This post is also available in: Deutsch (German)

Are you considering migrating from SolidWorks and are curious about the differences between Autodesk Fusion vs. SolidWorks? This migration guide will highlight what sets Fusion apart, the key steps to successful migration, and the resources to help get you there.

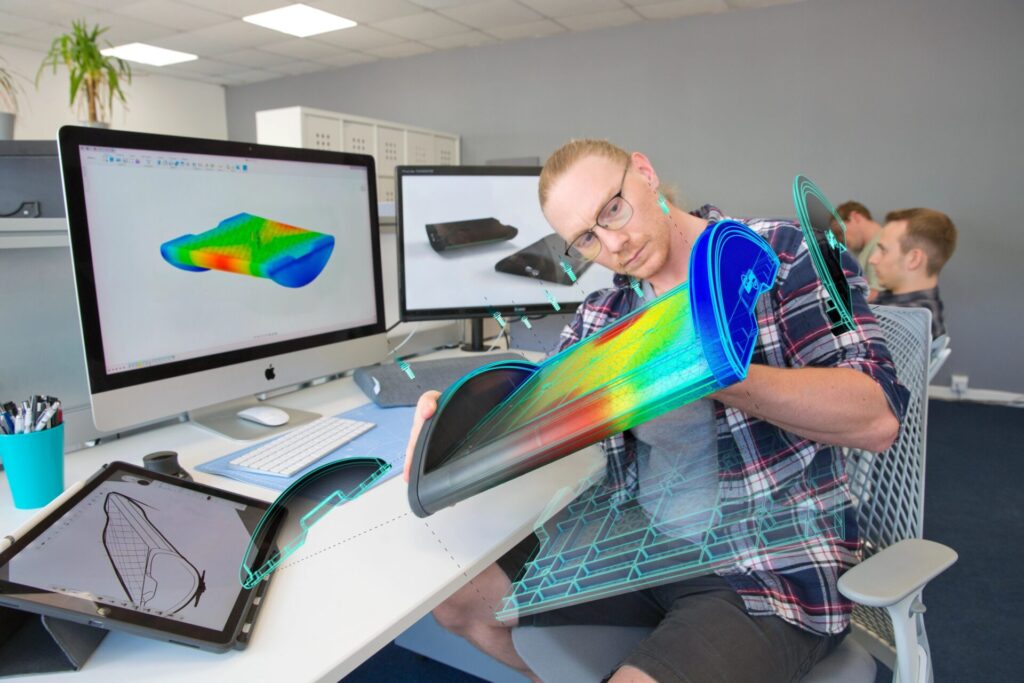

Welcome to Fusion and the Autodesk ecosystem of tools that help you design and make anything!

This guide is your first step to success with migrating from SolidWorks to Fusion. It will help with a seamless onboarding experience and give you the tools and information you need to be successful. Although this is aimed at those from a SolidWorks background, it can be helpful to anyone learning Fusion. Let’s get started.

Table of Contents

- Autodesk Fusion: Empowering designers and engineers

- Key steps for a successful migration

- Shifting your 3D modeling workflow from SolidWorks to Autodesk Fusion: Embrace the familiarity

- Migrating legacy designs from SolidWorks to Autodesk Fusion: Simplified transition made easy

- Take advantage of extensive learning resources

- Embrace the future: Fusion leads the way in design and manufacturing

Autodesk Fusion: Empowering designers and engineers

Before we get into the detailed features to take advantage of, what sets Autodesk Fusion apart from SolidWorks? Fusion offers impressive advantages, making it a top choice for designers, fabricators, and engineers. Here are six key benefits of Fusion you may or may not have already realized during your search for a new tool:

1. Integrated and extensible ecosystem

Autodesk Fusion is not just CAD software. It’s a comprehensive ecosystem that integrates CAD, CAM, CAE, and ECAD (electronic CAD) tools. This integration streamlines your design and manufacturing workflow, allowing you to transition from Design to manufacturing seamlessly.

In addition to CAD tools, the CAM capabilities in Fusion enable you to generate toolpaths and simulate CNC machining processes, ensuring your designs are ready for production. The CAE tools in Fusion also provide simulation and analysis capabilities, allowing you to validate your designs and optimize performance. Furthermore, the ECAD capabilities in Fusion enable seamless collaboration between mechanical and electrical design teams.

2. Collaboration and data at the center

Cloud collaboration in Fusion is a significant game-changer. You can seamlessly share your designs with your team or clients, enabling real-time collaboration and eliminating file exchange hassles. Accessing your projects from any device, anywhere enhances flexibility and productivity in today’s hybrid, fast-paced work environment.

Moreover, collaboration in Autodesk Fusion goes beyond traditional desktop-based software. Browser-based collaboration enables seamless, real-time communication across different locations and devices. Designers can easily share their designs with stakeholders, invite others to review and comment, and make design changes collaboratively.

Data security is also a top priority in Fusion. We’ve implemented robust security protocols to safeguard your valuable design files. You can have peace of mind knowing that your data is securely stored and backed up, minimizing the risk of data loss. For more information check out these resources.

Solidworks to Autodesk Fusion: Seamless Collaboration

Autodesk Fusion Cloud Security Whitepaper

3. Affordable subscription options

Affordability is another significant benefit of Fusion. Unlike SolidWorks, which typically requires a substantial upfront investment, Autodesk Fusion adopts a subscription-based model with a more accessible price point. By providing high-quality tools at an affordable cost, Fusion democratizes access to advanced design and manufacturing capabilities.

4. Autodesk Fusion extensions

Fusion extensions allow you to select and subscribe to the tools that align with your current needs. Giving you the ability to enhance your capabilities in advanced manufacturing, product design, and manufacturing-aware processes. The flexible pricing structure of Fusion ensures that you only pay for what you need, avoiding the limitations and complexities of SolidWorks’ rigid pricing system. By embracing the extension network, you can unleash your full potential, push the boundaries of your designs, and stay ahead in today’s rapidly evolving industry.

Explore Autodesk Fusion Extensions

5. Partner ecosystem

As new technologies and workflows emerge, Fusion collaborates with hardware manufacturers to develop and integrate cutting-edge extensions into its ecosystem. This commitment to staying at the forefront of innovation ensures that you have access to the latest advancements in design and manufacturing, enabling you to stay competitive and drive your business forward.

6. Ease of use

Fusion comes with a robust feature set, but it still remains user-friendly. Its intuitive interface, learning resources, and supportive community ensure that you can quickly adapt to the software. Whether you’re a seasoned pro or just starting, its ease of use facilitates a smooth onboarding process and minimizes the learning curve. Focus on unleashing your creativity and realizing your design visions without getting bogged down by complex software.

Key steps for a successful migration

Transitioning from SolidWorks to Autodesk Fusion opens up exciting possibilities for designers and engineers. As you transition, there are action items to keep in mind to ensure a seamless workflow shift.

1. Familiarize yourself with the interface

The interface of any design software plays a crucial role in the user experience, and Fusion is no exception. Upon launching Fusion, you’re greeted with a clean interface that balances functionality and simplicity. Getting familiar with the Fusion interface is critical to unlocking its full potential and harnessing its powerful capabilities.

To navigate the interface effectively, familiarize yourself with the various menus, tools, and panels. The toolbar at the top of the interface provides quick access to commonly used tools and commands. The Model Browser on the left side allows you to organize and manage your design components, sketches, and construction features. The Design Timeline, situated at the bottom, is a powerful feature that captures the history of your design. You’re able to revisit and modify previous actions at any point in your design process.

2. Pay attention to key terminology

As you delve deeper into Fusion, pay attention to the terminology and organization of the Fusion interface. While some concepts and tools may resemble CAD software, Fusion has a unique language and workflow. Understanding fundamental concepts like sketches, components, assemblies, parametric modeling, and design history features will enable you to effectively leverage the robust capabilities of Fusion.

By exploring Fusion, you’ll naturally become proficient with the software. Take the time to explore the workspaces, menus, and tools, and leverage the available learning resources to enhance your understanding. With a little practice, you’ll quickly find yourself harnessing the power of Fusion to bring your design ideas to life.

Shifting your 3D modeling workflow from SolidWorks to Autodesk Fusion: Embrace the familiarity

If you’re making the switch from SolidWorks to Autodesk Fusion, you may wonder about the process of transferring your modeling techniques. Rest assured, the transition is more manageable than you may think.

Fusion offers a powerful combination of transferable modeling techniques and an intuitive interface, making it easy to adopt and deploy in your design process or business. Familiarity with sketch-based parametric modeling, mesh modeling, and T-splines in Fusion, along with its seamless integration of sheet metal design, streamlines the transition from SolidWorks and ensures a short adjustment period.

Here are seven key Fusion terms and features to familiarize yourself with:

1. Fusion workspaces

At first glance, you’ll notice the different workspaces available in Fusion. Each workspace (model, sculpt, patch, etc.) is tailored to a specific design task. This allows you to focus on the tools and functionalities relevant to your project. Exploring these workspaces and understanding their purposes is a great starting point in your journey toward mastering Fusion.

2. Assemblies in Fusion

Fusion enables you to create complex assemblies by streamlining a number of modeling systems for ease of use. Multiple components, bodies, externally referenced parts, and even third-party CAD are all ways a single large assembly can be assembled in Fusion.

Be sure to take advantage of the assembly features in Fusion, such as the joint tool. This tool allows you to define and simulate realistic mechanical connections between components. The design timeline in Fusion enables you to make changes to individual components within the context of the assembly. It ensures design integrity is maintained throughout the iterative process. Additionally, the visualization tools in Fusion allow you to visualize and animate your assemblies, aiding in design communication and verification.

In addition to those tools and traits, Autodesk Fusion leads the field with assembly concurrency, which allows multiple team members and collaborators to work on a single document without stepping on each other’s toes. With revision control, assembly reservations, and more working with groups is easier than ever. Take a look at the following resources to familiarize yourself with assemblies in Fusion:

SolidWorks to Autodesk Fusion: Assembly Design

3. Sketch-based parametric modeling

One of the standout features of Fusion is its powerful parametric design capabilities. Parametric modeling allows you to create intelligent, feature-based designs that capture design intent and enable easy modifications. Understanding how to leverage parametric design in Fusion is a must. It will enable you to maintain design intent and easily make design changes.

With Fusion, you can define and control relationships between features, dimensions, and constraints. Ultimately, this empowers you to iterate and adapt designs quickly. Take the time to explore the parametric modeling tools in Fusion, such as sketching, constraints, and the design history timeline.

Sketch-based parametric modeling in Fusion will feel familiar and comfortable for those accustomed to SolidWorks. You can leverage your existing skills in creating sketches, extruding features, and defining relationships to maintain design intent and make modifications quickly. The sketching tools in Fusion provide a user-friendly environment, enabling a smooth transfer of modeling techniques from SolidWorks.

SolidWorks to Autodesk Fusion: 3D Modeling Made Easy

4. Mesh modeling

In addition to sketch-based modeling, Fusion offers powerful mesh modeling capabilities. The intuitive mesh modeling tools allow you to create and refine intricate, organic shapes with precision. This opens up new possibilities for designers working on complex designs or artistic projects. The mesh modeling workflow in Fusion seamlessly integrates into its interface, ensuring a straightforward transition from SolidWorks to explore the world of mesh modeling.

5. T-Splines

T-Splines in Autodesk Fusion (also called form modeling) add another dimension to your design capabilities. They allow you to create smooth, freeform organic surfaces while maintaining the parametric and feature-based benefits of sketch and direct modeling techniques in Fusion. This integration of T-Splines offers a versatile approach, enabling you to combine traditional solid modeling with complex, intricate geometry.

6. Sheet metal

The seamless integration of sheet metal design in Fusion further enhances its versatility. You can leverage parametric modeling tools to create accurate sheet metal components, unfold them into flat patterns, and simulate their fabrication and assembly. The sheet metal features in Fusion streamline the design iteration process and ensure accurate manufacturing preparation for sheet metal products.

Solidworks to Autodesk Fusion: Sheet Metal Mastery

7. Fusion Team

One of the critical features of Fusion is Fusion Team, a collaborative workspace that enables teams to work together efficiently. Fusion Team provides a centralized hub for storing, organizing, and managing design files, allowing team members to access the latest versions and collaborate in real time. The data panel in Fusion provides a clear overview of project files, enabling easy navigation and quick access to relevant design data. By leveraging Fusion Team and the Data Panel, teams can manage their design files effectively, reducing confusion and ensuring everyone is working with the most up-to-date information.

SolidWorks to Autodesk Fusion: Data Management Made Easy

Migrating legacy designs from SolidWorks to Autodesk Fusion: Simplified transition made easy

Suppose you have legacy designs created in SolidWorks and are looking to migrate them to Autodesk Fusion. In that case, you’ll be pleased to know that the process is straightforward and hassle-free. Fusion offers seamless integration with SolidWorks files, allowing you to import your existing CAD data and convert it to the history-based modeling format Fusion offers, making the transition smooth and effortless.

How to import files into Fusion

Fusion provides an easy-to-use import feature designed explicitly for SolidWorks files. Select the SolidWorks file you wish to import. Fusion will intelligently recognize the file format and import the CAD information into its environment. This capability eliminates manual reconstruction or redesigns, saving you valuable time and effort.

Once imported, history-based modeling allows you to leverage the CAD information from SolidWorks and convert it seamlessly so you can easily modify, iterate, and adapt your existing designs within Fusion. By retaining the history of your models, Fusion empowers you to make design changes efficiently while maintaining the integrity of your original SolidWorks data.

File support

Autodesk Fusion sets itself apart with its ability to open and work with multiple CAD file types across its various workspaces. Whether you’re working on manufacturing, modeling, rendering, ECAD (electronic CAD), or simulation, Fusion provides compatibility with a wide range of file formats commonly used in the industry. This broad compatibility ensures that you can seamlessly incorporate legacy SolidWorks designs into any stage of your design and manufacturing workflow within Fusion.

You can leverage the imported SolidWorks files in the manufacturing workspace to generate toolpaths, simulate machining operations, and generate CNC programs. The modeling workspace in Fusion allows you to refine and optimize your designs, using the converted CAD information to drive your parametric modeling process. The rendering workspace enables you to create realistic visualizations and presentations using your legacy SolidWorks data.

For electronic designs, the ECAD capabilities in Fusion support importing and working with legacy PCB (printed circuit board) files, allowing you to transition your electronic designs from SolidWorks to Fusion seamlessly. Lastly, the simulation workspace in Fusion enables you to perform analysis and testing using the converted SolidWorks data, facilitating the evaluation and validation of your designs. To get started, view the following resources:

SolidWorks to Autodesk Fusion: The Ultimate CAM Guide

SolidWorks to Autodesk Fusion: Electrify Your ECAD

Take advantage of extensive learning resources

There will naturally be some adjustments and new concepts to grasp when transitioning from SolidWorks to Autodesk Fusion. However, the process is relatively easy. With a little exploration and practice, you’ll soon find yourself creating stunning designs with confidence and ease.

With Fusion, you’re not just gaining access to a software tool; you’re joining a vibrant community of innovators, designers, and engineers. Tutorials, videos, and community support via forums can help you quickly grasp the interface and functionality and discover the most efficient workflows. Additionally, there’s a Fusion “Get Started” workspace in the product. Here, you’ll find interactive tutorials and guided exercises to get hands-on experience and confidence as you explore the software.

Here are some helpful links to get you started:

- This is the most product-centric walkthrough. It focuses on the exact picks and clicks you need to succeed. It’s maintained by a group of folks that with every release updates based on our newest technology releases. So, if you’re someone who needs the nitty-gritty and likes to read, here you go.

- Another excellent source for help with the interface is this transition guide created by our friends in User Experience Design. They’ve done a great job of creating a high-level overview through some big-ticket items and related videos.

- Finally, if you’re someone who likes to learn through watching, check out our YouTube channel. Subscribe to get updates on new content that’ll help you get the most out of Fusion.

Embrace the future: Fusion leads the way in design and manufacturing

Fusion stands out as the superior tool when compared to SolidWorks, offering a comprehensive suite of professional-level CAD, advanced CAM, and integrated systems that cover a wide range of design and manufacturing needs. By adopting Fusion, you’ve made a smart choice that opens up endless possibilities for your design and manufacturing endeavors.

The unique capabilities of Autodesk Fusion will help you discover new efficiencies and possibilities in your design process, ultimately enabling you to bring your innovative ideas to life with confidence and precision. With Fusion’s easy deployment, there is little to no downtime as you transition from SolidWorks, allowing you to quickly adapt and continue working on your projects without disruption.

The future is bright, and we’re here to empower you every step of the way. Welcome to the Autodesk Fusion community, where you really can make anything.