looked to invent a low-cost affordable receiver, which he later names, Grillo (Spanish for “cricket”). In his initial prototype, he encased an Arduino inside laser-cut acrylic pieces, glued together:

After his initial prototype successfully alerted his family of the next few earthquakes, Andy decided to commercialize the product in order to allow Mexican citizens to connect directly to their government’s early-warning system. His new company, Grillo, formed in 2014 and was later accepted to accelerator, 500 Startups. The early-warning became the most successful crowdfunded project in Mexico, attracting both national and international press coverage.

The Road to Manufacturing

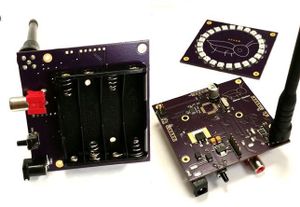

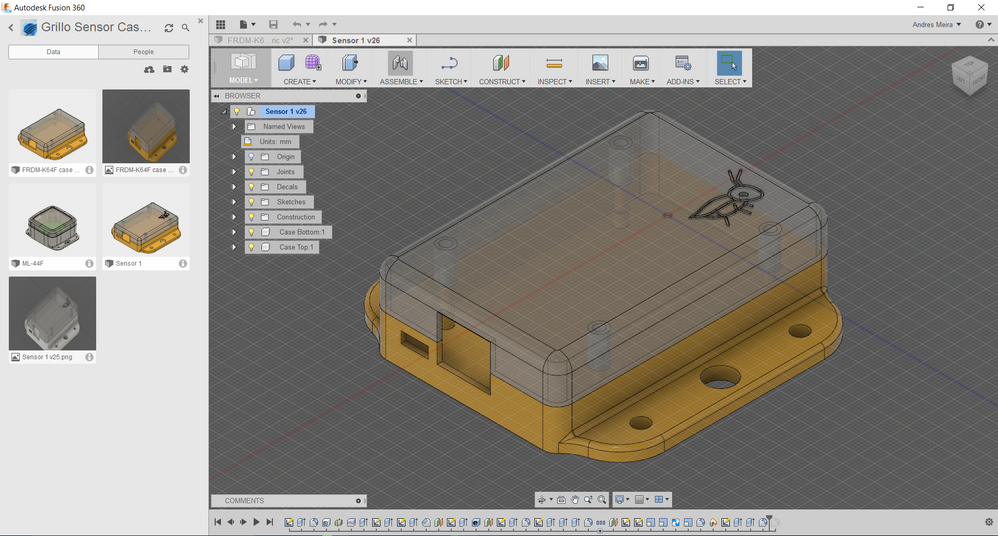

To develop Grillo’s prototype a number of design modifications were done for plastic injection molding and electronic PCB fabrication. The design of the enclosure was done solely in Fusion 360, which allowed the team to rapidly prototype different variations and create 3d prints to physically visualize and test the designs. Fusion 360 was quite easy for the team to learn and get up to speed quickly. They shared files in the cloud and easily collaborate with other team members. The team’s final design files were exported to a machine shop that developed the mold for manufacturing.

A Glimpse of What’s Ahead

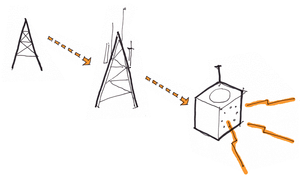

Grillo is now focusing on improving the way earthquake warnings are executed by leveraging technologies such as the Internet of Things and Big Data to create new sensor infrastructure, a cloud processing system and notification APIs.

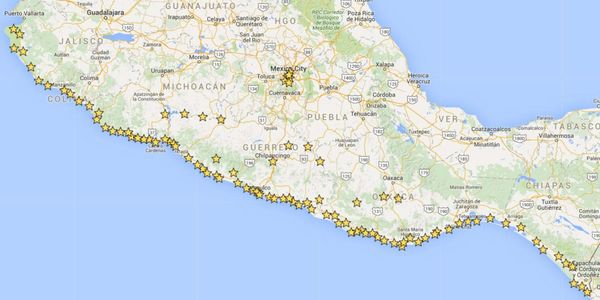

With the support from the US Agency for International Development, Grillo will design the next generation of earthquake warnings that can be transmitted via the internet and deployed anywhere in the world. A large network of sensors is currently being installed in Mexico.

Grillo is working with a team of seismologists and data scientists to process real-time acceleration data in the cloud. The newest sensor enclosures are again being designed with Autodesk Fusion 360, here’s a look at the new enclosure:

New tools for rapid prototyping, and cloud processing of data have allowed Grillo to grow and evolve quickly. Without these tools, Grillo believes a project like this would not have been possible 5 years ago.