What is trace width, and why is it important to consider when designing PCBs? This article addresses these questions and more.

Trace width is one of the most critical factors of any Printed Circuit Board (PCB) design. Anyone who has a keen knowledge of circuit design is at some point faced with the challenge of deciding the proper trace width. Inexperienced designers tend to use the default trace width given in the PCB layout software. And this might work to a certain extent. Those who know electronics would probably look at the default width and intuitively know that it’s too narrow for some tracks, particularly for power supply and ground connections. You might bump it up a bit to something that “feels right” but not know how to set the appropriate widths in your design scientifically.

What Is a Trace?

Let’s start with the basics; A PCB trace is a thin line of conducting copper placed on a non-conductive or isolated base material that carries the signal and power to the whole circuit. A copper trace has a specific width, which we call trace width, and has a particular height or thickness.

Typically, the PCB thickness of this copper layer is fixed, and PCB manufacturing company specifications determine it. You measure PCB thickness in ounces per square foot in the United States. For typical PCBs, the most common copper thickness is 35µm which is equivalent to 1oz/sqr ft (we would say, 1oz Copper).

So in our design, we have control only over the width of the traces. For most manufacturers, the minimum trace width should be 6mil or 0.152mm. That limitation comes from their manufacturing (etching) processes and the target yield. But to have some tolerance, we generally use 10-12 mil or 0.254-0.3 mm traces.

What Factors Are Essential for Trace Width?

To understand why different trace widths matter, we first need to understand their difference in a circuit. In a standard PCB, there are two main types of traces: signal traces and power traces.

Signal Traces

Signal traces are those which convey some data. In digital or analog signals, having different trace widths generally doesn’t make much difference in simple PCB designs but is vital in RF/Analog and high-speed digital designs. In this type of design, trace impedance is an essential consideration since trace width and impedance have an inverse relationship. We’ll talk about that in the Impedance section below. We’ll talk about that in the Impedance section below.

Power Traces

On the other hand, power traces require some more attention because these traces are responsible for carrying power to each of the components in the circuit. There are two reasons for using different trace widths in a PCB design.

1. Current Carrying Capacity

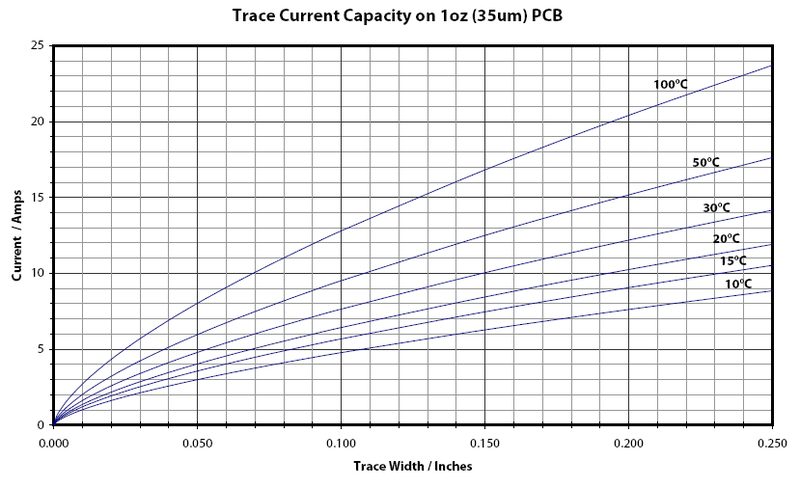

Current carrying capacity is the first and most obvious reason. Why? The relationship between the width of the conductor and current carrying capacity is straightforward. The cross-sectional area of a trace and allowable temperature rise determine how much current a trace can carry. The cross-section of the trace is also directly proportional to copper thickness and trace width.

As we increase the current passing through any given trace, the temperature also rises. The trace needs to contend with that temperature rise. A simple way to ensure this is by increasing the width of that trace.

The IPC-2152 standards are the place to start when determining trace widths. These standards use empirical data to generate the tables for calculating current limits for a given temperature rise. Working with a PCB trace width vs. the current table is excellent to evaluate your PCB trace width/cross-sectional area. This table allows you to effectively determine an upper limit on the permitted current in your traces. Given the infinite variables in PCB stack-up, you need to analyze the PCB using simulation to measure current density and temperature rise accurately. But for most typical boards, the IPC tables are good enough.

Here is a chart that shows several trace widths and corresponding current values that will limit your temperature rise to 10 °C with 1 oz/square feet copper weight. This chart should give you an idea of the most suitable trace width in your PCB design.

Several online tools can calculate the required trace width to carry rated current while keeping the trace temperature below a specified limit. Actual results may vary depending on application and conditions.

2. Trace Impedance

Specific spacing and impedance may be required for high-speed circuits to minimize crosstalk, coupling, and reflections. You must calculate sensitive data lines such as RF/analog traces and high-speed traces. For high-frequency signals such as GHz bands, PCB traces don’t act like simple connections.

Every copper trace has some series inductance and internal resistance, which is easy to overlook for simple low-speed designs. But in high-speed designs, trace inductance and copper surface roughness with the skin effect will increase and likely affect the board’s performance. Additionally, every signal trace holds some capacitance value between its return path and other nearby traces.

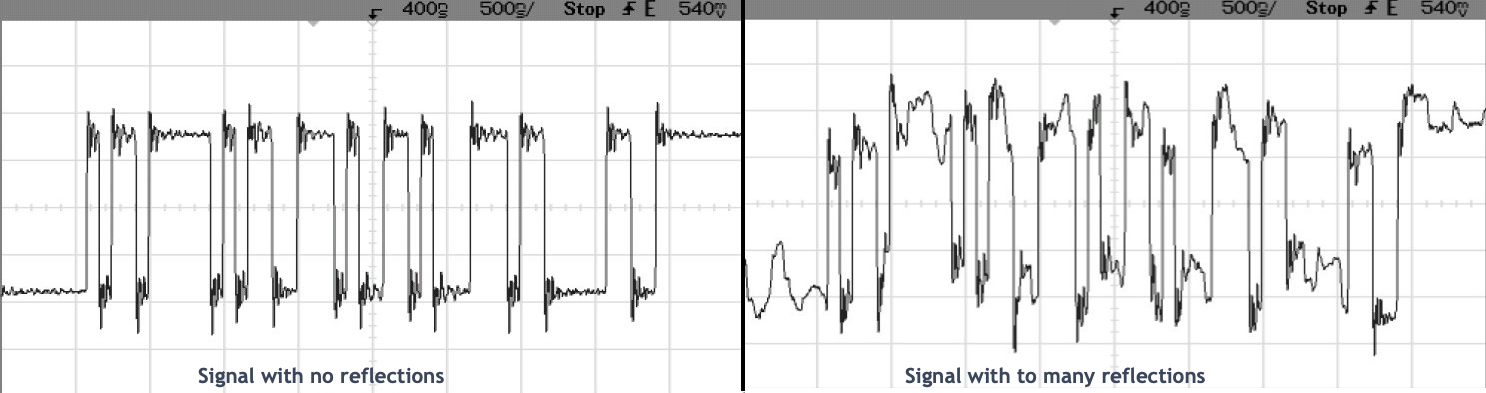

Trace Width and Signal Reflection

Signal reflection is an essential issue in the design of high-performance electronic circuits. The phenomenon where some portion of the transmitted signal reflects towards the source is called signal reflection, and signal reflection is undesirable because it causes signal distortion and oscillations.

Signal reflection in PCBs largely depends on the shape and route of traces. Trace discontinuities come into play whenever a trace changes direction, shape, or interfaces to a component. For example, when a trace bends at an angle of 90 degrees, trace width changes significantly. At the point of bending, the trace width is 1.414 times higher than the actual trace width. This change in trace width leads to a change in impedance and hence causes signal reflection. Professional PCB designers are aware of such issues and therefore avoid sharp bends and uneven trace widths.

If left unattended, these factors can significantly deteriorate the system’s overall performance since impedance will differ at different points in the signal path. Trace coupling, especially when signals cross-plane splits and voids, causes crosstalk.

Considerations While Designing High Power PCBs

Keep Traces Short

Every conductive material has resistivity. Therefore trace resistance increases as the trace gets longer or narrower. When current passes through the trace, it leads to higher power loss due to Joule heating. Since the wasted power converts to heat, the longevity of the board reduces. Therefore, it is essential to keep traces carrying higher currents as short as possible, to prevent blistering, delamination, or worse – fire.

Isolate Sensitive Components From Heat Source

Electronic components like voltage reference ICs, analog to digital converters, and operational amplifiers are sensitive to temperature fluctuations. Their output can influence when such components get exposed to heat. Therefore these components need to be thermally isolated from the heat sources. You can achieve this by having cutouts in the PCB and providing thermal relief connections such as heatsinks.

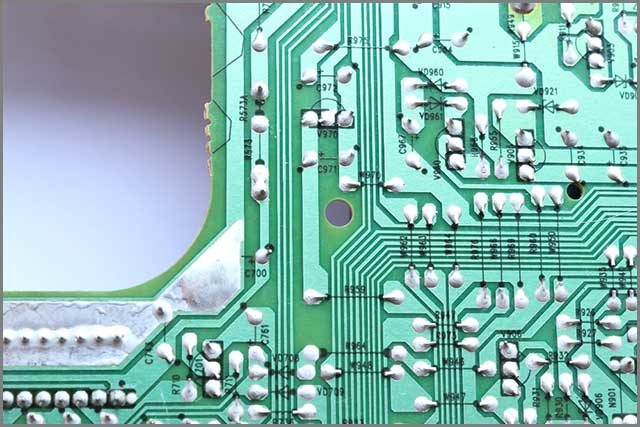

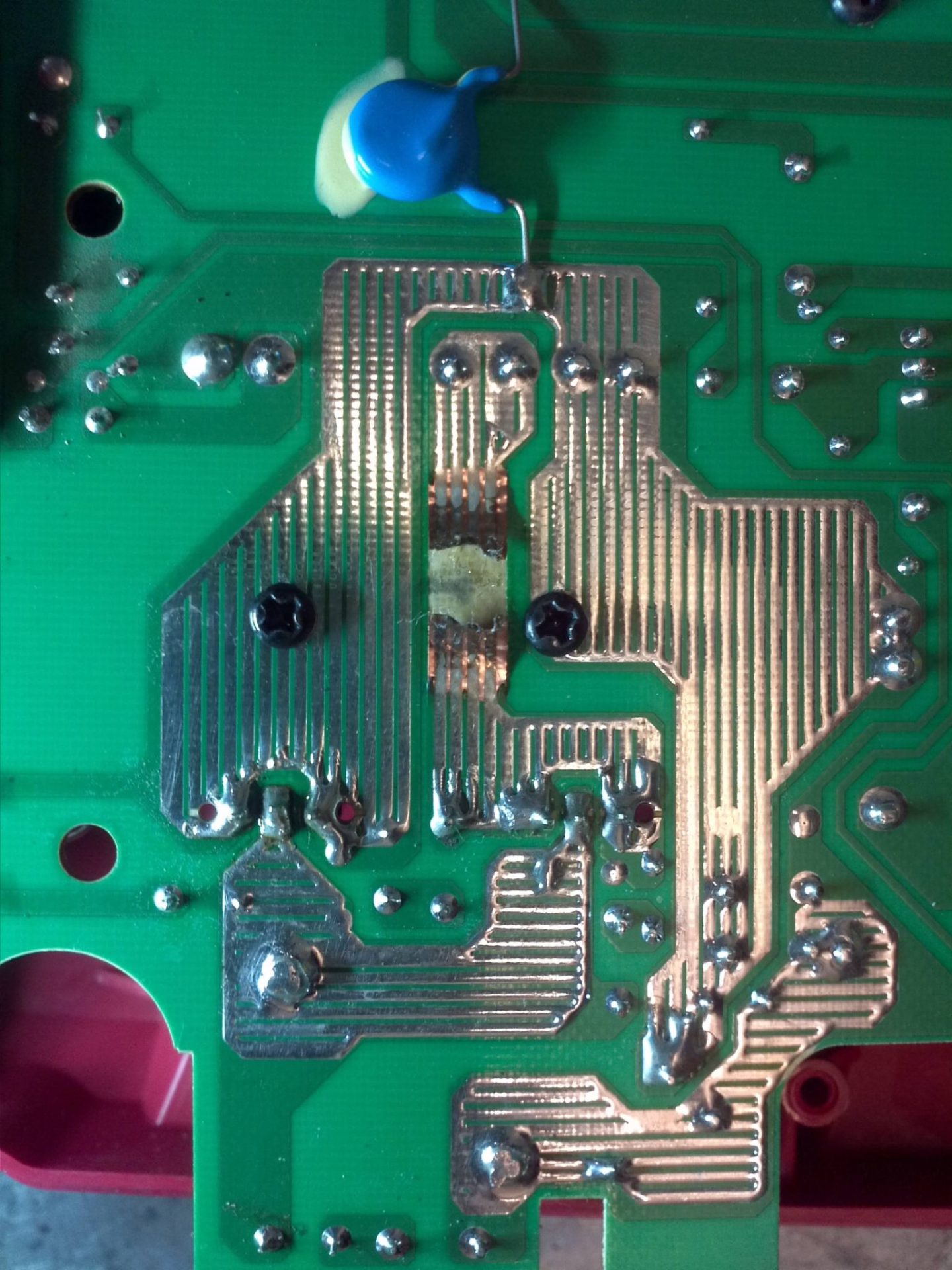

Remove Solder Mask

To increase the current flowing through a trace, you can remove the solder mask, which exposes the bare copper traces. Then you can add an additional solder onto the trace, which will increase its thickness and reduce resistance. This process will allow more current to flow through the traces without increasing trace width or additional copper thickness. This technique is common in power supplies and power amplifier designs.

Use Same Net Tracks on Multiple Layers of the PCB

When there is no room to increase a certain trace width on a single layer, you can route the trace on multiple layers and use vias to stitch the traces in different layers. This process will increase the current-carrying capacity as the total area increases.

Use Internal Layers for High Current Paths

For more sophisticated and compact designs, multi-layer PCBs are more suitable. Multi-layer PCBs offer the benefits of higher board density, reduced size, and enhanced reliability.

In multi-layer PCBs, designers use surface and internal traces differently according to design and performance considerations. You can typically find traces carrying power signals on the surface because of heat ventilation requirements. Higher currents flow through the power signal traces, due to which their temperature rises. Internal PCB layers can trap the heat and lead to the thermal breakdown of power traces. Due to this reason, traces carrying power signals are on the surface layer.

As opposed to the power signals, the traces carrying data signals are on the internal layers. This placement reduces noise and guards against interference. Ambient signals from cell phones, motors, and power lines add up to the signal noise. The exposed external surface of the PCB acts as an antenna and therefore is more susceptible to ambient noise. However, the internal copper layers are guarded against this interference by the external copper layers. For this reason, the traces carrying critical data signals are always on the inner PCB layers.

Considerations While Designing High-Speed PCBs

Trace Length and Spacing

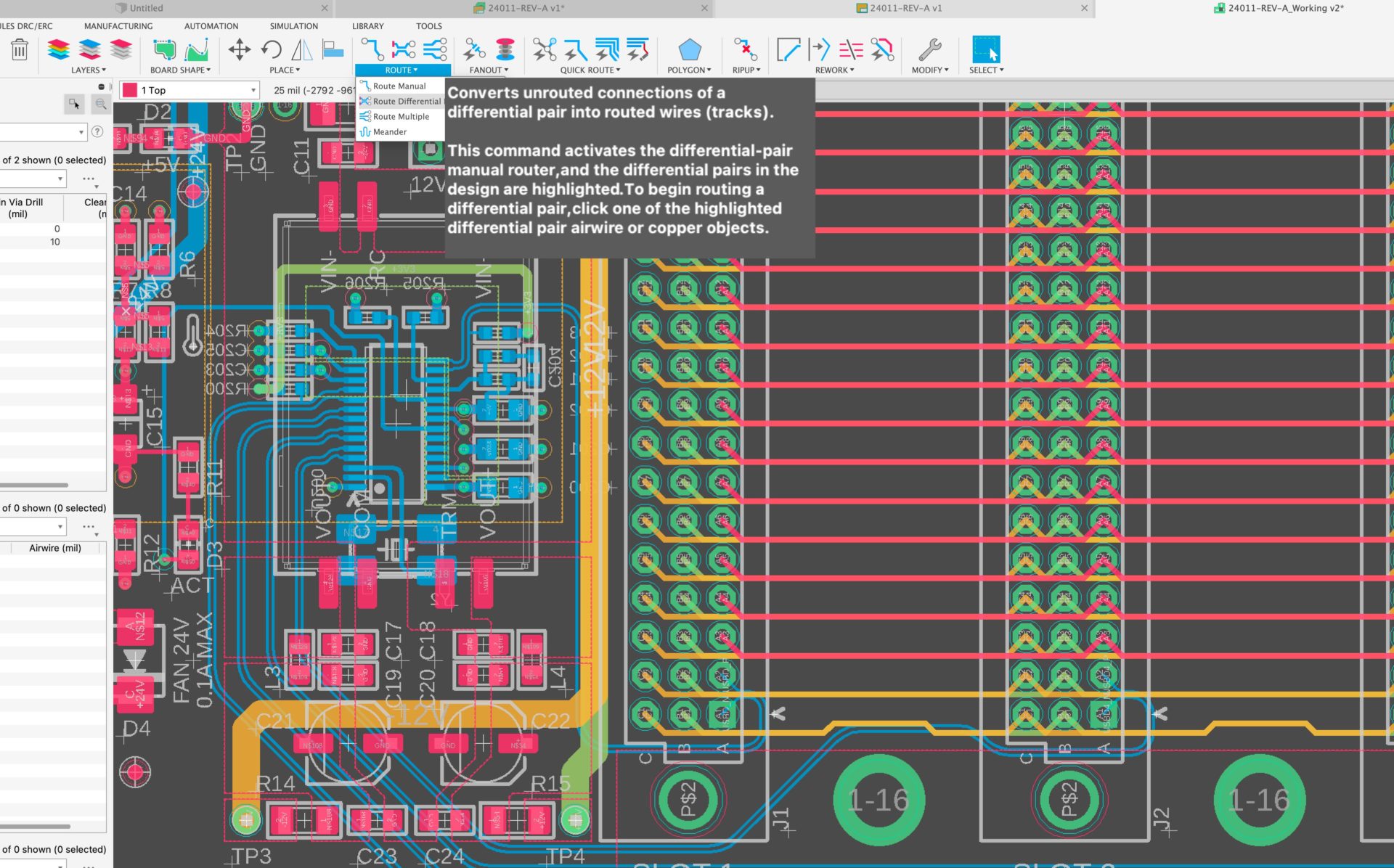

Make sure the lengths of two differential traces match as closely as possible. The tolerance to match a signal and its complement depends on the link’s data rate and rise time requirements. DDR4 signals at 2400MHz clock, for instance, would be length matched to within. The result could be poor communication between devices. A standard specification for differential pair routing is 90 Ohm matched impedance. To achieve this specification, you need to optimize the traces’ width and spacing.

Ground-Filled Traces and Planes:

Circuits that include sensitive components such as wireless chips or antennas may require a little extra protection from external noises. You can minimize the need for additional protection by having embedded ground vias between traces that can significantly reduce coupling, picked up by nearby traces or planes, and off-board signals that creep into the board edge.

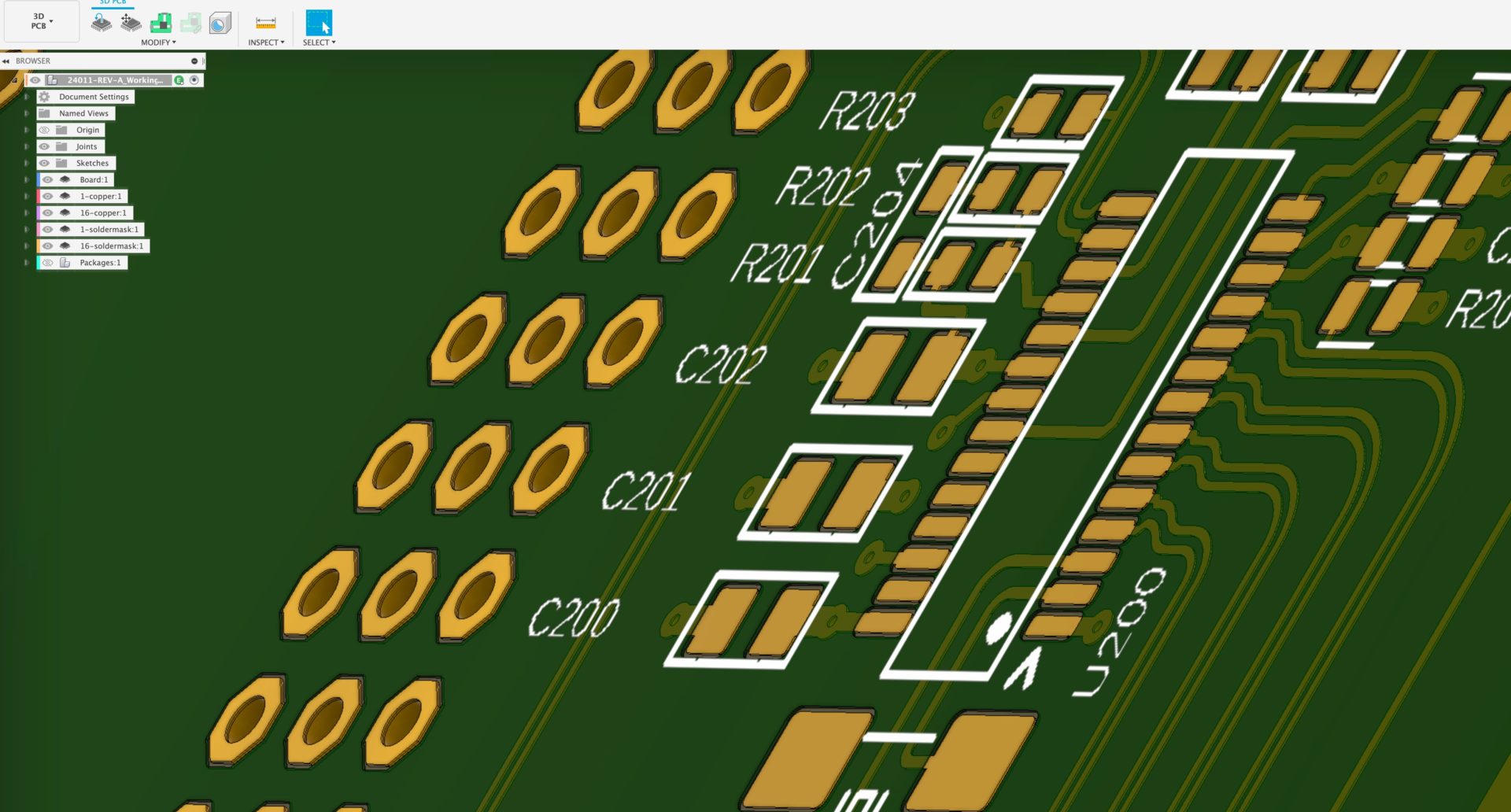

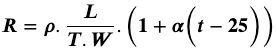

The dimensions and shape of the copper trace on a PCB directly impact the circuit board’s size, cost, and performance. In this context, PCB trace width is of immense importance. Traces meant for delivering power signals need to be wider due to higher current requirements. The PCB trace width is inversely proportional to the trace impedance. The following equation calculates trace impedance:

Where:

ρ = resistivity of copper | α = temperature coefficient of copper | T = trace thickness

W = trace width | L = trace length | t = temperature

Apart from trace width, the shape of the trace has an impact on signal reflection. Asymmetrical trace dimensions and sharp bends give rise to signal reflection, which leads to signal distortion. In multi-layer PCBs, power signal traces are usually placed on the surface layer for improved heat ventilation. On the other hand, data signal traces are placed on the internal layers to guard against EMI and ambient noise.

In high-speed PCBs, reduction of crosstalk and EMI is an important consideration. Due to this reason, these PCBs often employ differential pair signaling instead of single-ended signaling. In differential pair signaling, two traces are used for carrying a single signal. The differential pair signals are 180o out of phase, which cancels out the crosstalk and noise.

Check out this series to learn more:

- High-Speed PCB Design Part 1: How To Identify a High Speed Design

- High-Speed PCB Design Part 2: What to Consider First

- High-Speed PCB Design Part 3: Avoiding Signal Integrity Issues

Fusion 360 Electronics

This article aims to inform you about the importance of selecting appropriate trace widths during PCB designing. Trace width is an essential parameter in PCB design and, therefore, must be chosen after careful calculations and estimations. Novice designers often mistake selecting default trace widths, which sometimes leads to inferior performance and even circuit damage. To learn about how to improve your PCB design workflow with Fusion 360, check out this article.