& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

This post is also available in: Italiano (Italian) Deutsch (German) 日本語 (Japanese)

See how Autodesk Fusion 360 helps Next Intent up-level employees and gain confidence when manufacturing high-risk parts for the aerospace industry.

A machinist isn’t just a machinist anymore. That’s the view Rodney Babcock, CEO and founder of Next Intent, has after more than 25 years running his machine shop. With Autodesk Fusion 360, machinists can begin learning how to program machines the minute they step in the door, and the learning curve is low for current employees. According to Babcock, there are quite a few reasons why that’s so important.

In the era of the “Great Resignation” and labor shortages, it’s a strategic advantage to have back-up for the more experienced programmers. Fusion 360 enables machinists at all levels to easily check models and dimensions on model-based or limited dimension drawings. If there’s only a small fix required, it can be solved right away. And as machinists build their Fusion 360 skills, they can also start taking on their own projects.

“I think it also helps with employee retention and attracting new employees,” Babcock says. “When you show up to work here, we’re going to give you a copy of Fusion 360 and a laptop, and you’re going to start learning how to program. Plus, the interface is easy to use and there are so many tutorials, courses, and resources online that makes it easy to get started,” he continues. “Now, we’re using Fusion 360 on a daily basis on the shop floor.”

“If my primary programmer is two weeks into a complex program, do I really want to interrupt him to get a bolt-hole pattern for a fixture or a second operation on something we determined out on the shop floor? Now, he doesn’t get bothered and has the time to stay focused on the complex part. We can pick up the ball and run with it — and keep things rolling with Fusion 360.”

– Rodney Babcock, CEO and Founder, Next Intent

Next Intent’s customers and projects are primarily in the aerospace, defense and space industries, from titanium springs that mitigate vibration from rockets to parts for the Mars Rover and James Webb Space Telescope. Among their many projects, they will soon begin work on the camera body assemblies for the Giant Magellan Telescope, which will be the largest optical telescope in the world when completed.

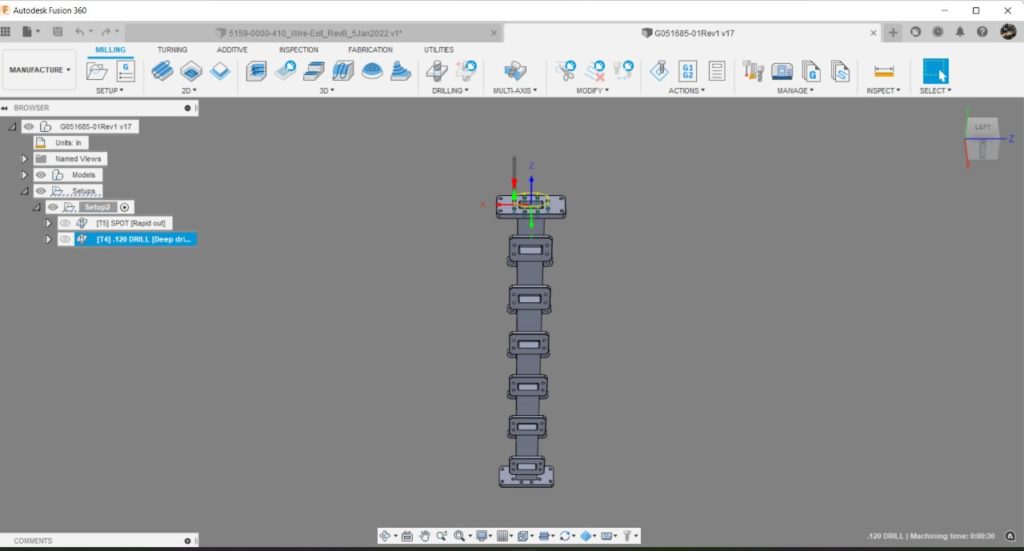

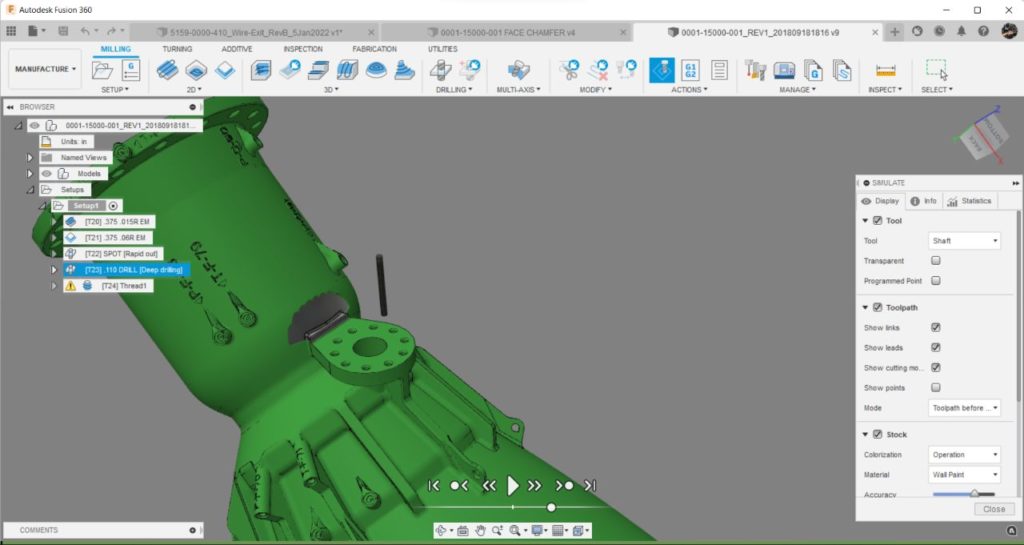

Jesse Hesch, a long-time machinist and programmer at Next Intent, used Fusion 360 for a recent jet engine/nozzle project—and there was zero margin for error.

“There were no spares, and each part took a month to 3D print in Inconel,” Hesch says. “The risk was a super nail-biting experience. If one tap breaks or I mill a surface too deep, then we would have to wait a whole month for them to print it, ship it to us, set it up, mill it, ship it back. The reliability of Fusion 360 and being able to generate the tool path with confidence was so important.”

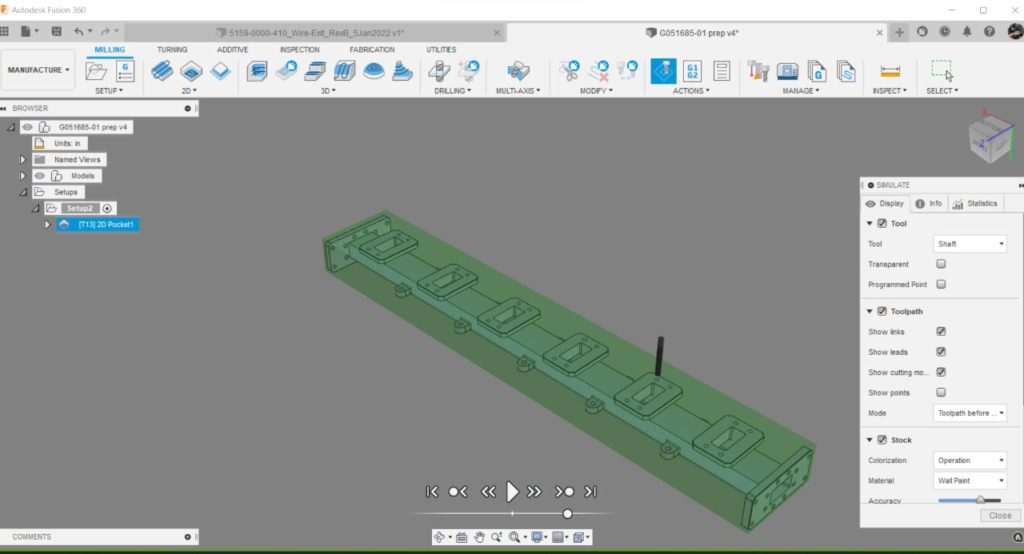

Another titanium part project looked seemingly simple with its rectangular shape. But Hesch explains there was much more to it because machining an additive manufactured titanium part can be fickle. Even though it was a simple operation, all the parts were high risk.

“Importing the model and being able to visualize my own plan of attack was really helpful for me,” Hesch says. “I didn’t have to try and figure out why someone else programmed it the way they did. With Fusion 360, I had the ability to take on the project, manipulate it, and edit it as I went. I could just tackle the part and not have to wait for our primary programmer. You have the adaptability to get the job done.”

As the Next Intent team’s expertise and types of projects using Fusion 360 expand, Babcock is confident with the performance and results. This confidence is especially important when materials for a single part can be in the tens of thousands of dollars.

“We’ve found Fusion 360 to be very solid and it generates really good G-code,” Babcock says. “Fusion 360 works well across multiple platforms. We have mostly Fanuc-controlled machine tools, and we use it all the time. Every day of the week we’re using Fusion 360.”

Do you want to upskill your employees and feel confident in your CAM software when manufacturing high-risk parts? Try Fusion 360 for free today:

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.