3D printing is often viewed as an environmentally friendly manufacturing method because of its reduction in waste material. It’s also shaking up supply chains by allowing localization, consolidation, and reduced inventories. However, every manufacturing process has an environmental impact, and additive manufacturing is no exception. In this article, we’re going to look at the FFF (Fused Filament Fabrication) 3D printing process and how making changes to your workflow could reduce your parts’ impact on the environment.

The three key FFF 3D printing sustainability aspects to consider are a part’s lifecycle, material choice, and power consumption. Making sure your parts are as environmentally friendly as possible is a balancing act between these three factors.

Part lifecycle

Considering the entire lifecycle of the part is a key stage of the FFF 3D design process that can sometimes be overlooked. Try to consider all areas of the design lifecycle, from initial manufacture to end of life.

It’s impossible to think of everything during the design phase, and one of the best things about producing a prototype is that once your part is in your hand, you can quickly see any mistakes or features that you may have forgotten. But being as accurate as possible during your early design stages can save unnecessary printing and reduce wasted time.

Using the proper infill patterns and density can be a great way to reduce how much material you’re printing. If you are 3D printing a functional part, use infill structures, and a higher infill density to maintain good structural integrity. If the part is purely aesthetic, consider using reduced infill densities or, even better, the vase mode, which will print your part as a hollow body.

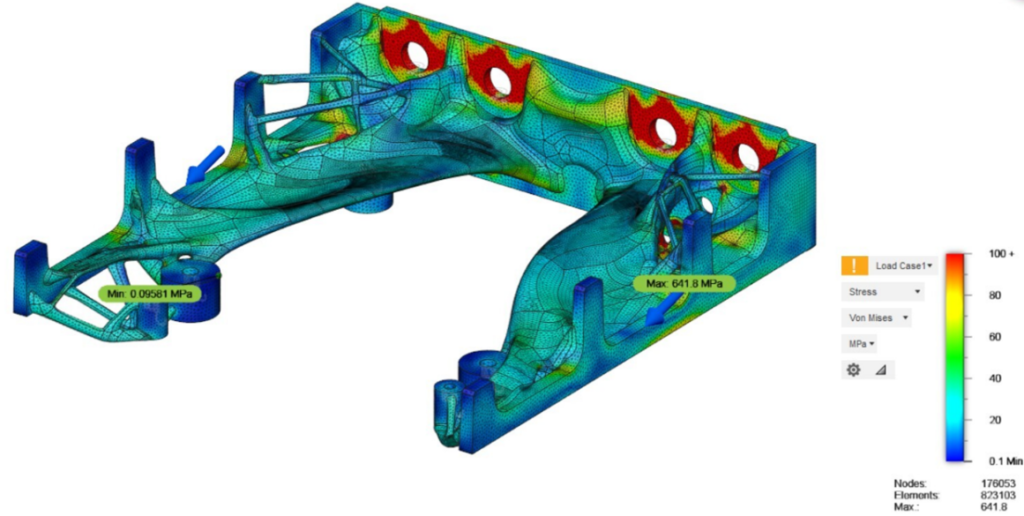

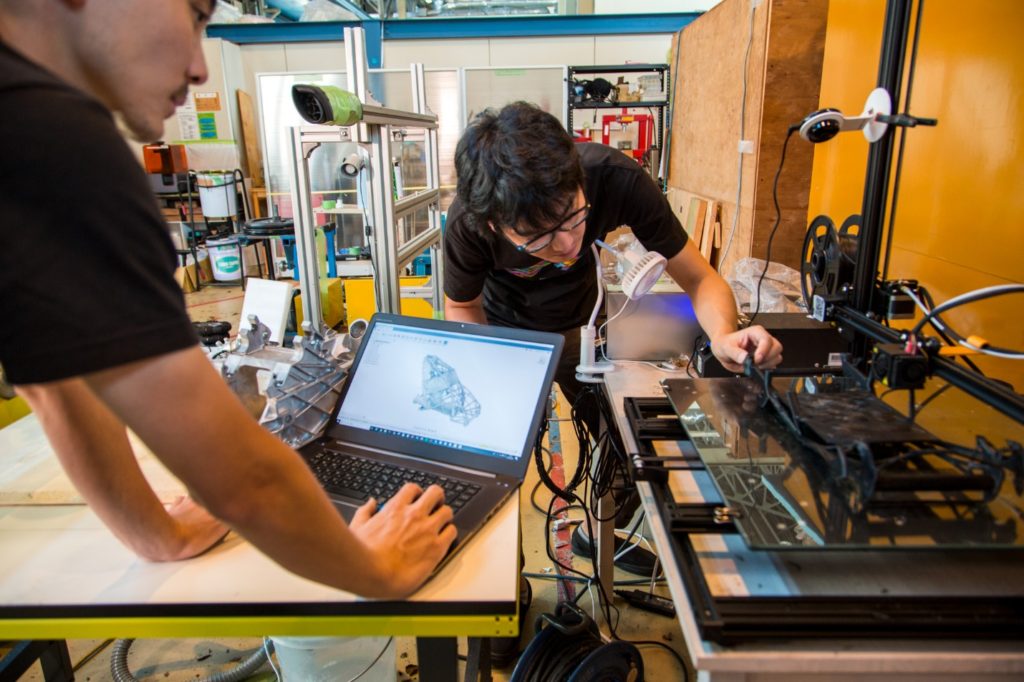

If you are using FFF 3D printing to produce prototype parts or mechanical components, try to ensure your designs are as optimized as possible. Using the range of simulation technologies within Fusion 360 can be a great way to ensure that your part is strong enough for its application and isn’t overengineered and using more material than required.

Finally, try to avoid using adhesives in assemblies of parts and instead use mechanical fixtures wherever possible. This allows the user to fully disassemble the product and dispose of every component responsibly at end-of-life.

Material Choice

Understanding the properties of the materials can ensure that you choose the right material for your part. For example, if your 3D printed component needs high impact resistance, using a nylon filament will ensure that your part has a longer usable life than the same part in ABS.

PLA is the better material choice environmentally speaking. It’s arguably the easiest material to print with, therefore reducing the likelihood of failed prints, and it’s a bioplastic, which is created from plant-based materials. Or even better, use rPLA, which has almost the same properties as PLA, but is produced from factory waste material.

Also, consider embossing your selected material’s recyclability icon onto your components, especially if you plan on distributing the parts to others. This will guide the user on how to responsibly dispose of the part at its end of life.

Finally, consider disposing of your printing waste (support material, failed parts, etc.) responsibly. Today, most additive manufacturing materials are treated as “Other Plastics” (Category 7) and are unfortunately not accepted at most curbside municipal recycling programs. But there are many independent plastic recycling and processing companies that recycle materials that aren’t processed by the local pickup service.

Power Consumption

An often overlooked but critical factor when considering all manufacturing methods’ environmental impact is the power consumption of producing a part. To reduce the power consumption of a print, try to optimize your print settings as much as possible to reduce overall print times. By reducing the amount of time your parts take to print, you reduce the amount of time your printer is drawing power, therefore reducing your environmental impact.

We’ve found that choosing infill patterns like the gyroid, star and rectilinear patterns can massively reduce print times when compared to some of the more complicated patterns, such as the Rhombille and Auxetic patterns. A future blog post is in the works to share some of the research that we have been doing in this area.

Final Thoughts on FFF 3D Printing Sustainability

FFF 3D printing as a manufacturing method democratizes manufacturing, allows for previously impossible designs, and speeds up product development cycles. It has had an undeniably positive impact on the design and manufacturing industry and has become a mainstay in many companies’ product development processes.

Designing for manufacture (DFM) is a vital stage of the design process, and considering the disassembly, disposal, and environmental impact needs to become a part of this stage. By considering the three factors described above during your DFM process, you can limit your impact on the environment.

Ready to take your FFF 3D printing process to the next level? The Fusion 360 Additive Build Extension unlocks extra additive manufacturing technology that lets you produce lighter, stronger, better-performing parts whilst reducing material wastage and cost.