& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

2 min read

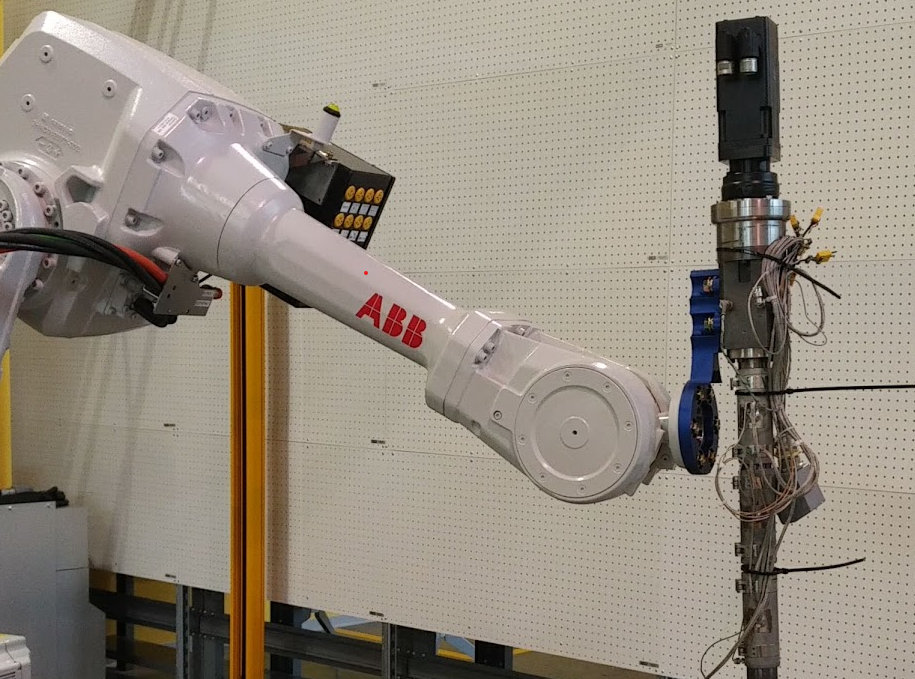

Robotic manufacturing continues to grow and evolve at an extremely rapid pace. New opportunities include collaborative “cobots,” industrial IoT, connected robots, and niche applications in small and mid-sized manufacturing operations.

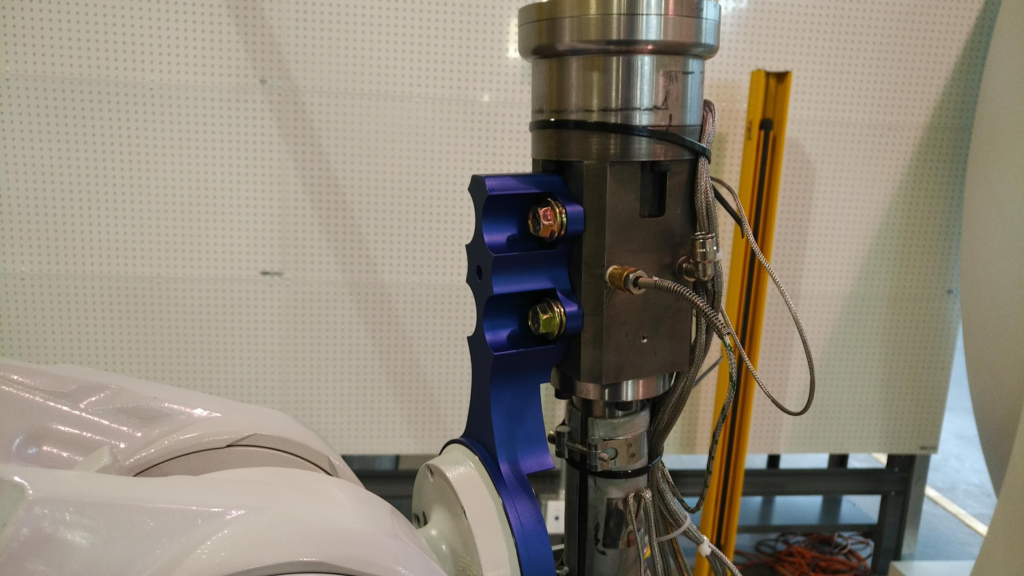

This last robotic manufacturing trend depends on the ability to design end effectors quickly so that the same robotic arm can be used for multiple tasks in one shop—whether it be to pick up objects, drill, cut, or extrude material. Effectors also must be designed to hit a “sweet spot” of structural stiffness, durability, and weight.

Generative design can meet all of these objectives at the same time. At the Autodesk Generative Design Field Lab, Technical Innovations Manager Rossen Maltchev explained why this is the case.

“We are helping a client create an extruder that will be mounted on a robotic arm,” he says. “In this case, we were not redesigning an existing effector but rather creating one from scratch. We knew the loads, and we knew what safety factor we wanted. Generative design was an ideal approach.”

You can indeed use generative design to create unusual organic shapes that are better suited to additive manufacturing. However, they can also be instructed (or “constrained”) to produce designs that can be milled on a conventional CNC machine.

“This is a relatively simple part, so you might not think of using generative design at first,” Maltchev says. “But by limiting Fusion 360 to 2.5 axis manufacturing, we got designs that were very close to what a human engineer would have come up with—just much, much faster.”

While it might take a designer working in CAD a few days to develop a design for the effector, generative design came up with multiple options in just a few hours.

“It’s not only faster than a human designer; it can explore multiple ideas simultaneously,” Maltchev says. “Plus, the designs it produces are fully FEA validated to the desired safety factor, so you can be sure it won’t bend or break.”

The process in Fusion 360 is straightforward. Maltchev characterized the loads and reviewed the initial ideas, including 2.5-axis and 3-axis options. After selecting a final design direction, Maltchev 3D-printed a prototype to ensure a proper fit on the arm. He did a small amount of cleanup to the design, and then the software created a 3D model ready for delivery to a 3-axis mill for machining.

“We saw some ideas with a 3-axis constraint as well, but they would’ve taken much longer to machine,” Maltchev says. “Some of the options weighed slightly less, but the difference was not significant. And those designs would’ve taken several hours to mill with multiple setups and toolsets. The 2.5-axis design took about 30 minutes, so it was much less expensive to make.”

In fact, Maltchev notes, one advantage of Fusion 360 is the ability to compare estimated manufacturing times and costs from within the software and try various materials to design a lightweight component that maximizes structural performance at minimal cost and maximum speed.

“I really recommend using generative design with a manufacturing constraint for new parts like this,” Maltchev says. “It minimizes the time you spend finessing designs in CAD and maximizes the time you spend on actual engineering.”

The Autodesk Generative Design Field Lab is located in Chicago and was designed to show our customers what generative design is, how you can use it, and how it will change the future of manufacturing. Learn more here.

Download Fusion 360 today to explore the benefits of generative design with your next project.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.