& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

Felder builds machines for the processing of solid wood, panel material, plastics and aluminium.

This is a generic post processor for Felder F4 Integrate machines.

Please remember to define a Slot Mill cutter to be used as a Saw Blade.

Felder builds machines for the processing of solid wood, panel material, plastics and aluminium.

Felder Hammer is a CNC portal milling machine for woodworking.

This is a sample post processor which allows you the use of any machine for the simulation.

This is a generic milling post processor for NcStudio Programming System.

NcStudio is managed by the Chinese company Weihong.

This is a generic milling post processor for Syntec machines.

This is a turning post processor for Acramatic 850SX control. Use Turret 0 for Positional Turret, Turret 101 for QCTP on X- Post, Turret 102 for QCTP on X+ Post, Turret 103 for Gang Tooling on X- Post, Turret 104 for Gang Tooling on X+ Tool Post.

This is a generic turning post processor for EZ Path conversational. Use tool comment field for tool id value. Use Turret 0 for Positional Turret, Turret 101 for QCTP on X- Post, Turret 102 for QCTP on X+ Post, Turret 103 for Gang Tooling on X- Post, Turret 104 for Gang Tooling on X+ Tool Post.

This is a generic turning post processor for Milltronics. Use Turret 0 for Positional Turret, Turret 101 for QCTP on X- Post, Turret 102 for QCTP on X+ Post, Turret 103 for Gang Tooling on X- Post, Turret 104 for Gang Tooling on X+ Tool Post.

This is a generic turning post processor for OmniTurn. Use Turret 0 for Positional Turret, Turret 101 for QCTP on X- Post, Turret 102 for QCTP on X+ Post, Turret 103 for Gang Tooling on X- Post, Turret 104 for Gang Tooling on X+ Tool Post.

This is a generic lathe post processor for Siemens 840C. Use Turret 0 for Positional Turret, Turret 101 for QCTP on X- Post, Turret 102 for QCTP on X+ Post, Turret 103 for Gang Tooling on X- Post, Turret 104 for Gang Tooling on X+ Tool Post.

Mazak QTU is an innovative Series of CNC turning centers. The Series features a diverse machine selection, including models with rotary tool capability, second spindles and Y-axis capability.

We are happy to support this entire family with all the available controllers: Smooth, Matrix and 640MT.

mazak qtu 200-m, mazak qtu 200-my, mazak qtu 200-ms, mazak qtu 200-msy

mazak qtu 250-m, mazak qtu 250-my, mazak qtu 250-ms, mazak qtu 250-msy

mazak qtu 350-m, mazak qtu 350-my, mazak qtu 350-ms, mazak qtu 350-msy

FlashCut offers dependable, powerful, intuitive and integrated CAD/CAM/CNC software and controls for any CNC cutting application.

This is a generic plasma post processor for FlashCut control.

The following are the new post processors under development, which means they are currently in the testing phase:

If you choose to use one of these post processors, you assume all inherent risk in using it, and we ask that you proceed with caution. That being said, if you feel safe doing so and are willing to test any of them and provide feedback, let us know at cam.posts@autodesk.com.

We are always working to keep post processors up to date with new technologies. This is a summary of the main implementations made to post processors already in the library.

All the post processors have been updated to use the new property definitions. You must have post engine version v4.5702 or higher to use these post processors.

Please refer to the ‘New functionalities’ section for any further clarification.

Datron Next, Datron Next Inspect Surface

All the Datron Next post processors have been updated to properly manage the feedrate output in thread milling cycles.

Haas Next Generation, Haas Next Generation Inspect Surface

Haas Next Generation post processors have been updated. This is a summary of the main modification:

o Drilling cycles support polar interpolation.

o Post processor will no longer output a Z-move when TCP is canceled.

o Post processor will now cancel TCP prior to checking the tool.

o Post processor will now output G94 for a linear move after a multi-axis G93 move.

o Post processor will now turn the coolant on after a stop and optional stop.

o Moves at high feedrate will now be outputted using the correct feedrate mode.

o The work plane is now forced out on operations where the work offset changes.

Makino D300, Makino D500, Makino D200Z, Makino Slim3n

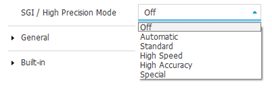

All the Makino post processors have been updated to better handle smoothing logic and codes. Now you can use a brand new ‘SGI/High Precision Mode’ property used to determine new smoothing levels and tolerances:

It allows to properly manage the most appropriate GI function (M250-M255).

The subspindle main operations now are aligned with the main spindle milling operations.

Mazak Integrex i-100, Mazak Integrex i-100s, Mazak Integrex i-200, Mazak Integrex i-200s, Mazak Integrex i-300, Mazak Integrex i-300s, Mazak Integrex i-400, Mazak Integrex i-400s

All the Mazak Integrex i-series have been updated to fix the C-axis positions on the subspindle and to add G17 in linear move to reset plane before G41.

The X-axis is now outputted as a radius value when the Y-axis is enabled.

The Machine Library lets you manage your machine tools by using Machine Configurations to define your available machines and resources. These configurations can automate the settings in your Job Setup.

There are many Machine Configurations available in the standard library.

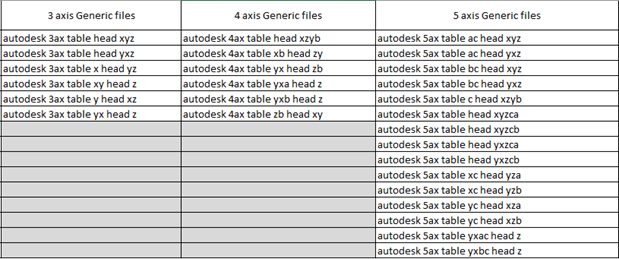

In the library you will find many Autodesk generic simulation files for most of 3, 4 and 5 axis milling machine kinematics:

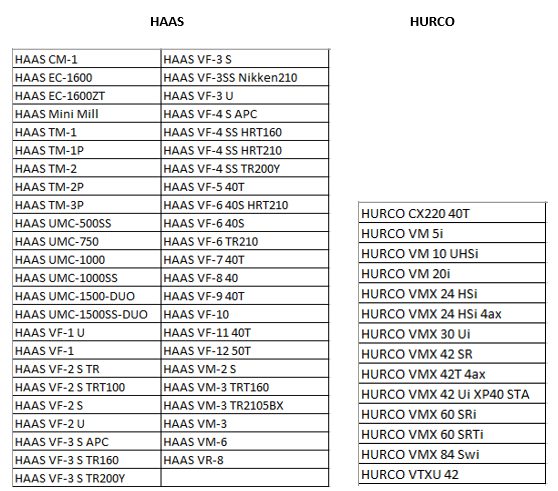

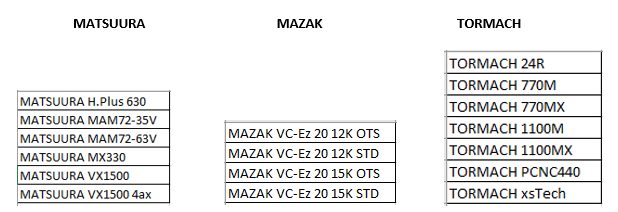

In addition, you will have available configuration files for some of the leading machine manufacturers:

The easiest way to get started, is to copy an existing configuration that matches some of the characteristics of your machine.

Any additive machine configuration file has the relevant post processor associated.

Choosing a new additive machine configuration file, the related post processor will automatically be selected.

The Post Processor Training Guide has been updated in the following sections to reflect the new multi-axis features:

Paragraph 4.3.5 Work Plane – 3+2 Operations

Chapter 7 Multi-Axis Post processors

Please remember you can find here the Post Processor Training Guide.

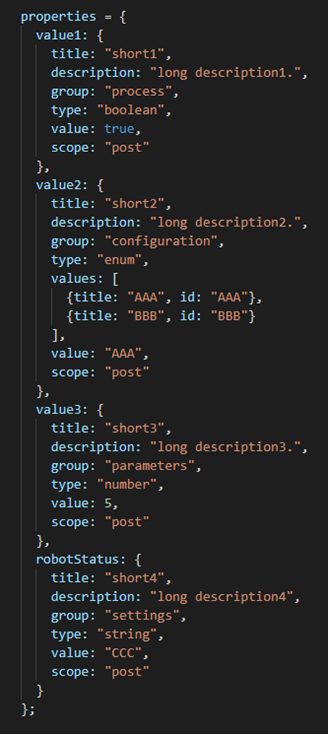

Since Post Engine v4.5702, a unified post properties definition has been introduced, which allows to define the properties and property definitions in one place.

Here is an example of the new format:

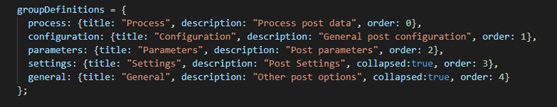

The extra information of each group can be given through a groupDefinitions (optional).

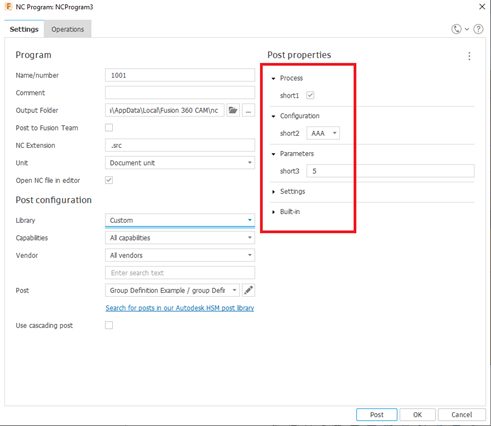

This is the groupDefinitions outcome in the NC Program UI:

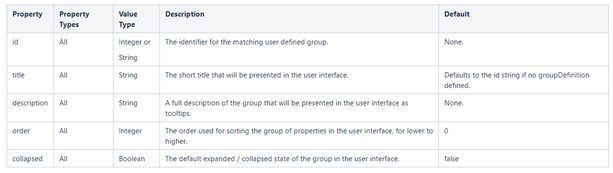

The following properties are supported for the groupDefinitions:

We provide a new global function getProperty() to access the value of each property:

getProperty(properties.propertyId);

// Pass by property object, the current state of the property value will be returned

getProperty(“propertyId”);

// Pass by property’s id (in string), the current state of the property value will be returned

getProperty(properties.propertyId, sectionId);

// Pass by property object, the property value of the specified section will be returned.

getProperty(“propertyId”, sectionId);

// Pass by property’s id (in string), the property value of the specified section will be returned.

The new setProperty function has been added at the end of each post processor

function setProperty(property, value) {

properties[property].current = value;

}

To achieve the machine simulation some minor post processor updates are needed.

This AKN article outlines the reason for the change and also explain the needed modifications.

We suggest you using the machinesimulation.cps post processor as a sample for the configuration. This other AKN Article describes how to use the generic machine simulation post processor.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.