& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

We created our Machining Fundamentals series to help you brush up on your CAM knowledge, whether you work in a machine shop or are just getting started. In-house machinists at our Birmingham Technology Center host each episode and provide a detailed overview of a tool/process. In the last edition, we covered lathes. Here we have an introduction to post processors, where you’ll learn all about post processor files: what they are, why we need them, and where to get them to use with Fusion 360.

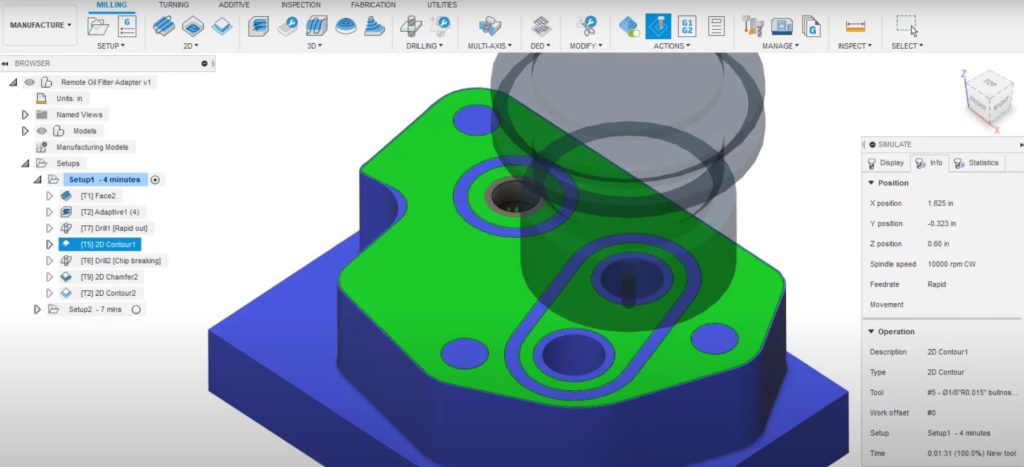

Post processor files, commonly called post processes or simply posts, convert generic toolpath information into NC code format that machines can understand. When we program a toolpath inside of Fusion 360 or any other CAM software, we’re defining information, such as the position of the tool, which tool to use, and many other aspects. Each machine interprets this information in a different format.

So, why does each machine needs a different NC code format? Why can’t they all take the generic toolpath information directly out of Fusion 360 or any other CAM software? In addition to the many different machine makes and models available on the market, there are various machine controllers. The machine controller is kind of like the operating system of the machines. They’re similar to an operating system on a computer or a mobile phone. Each of these controllers uses its own language and interprets information differently. In other words, the NC code is in a different format.

Some machine manufacturers will allow you to select the control that you have on a machine. For example, here in the Birmingham Technology Center, we have one DMG machine that uses a Siemens controller and one DMG that uses a HEIDENHAIN controller. Other machines come with a standard control. The machine we use in this video is a Haas machine that has a Hass controller. Each control type has its own language and interprets NC code differently, meaning that we need to output the NC from Fusion 360 to match.

Another reason why we need post processes is that even within a machine controller type, the machines themselves will vary, and we need the post to reflect this. Things such as the machine’s kinematics, whether or not it has rotational axes, the access limits, particular settings are all necessary considerations. Even if you have two machines of the same make and model, you may still need two different post processes, one for each. As a result, it’s essential to correctly set up your post processor for the particular machine you will use.

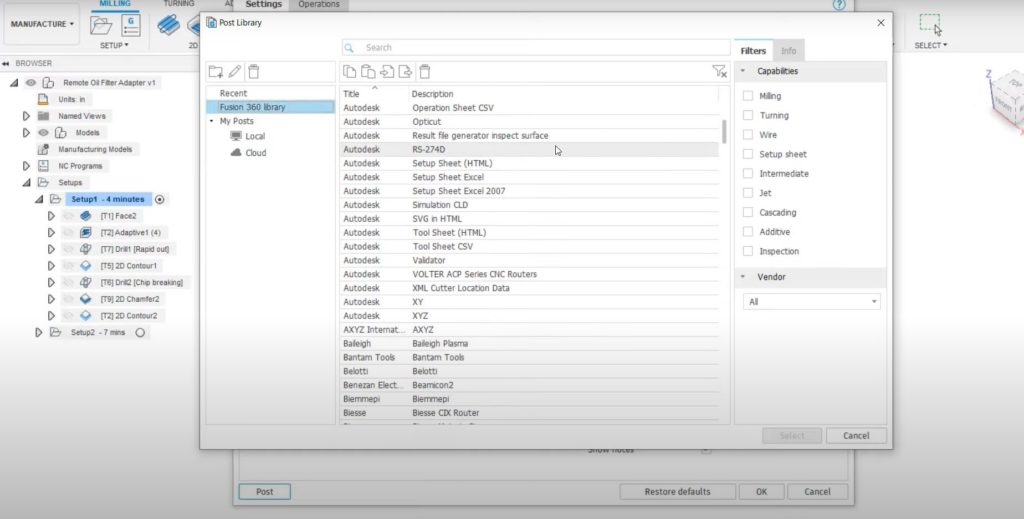

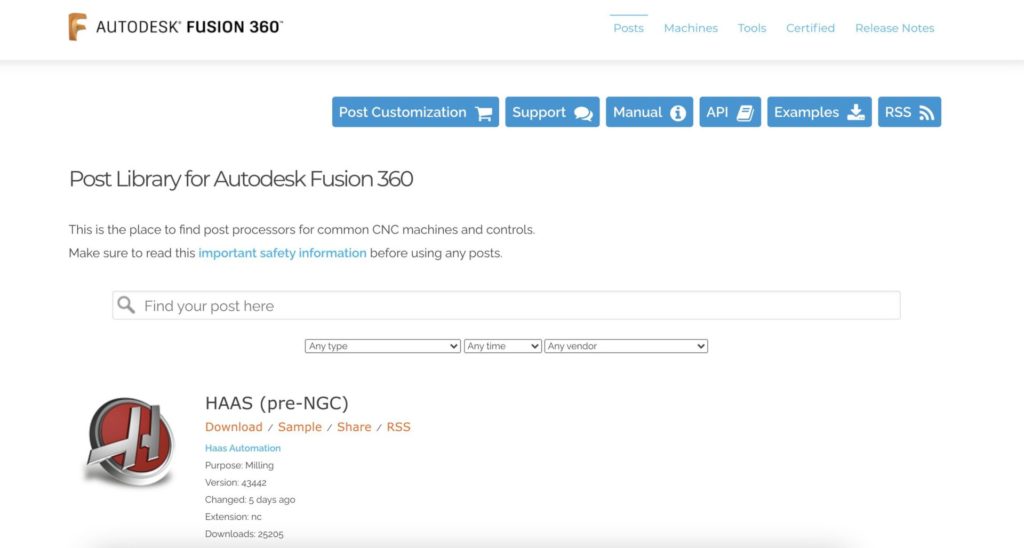

Where can you get the correct post processor file? With Fusion 360, all post processors are available for free. You can either select posts from the list of installed posts or download the one you need from our online Fusion 360 Post Library. The library includes hundreds of post files. Simply search for the controller or machine you have and download the correct post. You can then use your post in Fusion 360 at the point of creating NC code. These post files are also all open source for editing if you wish to do so.

You simply need to create an NC program item when you have two parts ready to post out. Once you make an NC program item, you can select which operations you want to post and the correct post processor. At this stage, you can also edit any post properties to configure them to your machine. For example, we can select which rotary axes are available on the machine. When you’re ready, select the post, and the system will create your NC code file. You can then put your NC code file onto your machine’s controller, and you’re ready to run.

That was a brief introduction to post processors, which you hopefully now understand the need for and the basics of how to use them with Fusion 360. Stay tuned: following this episode about milling tools, we’ll publish Machining Fundamentals episodes weekly. Future topics include toolpath types, NC code, work coordinate systems, and more.

In the meantime, download Fusion 360 to start machining smarter today. Learn more about how to maximize your machine with Fusion 360 here.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.