& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

This post is also available in: Italiano (Italian) Deutsch (German)

Explore how the aftermarket automotive industry fits into the larger automotive industry landscape and what makes aftermarket parts unique.

Anyone who owns a vehicle or completes regular maintenance and upgrades on a car has likely purchased an aftermarket product, whether they knew it or not.

Some automotive manufacturers design universal parts that fit every vehicle. However, each automotive giant designs its vehicles differently from year to year. Vehicle owners will often have the same make and model that varies depending on trim, transmission, or body style.

So, where does the aftermarket automotive industry fit into the automotive industry landscape? What makes aftermarket parts unique?

The aftermarket automotive industry is a secondary market within the automotive industry. It includes product offerings like replacement sensors, performance upgrades, and various compatible accessories, among many other parts. It’s an industry that manufactures, distributes, retails, and sometimes assists in installing its products.

There are many reasons why aftermarket products exist. To name just a few:

Original equipment manufacturers (OEMs) charge a premium for factory parts. The automotive aftermarket is an affordable alternative for do-it-yourself consumers. You can purchase the same part for a reduced price from a non-OEM manufacturer.

For example, in the last ten years, LED headlights have become increasingly prevalent on the road. This is because consumers can purchase aftermarket products from overseas at extremely reduced prices. A set of LED lights from a reputable manufacturer could cost over one hundred dollars, whereas an overseas company can manufacture LEDs with exact/universal specifications and sell them on eBay for around forty dollars.

If all that existed were OEM parts, consumers would be stuck buying directly from their car’s manufacturer, leaving them with only one (possibly expensive) option. With a large selection of products, consumers can choose what is best for their unique situation.

Of course, many car enthusiasts seek out expensive, top-quality parts for their vehicles. But that’s the beauty of the aftermarket industry — there are parts available at all price points.

Another reason the aftermarket automotive industry thrives is thanks to vintage vehicles. Vintage car connoisseurs often want to keep their cars pristine but run into challenges when parts get discontinued or are no longer up to modern standards. Many aftermarket automotive companies focus on designing modern parts for vintage cars, often specializing in a particular vehicle make. BBI Autosport, for example, focuses on Porsche vehicles, designing parts for racing and for everyday driving.

Aftermarket automotive shops are typically smaller than industry giants in the automotive space. Thus, they’re usually more agile in their workflows. Working with speed and flexibility enables aftermarket automotive companies to experiment with many solutions without the barriers that corporate environments face. Not to mention many people who work at aftermarket automotive companies are pure automotive enthusiasts with strong backgrounds in the automotive industry. So if you’re looking for a solution that your vehicle’s manufacturer hasn’t released yet, there’s a good chance a grassroots aftermarket automotive shop has dreamed up and released a comparable solution.

The aftermarket industry is important to consumers and retailers because it helps balance the market, drive costs down, foster innovation, and employ designers and engineers.

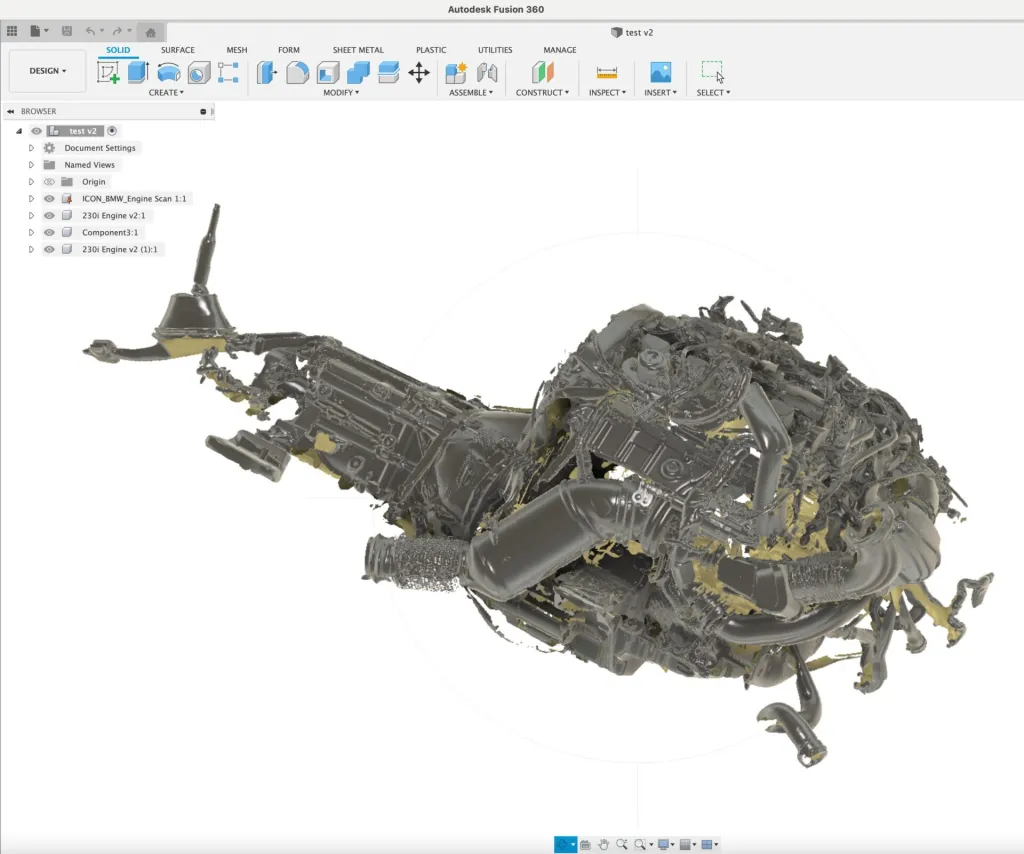

Anyone designing aftermarket parts must be extra careful to ensure they meet quality standards, especially those manufactured to fit a specific vehicle. Many designers and engineers in the automotive space use CAD and CAM software to accurately 3D model parts. An integrated CAD/CAM software like Autodesk Fusion 360 enables you to create 3D models of OEM parts and easily prepare them for manufacture.

One common workflow in the aftermarket space is scan to CAD. You can either scan an OEM car part and then adjust the 3D model as needed. Or, you can scan an area of the car to capture the exact dimensions needed for any new parts you create. This process helps you get an accurate part ahead of manufacturing.

Whether you run your own aftermarket automotive shop or are looking to experiment with designing your own custom parts at home, Fusion 360 is an excellent tool. Download Fusion 360 today to create affordable and functional parts for any vehicle.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.