& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

Product development firm Brownlie Design has a client roster that includes household names like Bosch Tools, Caterpillar, Fisher-Price, Toyota, and Under Armour. A typical day for the 12-person shop, located in the Finger Lakes region of upstate New York, sees the Brownlie team developing design concepts across a vast range of product types.

Recently I had a chance to talk with Brownlie industrial designer Mike Kowalski about the firm’s approach to rapid iterative design—and how Fusion 360 helps accelerate that approach.

At the beginning of a design process, Kowalski and his colleagues must work through many potential options to zero in on the concepts that will work best to solve the challenges posed by a particular project. Often this begins as sketches on paper and in Photoshop, and, depending on the project, may lead to initial models sculpted in the shop. The goal is to see how the initial concepts laid down on a page will begin to take shape in three dimensions. Using Fusion 360 from the outset of a project has enabled Brownlie Design to simplify the process, and allowed them to uncover many opportunities to improve designs even before they reach the stage of physical prototyping.

Fusion 360 also allows the team to share these 3D designs with clients early in the process. Through a simple URL, the client can view and rotate the design to see it from all angles—a much different experience from looking at flat images in a PowerPoint deck.

3D concept development becomes even more powerful when extended across multiple design options. Kowalski says that Brownlie’s designers regularly use Fusion 360 to choose points where they can branch designs to pursue different solutions. They can experiment with the branches, collaborate with other members of the team (who thereby don’t need to start new designs from scratch), continue to develop the good ones, and roll back to previous versions whenever they need to.

“Sometimes you realize you were at a better spot a few iterations ago,” Kowalski notes. If you don’t have a history-based application like Fusion 360, it’s hard to save parts or iterations to return to later. He compares it to making prototypes by hand: “It’s like you’re working out in the shop and you crack something because you hit it too hard with a hammer. It’s not easy going back.” By contrast, he calls Fusion 360 “painless and easy.” Rather than have to rebuild things entirely, if you need to change direction or simply want to modify a design, you can roll back to an earlier version easily.

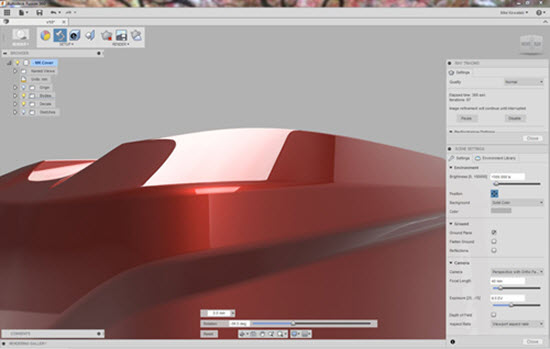

Fusion 360’s rendering power is also a big plus. Previously, Kowalski explains, designers had to render multiple concepts across multiple views to fully understand the form of an object from all angles. “You’re rendering all of those in Photoshop,” he says. “And there may be up to four different views to coordinate.” When you make a change by hand across multiple views, he adds, “It may not be immediately clear how a change in one view will affect the others.” That used to mean more time spent ensuring that everything matched up correctly. The addition of Fusion 360 allows them to streamline that process by switching views with essentially no extra work, and by giving them a true three-dimensional object to evaluate from any angle necessary.

Kowalski shares the example of a client project that was on a very tight timetable: just three weeks from initial concept sketches to modeled parts. The cloud rendering feature in Fusion 360 allows for designs to be rendered using remote computing power, allowing designers to continue working with a model as renderings run in the background. Because “it’s so easy to render” in Fusion 360, the team was able to create 15 different variations of color and material—in 10–15 minutes each, not the 90–120 minutes it would have taken with other software.

Most importantly, the client was impressed that Brownlie could deliver so many high-quality designs with a one-day turnaround. “Without the cloud rendering,” Kowalski says, “that just physically wouldn’t be possible.”

“Printed-out renderings are great to evaluate from an aesthetic point of view,” Kowalski says, “but it’s not always the same thing as being able to see how something really works.” Having prototypes early on in the design process, he adds, helps you answer “How does it feel and work in your hand?”

Recently, when the team was developing designs for a handheld medical device, they used Fusion 360 to create 3D prints for eight different concepts early in the process. They got feedback on the prototypes from a user group of clinicians who could draw on their professional experience to tell the designers exactly how the device would be operated in the real world. Kowalski says that the direct feedback from end users allowed the Brownlie team to “very quickly home in” on the most fruitful design directions.

While other software packages can enable 3D printing, none of them was as easy to use as Fusion 360—or anywhere near as affordable. “Having the ability to add multiple seats of the software at such a low cost has allowed us to easily integrate it into our early concept development,” Kowalski says. “Combined with the in-person and online support we’ve received for learning the software from the basics on up through advanced techniques, it’s been an excellent addition to our process.”

Today, Fusion 360 is helping Brownlie connect its designs with real-world needs even with products that are still in embryo.

As Kowalski says, “Sometimes you need to see and hold the idea in real life.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.