& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

This post is also available in: Français (French) Italiano (Italian) Deutsch (German)

In this three-part series, we’ll cover three key tools the Fusion 360 Machining Extension brings to the table that will make your process more efficient than ever. Next up is rotary strategy.

Business owners in the manufacturing industry face a plethora of decisions daily. Which new machine should I purchase? How can I produce this part? Who’s going to train our new hire? The Fusion 360 Machining Extension is designed to help you grow your business and hopefully take the decision of which CAD/CAM tool to use off your plate. This three-part series covers three essential tools the Fusion 360 Machining Extension brings to the table. Each tool will save you time, energy, and money. In this article, we’ll dive into Rotary Strategy and how, for those without 5-axis machine budgets or capabilities, this tool can achieve more complexity without the cost of a new machine.

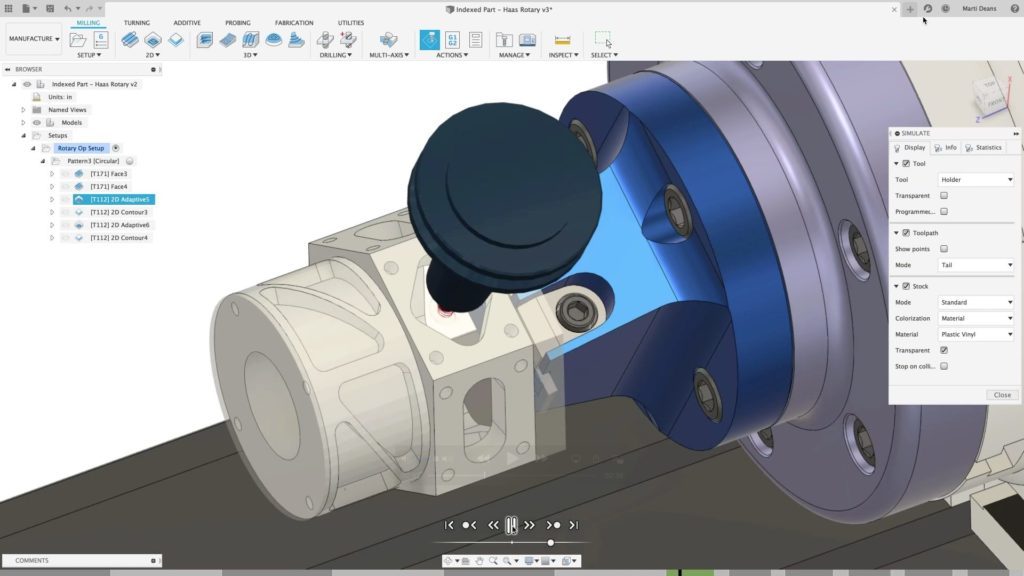

When investing in new machines isn’t in the cards for your business, the next best thing is investing in rotaries for your existing machines. A rotary or 4th axis is a bolt-on piece of equipment that allows you to spin material along (most often) the X-axis so that you can reach multiple sides without repositioning or part flipping your stock material. Rotary Strategy plays a crucial role in honing your process to be as efficient as possible, and it allows you to use tombstone practices to help with batch manufacturing.

The Fusion 360 Machining Extension has built-in Rotary tools that give you access to additional functionality to maximize the efficiency of your machine. As a result, you gain more potential for revenue generation, part production, and batch processes.

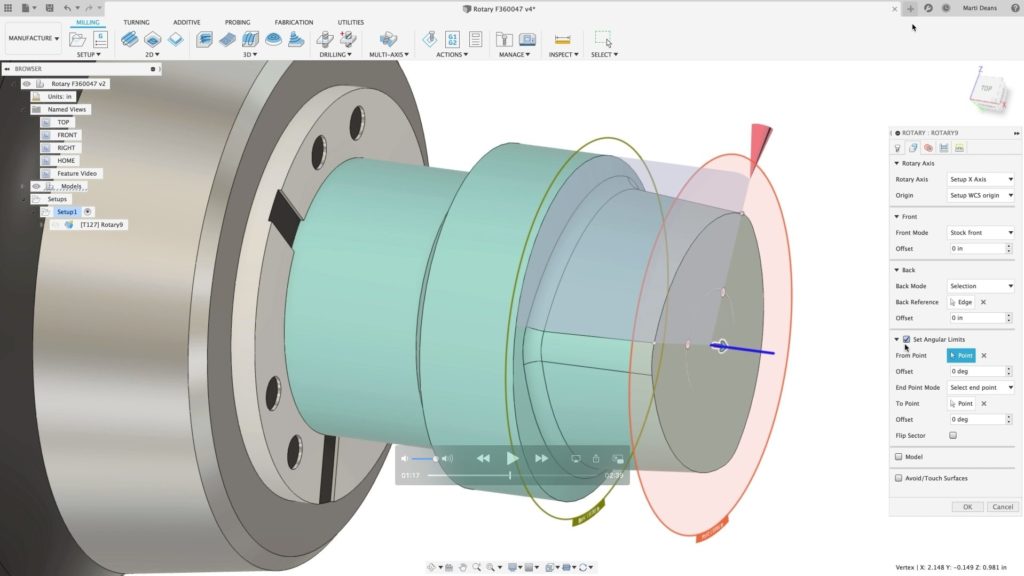

The Rotary tools in the Fusion 360 Machining Extension allow complete 4-axis simultaneous machining of freeform shapes, with multiple pass options to best suit your geometry. They also give you the ability to set angular limits and offset the tool to improve cutting conditions.

The value add here, though, isn’t just in the 4th axis bolt-on rotaries. For folks who have grown past bolt-on rotaries and moved to the big-timers, the Rotary tools in the Fusion 360 Machining Extension are also powerful for multi-axis and turn-mill machines.

Finding a process that works for your business takes time, energy, and money. We get that it can be tough to invest in a new tool you haven’t tried yet. Your ultimate goal is for your workflow to be perfect, repeatable, and profitable, and we believe you shouldn’t have to make concessions to reach your goal. That’s why we offer a free 7-day trial of the Fusion 360 Machining Extension.

If fear of cost, learning curve, or complexity is holding you back, we’re here to support you throughout the process. Access your free Fusion 360 Machining Extension trial to see how much your workflow can change for the better before any commitment. If you could add useful functions to your daily workflow while staying within one platform, why wait? Try it out for yourself today.

Check out Part 1: In-Process Inspection and Part 3: Toolpath Automation of this series for more information.

Want to learn even more about the Fusion 360 Machining Extension? Check out these webinars:

Why Steep and Shallow is a Reason to Upgrade to the Fusion 360 Machining Extension

Why Surface Inspection is a Reason to Upgrade to the Fusion 360 Machining Extension

Why 4th Axis Rotary is a Reason to Upgrade to the Fusion 360 Machining Extension

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.