FabShop is a French design and consulting firm focused on additive manufacturing, particularly 3D printing. We spent some time talking with FabShop’s creative director, Samuel Bernier to learn more about his design studio and how they’re using Fusion 360 to inspire creative innovation. Here’s what Samuel had to say about his makerspace.

Finding the Right Tools to Work Together

Our design studio is well known in the world of additive manufacturing, having created some of the most famous 3D models you’ll find online—the articulated elephant being our super star. Back in October of 2014, Autodesk asked us to operate the Pop-Up Gallery event workshop space in Paris. We installed our entire lab in the Gallery and sen

We had been using and teaching Autodesk’s 123D apps since their release, but still were using other software for our professional design work. Since our team of designers and interns all had experience with different types of design tools, it presented many challenges for us. We were using a total of ten different 3D modeling software packages—an absolute nightmare when collaborating in team projects.

As Creative Director of le FabShop, I had been looking for an alternative that could combine the form freedom of Autodesk Maya, with the simplicity of Autodesk SketchUp. I needed a tool that could handle complex skins like Rhino but still offered the technical advantages of Autodesk Inventor and Solidworks.

Fusion 360 Fits the Bill

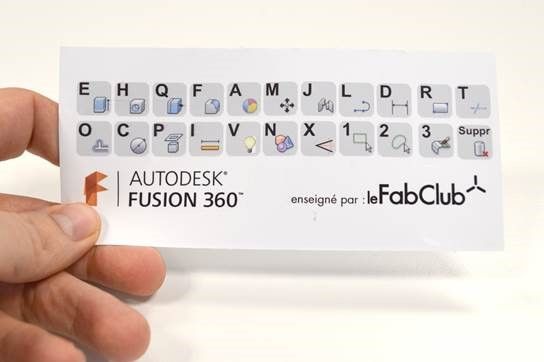

Fusion 360 is exactly what we’re looking for—it’s affordable, connected and compatible with multiple platforms. It has drastically changed the way our design studios work as teams and work with our clients. Having both a studio and a makerspace, it fits the bill for the disperse activities we engage in.

Here’s the top 5 reasons why Fusion 360 is the perfect design tool for us:

- We can operate our CNC and 3D printers directly within Fusion 360’s modules or extensions.

- Our designers can easily switch from solid 3D modeling to free form modeling, without having to toggle between multiple software packages.

- Our project design history is captured and can be edited, which is absolutely necessary once you learn how it works—I couldn’t live without it.

- It allows us to generate renderings quickly.

- We can access our work from anywhere with a connection and share it easily with the A360 web application.

Since beginning to work with Fusion 360 within FabShop, we are convinced that it will quickly grow among the industrial design community and we are excited to spread the word that a software dedicated to designers and makers finally exists!