Generative design in Fusion 360 goes beyond running studies. Explore how to easily edit parts, run simulations, and more.

There’s nothing quite like the satisfying feeling of optimizing a design for performance and manufacturability with generative design. However, in all the excitement of creating a new study, it can be easy to forget how flexible and dynamic the tool actually is.

Like any other tool, it’s up to you to best apply generative design to your workflow. If you’re looking to take your workflow to the next level, here are some things you may not know the tool can do:

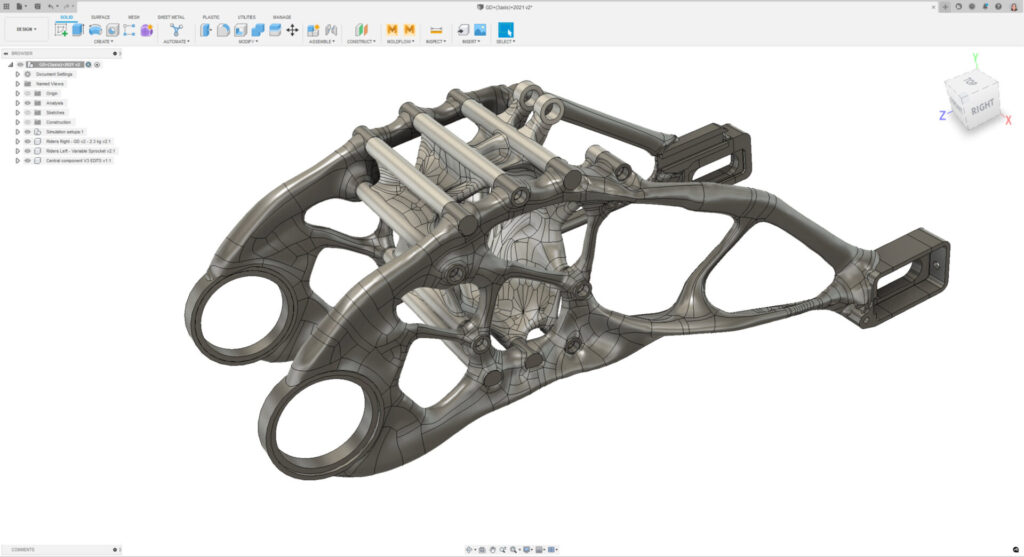

Easily edit your generative design parts

Next time you produce a study, know that you still have options. A converged study doesn’t have to mean the end of your process. Sometimes you want to use a generatively designed part as is, and sometimes, it doesn’t meet your desired aesthetic language. Maybe you want to add some symmetry, smooth out some surface tension, or use the part geometry as a basis for something entirely new built by hand. All of these options are legitimate and possible.

When you download and open a generative part in Fusion 360, it comes with a timeline pre-populated with features used to reconstruct the design. You can edit these features to modify the part as you see fit.

Remember that what the generative design tool initially produces is the most optimized form for your mechanical specifications. If you change the part, you will also change its performance. That’s where simulation comes in.

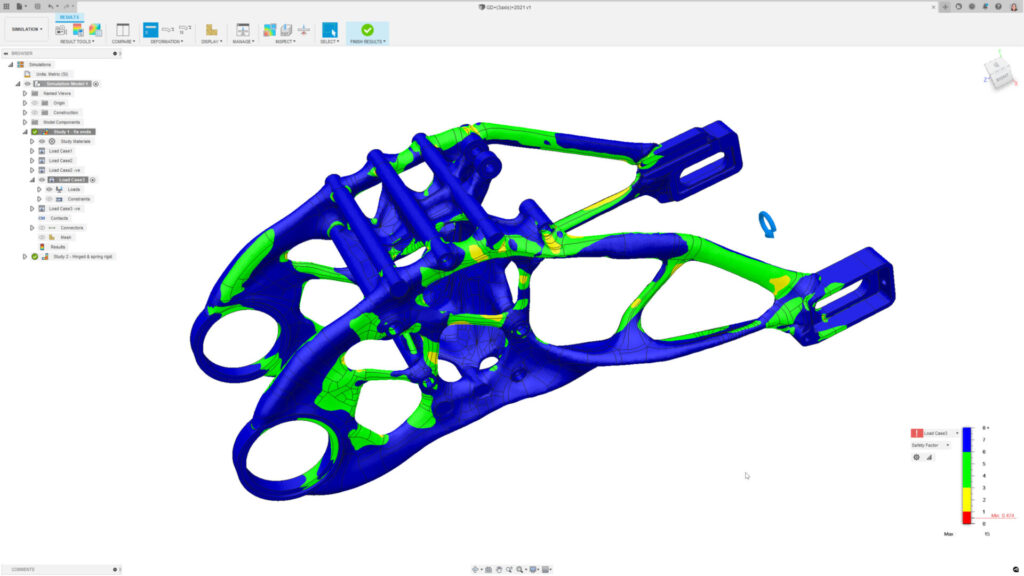

Check part performance in the Fusion 360 Simulation Workspace

Did you know that generatively designed parts carry over their study data? It’s true! When you switch to the Simulation Workspace, a prompt will appear asking if you’d like to use your part’s study data for simulation setups.

Simulation results will give you a wealth of detailed information about how your design performs under all the loading conditions it will be under. Results can also be a valuable validation tool, just as if you’d made a CAD model yourself.

Generative design studies are pre-populated with the loading information you used to create your setup, letting you run a simulation study with the click of a button.

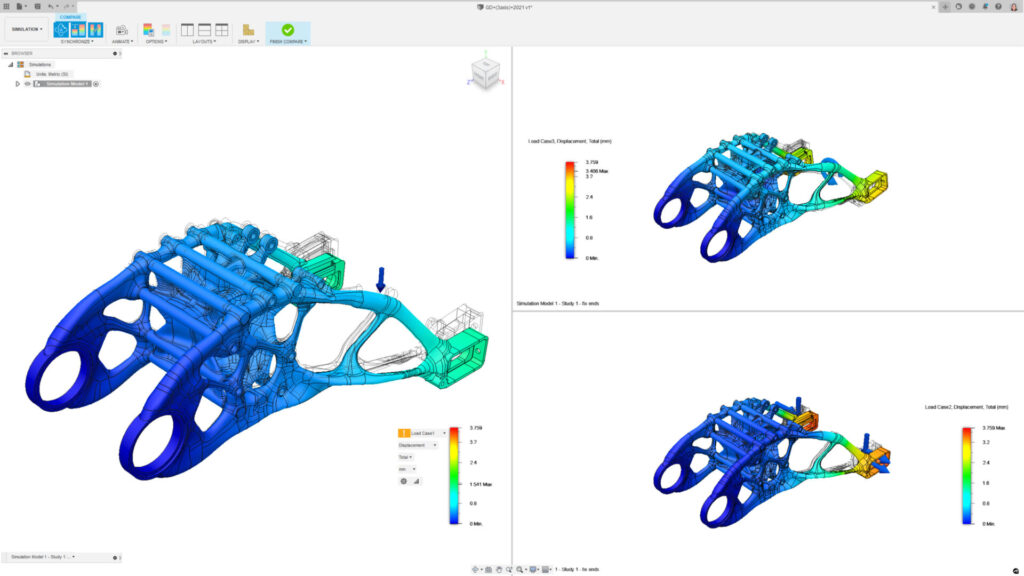

Simulation can also be a great way to consider physical requirements that are impossible to set up as objectives for generative design, such as thermal stresses or dynamic loads. You can think about generative design as an intelligent CAD modeler that creates a highly efficient shape that might be 95% of the way to your final design. You can then use a combination of simulation, and the highly editable generative design outcome, to fine-tune our results and account for specific part performance requirements or to put our own aesthetic stamp on the final shape.

This ability is convenient when continuing to work on generatively designed parts as you can check their performance and make changes.

Run an event simulation to test your part “IRL”

Generative Design is an incredibly powerful tool for refining your part to its idealized geometry, specifically for linear static stress conditions. However, that doesn’t necessarily answer all the questions you might have. You may need to answer additional questions about how your part performs. For example, you can also run an event simulation to see how your part will perform under a specific condition. One of the most common conditions to test is an impact collision.

This is just the beginning, though. Generatively designed parts can also test for thermal stress (e.g. is heat transferring through your assembly now that you’ve introduced a generatively designed part?). You can also put parts back into an assembly.

Use generative design when you want it, how you want it

These are just a few tips for incorporating generative design into your workflow in new ways. Our best advice? Experiment! Try using a mix of generative design and traditional modeling to produce foundational geometry to work from. Or even remix your study by introducing a solved part. The generative design world is your oyster.

Interested in giving these tips a try in Fusion 360? Download a free trial today.