& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

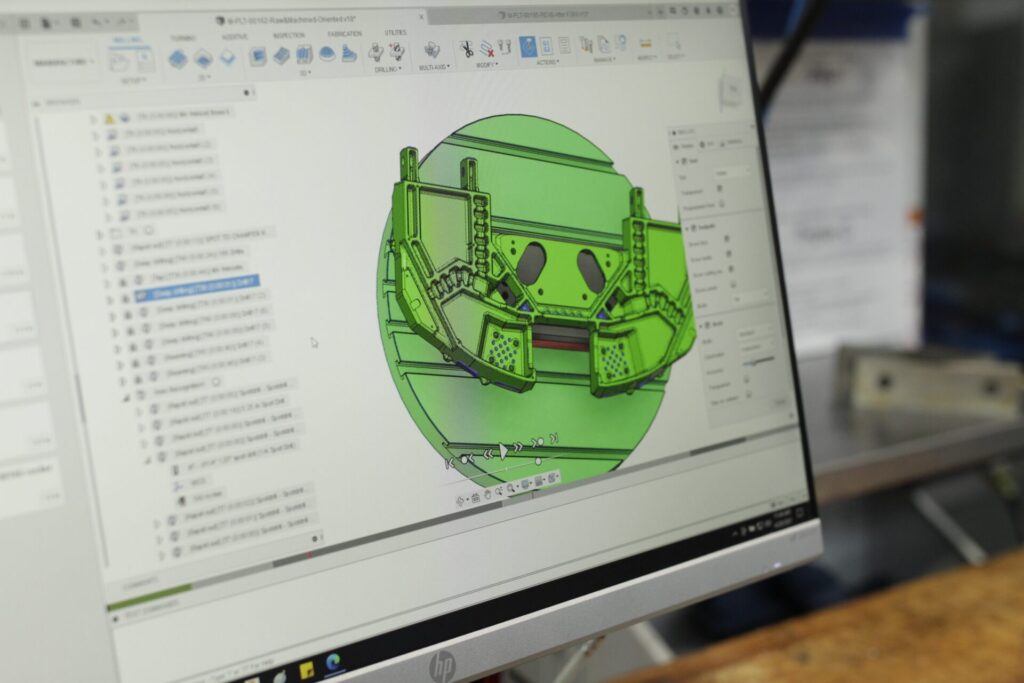

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

7 min read

This post is also available in: 日本語 (Japanese)

Learn about the benefits of computer-aided design (CAD) technology, the industries where it’s utilized, and emerging trends in the area.

Computer-Aided Design (CAD) is the use of computer technology to aid in the design and drafting of a practical product or artistic creation. CAD technologies are software programs specifically created for this purpose.

CAD technology offers numerous benefits and has become widely used by professionals in various fields, from artists to automobile designers, civil engineers, architects, and more. CAD technologies can help teams:

The market for CAD technology has expanded significantly in recent decades as more organizations have recognized its advantages. In 2005, the size of the CAD software market was approximately $5 billion, and by 2019, the market was valued at $9.3 billion.

This growth trend is expected to continue, with the market projected to reach $18.7 billion by 2030. Here, we will explain this popularity by discussing how different industries use CAD software and how it continually changes how businesses operate.

Because of its versatility, CAD technology has many applications and is often utilized differently depending on the professional. The best way to incorporate CAD technology into your job will vary depending on your industry.

By examining how different industries use CAD software, you can better understand its functions and discover how to maximize its potential benefits. Five major industries utilize CAD technology the most in their essential operations:

In the digital age, CAD technology has become a popular tool for graphic designers. With the help of CAD software, graphic designers can develop more detailed mockups, create unique shapes and typography, and add a wider range of visual effects (animations, backgrounds, etc.) to their designs.

Teams of graphic designers can use CAD technology to communicate with each other more efficiently when implementing edits and sharing ideas for projects.

Additionally, CAD software can help graphic designers work faster by allowing them to apply edits to their work in real-time, without the need to create an entirely new paper mockup for each version of the design. With this technology, design firms and freelancers have increased their profit margins by:

CAD technology serves a range of important purposes in architecture. Modern architects and architectural drafters use specialized CAD software to:

CAD technology creates a digital image of the blueprint for architects to work on, rather than a paper sketch on a drawing board. Working with these digital images allows architects to more easily:

Functions like CAD blocks can save architects time and energy by eliminating the need to redraw common components every time they appear.

CAD software can also help architects draw complete blueprints in less time, assess potential risks, provide more accurate budget estimates, and meet project deadlines. Ultimately, using this technology can result in safer buildings, fewer accidents, less waste, and lower costs for construction projects.

CAD technology has permanently reshaped the engineering industry in various ways. Modern engineers use CAD systems throughout the design and testing processes. These programs can improve operational efficiency and help engineering teams analyze their designs more accurately.

Compared to paper drafting, CAD technology makes it simpler for engineers to determine the ideal specifications for each design component, such as the component’s dimensions and its intended location.

CAD software also makes editing designs easier and less wasteful by allowing one to change the specifications of individual components without replacing the entire plan.

In addition to the design process, CAD technology has also significantly improved how engineers test what they build through interactive stress tests and simulating the function of their designs before manufacturing. For example, a team designing an engine can use CAD technology to simulate the motion of the pistons or the flow of coolant to the radiator.

The use of CAD technology in engineering can help companies:

Computer-aided design technology is also used heavily in the design and development of video games. Modern consumers have high standards for their video games, and CAD helps game companies create better quality content in several ways.

CAD software features like painting tools and material editors allow designers to customize the shading and texturing in their games with greater detail, helping them to appease the discerning tastes of fans.

Game designers can also use CAD software programs to:

By using CAD software, video game developers can achieve a higher degree of visual customization, complete tasks more efficiently, and design better gameplay. Ultimately, using CAD technology in game design has streamlined the production process and resulted in more immersive, higher-quality games for consumers.

While Computer-aided design technology is commonly associated with design, companies in many industries also use it to streamline and guide their manufacturing processes. Manufacturers can design and edit their prototypes with the production process in mind, helping them ensure efficiency and sustainability.

There are also some programs designed specifically for manufacturing. These programs, known as CAM (computer-aided manufacturing) software, can help manufacturers:

CAD technology gives manufacturers across various industries the tools to design better prototypes, improve production efficiency, enforce compliance, and enhance oversight. These benefits enable them to expand their profit margins and increase product quality.

Computer-aided design technology is constantly changing and evolving, just like business needs. This evolution will continue as technology advances further. Several notable CAD technology trends have recently emerged:

Many industries, such as healthcare, finance and entertainment, also use artificial intelligence (AI). Computer-aided design technology paired with AI can automate functions, optimize design models, and reduce task completion time.

Healthcare professionals can use AI-powered CAD solutions to detect and diagnose diseases, predict patient outcomes based on data, and interpret medical imaging (X-rays, CT scans, etc.) with greater accuracy.

Engineers and manufacturers can use AI computer-aided design software to integrate data from different processes to achieve optimal efficiency and proactively identify flaws in their product design or manufacturing methods.

Game designers can use AI CAD to make decisions regarding game layout and the connections between individual components. CAD helps ensure that elements complement each other and adhere to fundamental design rules (alignment, balance, emphasis, etc.)

Model-Based Definitioning is the practice of using 3D models to document product information during the initial design process. Due to its various benefits, it has become a popular way for manufacturers across industries to record product information, such as design intent and geometric dimensions.

Computer-aided design with model-based definitioning can help businesses unify their design and manufacturing processes. CAD also makes it easier to conduct quality assurance. By consolidating data from both processes, businesses can improve manufacturing efficiency and reduce automation costs.

Model-based definitions can also save time and reduce waste. They eliminate the need for traditional paper drafting and 2D representations.

The American Society of Mechanical Engineers in ASME Y14.41 defines the standards for digital production definition data. Standards include rules for using GD&T and other requirements for production definition.

Another prominent computer-aided design trend is the growing use of software for 3D printing. The 3D printing market has expanded significantly in recent years and will continue to grow. As this occurs, more people and businesses will begin utilizing CAD software to design parts for 3D printing.

Commonly used in the aerospace and automotive industries to produce affordable, lightweight parts, 3D printing has a wide range of applications. Compared to more traditional manufacturing methods, 3D printing makes it easier to design and produce prototypes and components with complex designs.

Computer-aided design software automatically relays critical design information (dimensions, weight, materials of components) to the 3D printer. In addition to the obvious time-saving benefits, this can help designers avoid mistakes and ensure that the final product meets their exact specifications.

While it offers some distinct advantages, 3D may not be the optimal design method for you. When selecting a medium for your design, it’s critical to carefully consider your needs and objectives before making a final decision.

Ready to see how computer-aided design can transform how your team collaborates and brings products to life? Try Autodesk Fusion 360 for free today.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.