& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

This post is also available in: Italiano (Italian) Deutsch (German) 日本語 (Japanese)

The Mortensen Center in Global Engineering is working towards access to fresh drinking water in remote communities using Autodesk Fusion 360.

It’s one thing to install a water well hand pump and provide much-needed access to fresh drinking water in a remote community. It’s quite another to know how long it will last and if it’s working months or years after installation. The Mortensen Center in Global Engineering (MCGE) at University of Colorado, Boulder decided to investigate and provide more visibility for this common challenge, among its many other research projects and innovative educational program.

MCGE combines education, research, and partnerships with organizations like the Autodesk Foundation to positively impact vulnerable people. And it’s all with the vision for everyone in the world to have safe water, sanitation, energy, food, shelter, and infrastructure. MCGE provides students the unique opportunity to become global engineers by learning policy, fieldwork, and many pressing topics, including disaster resiliency and post-disaster construction; water, sanitation, and hygiene (WASH); and system theory for development.

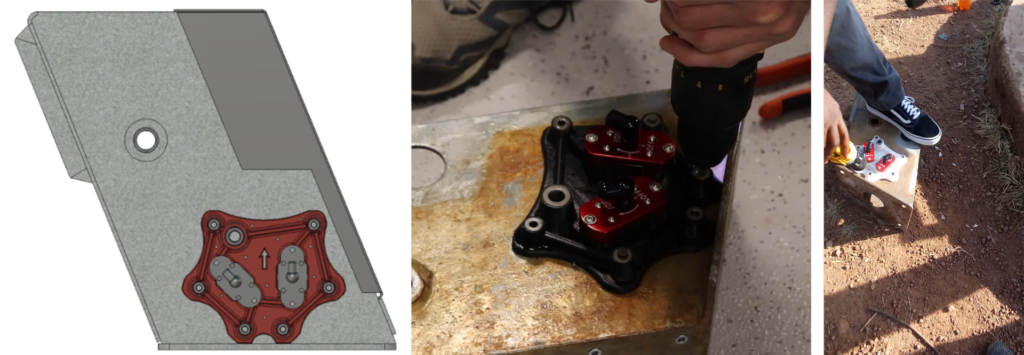

Ph.D. student Taylor Sharpe is a researcher and instructor who manages the lab at MCGE. He and his team took on the challenge of designing sensors for installation on drinking water pumps in Nigeria. These sensors could provide revealing data on pump failures by counting the number of times the handle is used and when, measuring current to electrical boreholes, and measuring water levels in raised cisterns. The team had to consider many factors, such as size, durability, clearance, and ease of installation.

Sharpe has used Fusion 360 for product design and research projects since the end of his undergraduate year for a mechanical engineering degree. He has worked on an air-quality measurement tool for use in Rwanda, latrine occupancy monitors in Kenya, water level monitoring systems in Sierra Leone, and more.

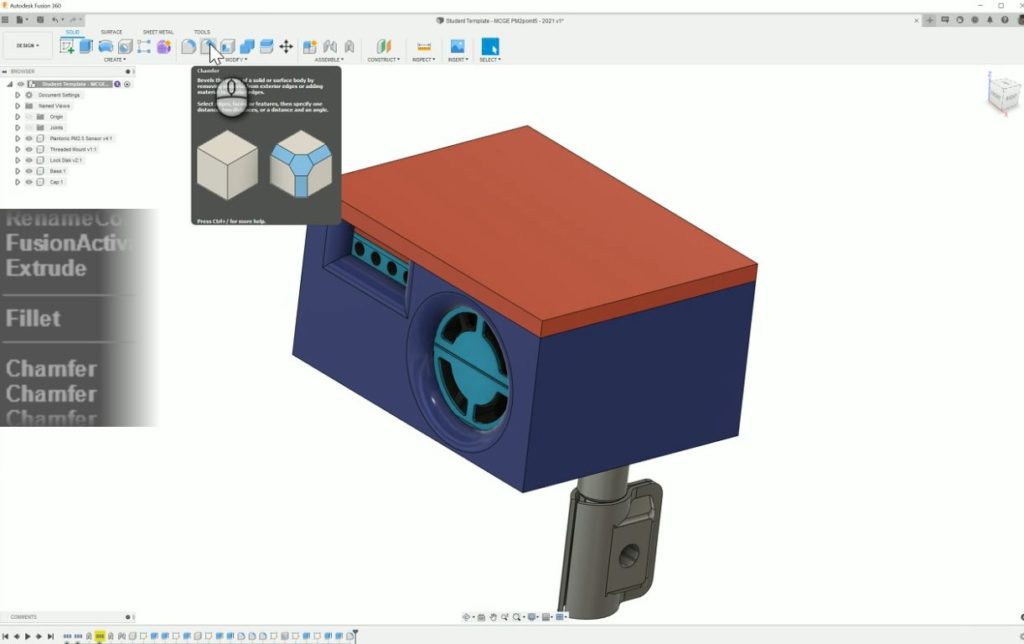

Fusion 360 was the centerpiece for all development and collaboration for the hand-pump sensor project. The team was global, working between Colorado, California, Kenya, and Nigeria. Due to the pandemic, Sharpe and the team had to abandon their usual site visits. Instead, they solely relied on Fusion 360 to bring the sensor to life through 3D models.

“Our goal with the hand-pump project is to provide the insights for the support of sustainable water services.”

—Taylor Sharpe, PhD student, Mortensen Center in Global Engineering

The team faced another major challenge—how to communicate sensor installation within the pumps and instruct where to drill. Training materials were easily developed and viewed within Fusion 360, including renders produced for videos and written documentation.

On the ground in Nigeria, they also discovered another hand pump model was unexpectedly prevalent. They were able to update the design to fit a new, unexpected geometry, using a patchwork of communication technologies to work together with co-designers on the ground. One of these technologies was Fusion 360.

Two hundred sensors were installed on handpumps, electrical boreholes, and water cisterns to transmit the data via satellite for monitoring. The resulting insights help create a broader and well-documented account of performance and required maintenance. This is especially important for remote areas. Without cell service to report a broken pump, remote areas can lose access to clean water for stretches of time.

“A handpump on its own is not a long-term sustainable solution,” Sharpe says. “This type of monitoring and data collection is important to drive awareness of policy changes needed for infrastructure funding and water management.”

“The smooth integration of electrical and mechanical, machining capabilities, and the collaboration features really differentiate Fusion 360 from any other software packages. That’s why it’s always my main choice now.”

—Taylor Sharpe, PhD student, Mortensen Center for Global Engineering

MCGE provides engineering students with exposure to global development issues through research projects and classes. The center also inspires careers that bring about sustainable solutions.

Each semester, Sharpe leads a class for graduate students to learn about mechanical design. Most of the participating students are environmental engineering or civil engineering majors. A hands-on lab provides them with their first taste of product development and mechanical engineering.

Thanks to the Autodesk Technology Impact Program, every student is provided their own copy of Fusion 360 to tweak, design, and prototype a monitoring system. It’s an eye-opening experience for many.

“At CU, you can leave with a Global Engineering certificate,” Sharpe explains. “Fusion 360 has been an integral tool to the student experience at CU within the Global Engineering Program. For example, students have been able to use it to learn how instrumentation monitoring works and to understand key intersections of engineering and public health. It’s all part of the exploration and exposure to help them go out and solve our biggest problems.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.