& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

See how Sifer srl leveraged various advanced tools in Fusion to design custom tooling that enables scalability and increases productivity.

Sifer srl is a 25-person company based in Naples, Italy, known as a reseller for industrial components. The company also has a precision mechanics division that designs, makes, and certifies bespoke complex systems for clients.

Designing and manufacturing for the aerospace industry, in particular, means always staying ahead of the curve. Sifer srl is doing just that with its innovative new approaches and designs for incorporating robotics and subtractive manufacturing into its process — all powered by Autodesk Fusion.

When Sifer srl landed a project for a major installation of rivets in paneling for a large aircraft, the company began thinking of a way to make its development process more efficient. CNC machines are meant for cutting only — not cutting and assembly combined. To bridge this gap and speed up its workflow, the team decided to design and build a new machine tooling unit specifically for a 6-axis KUKA robot to perform this application.

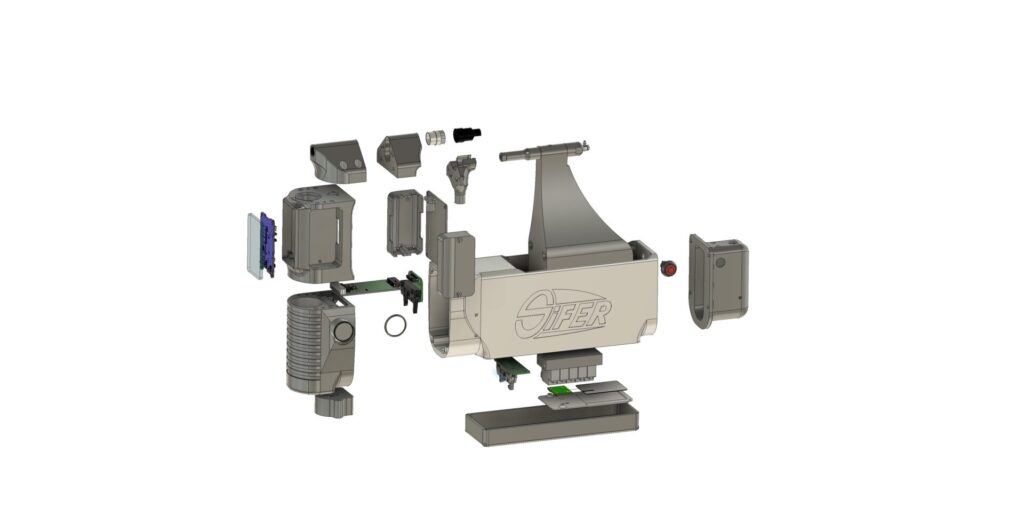

The result? Sifer srl designed a new end-of-arm tooling unit for drilling, riveting, and fastening in Fusion. Thanks to the custom build, the KUKA robot can do everything it needs to do in one operation with precision, accuracy, and speed — and without having to disassemble the parts first. The end customer benefits by reducing the physical burden of a human performing this task, which in turn increases productivity, repeatability, and scalability. Check out how it works in the below video:

“Fusion is very easy to use and user friendly. We were able to learn a lot of functionality in Fusion right within the software. I think it’s very important for software to help the user learn in a short amount of time and in an easy way.”

—Francesco Luzzi, Chief Operating Officer, Sifer srl

The resulting tooling unit is extremely versatile for reaching awkward spots. Without digital commissioning, a team designing such a tool would typically have to assume the robot could reach or twist to a certain area during the design process. In Fusion, however, the Sifer srl team could see and solve issues with digital iterations to ensure the robot would perform as expected in the real application.

The Sifer srl team is now increasingly designing and manufacturing application-specific machines for drilling and fastening. The KUKA robot tooling application was especially important to design with the aerospace industry’s challenges in mind. Thanks to the Autodesk Fusion Insider Program, Sifer srl could leverage an early technology preview of the Robotics Add-in for Fusion to support its development process.

“For the KUKA robot project, it was required to guarantee the repeatability of the process because the industry is trying to industrialize as many processes as possible,” says Francesco Luzzi, Chief Operating Officer, Sifer srl. “With the robot application we developed in Fusion and the early access to the Fusion Robotics Add-in, we can guarantee to the customer that the work and timing are qualified to increase production from the very beginning.

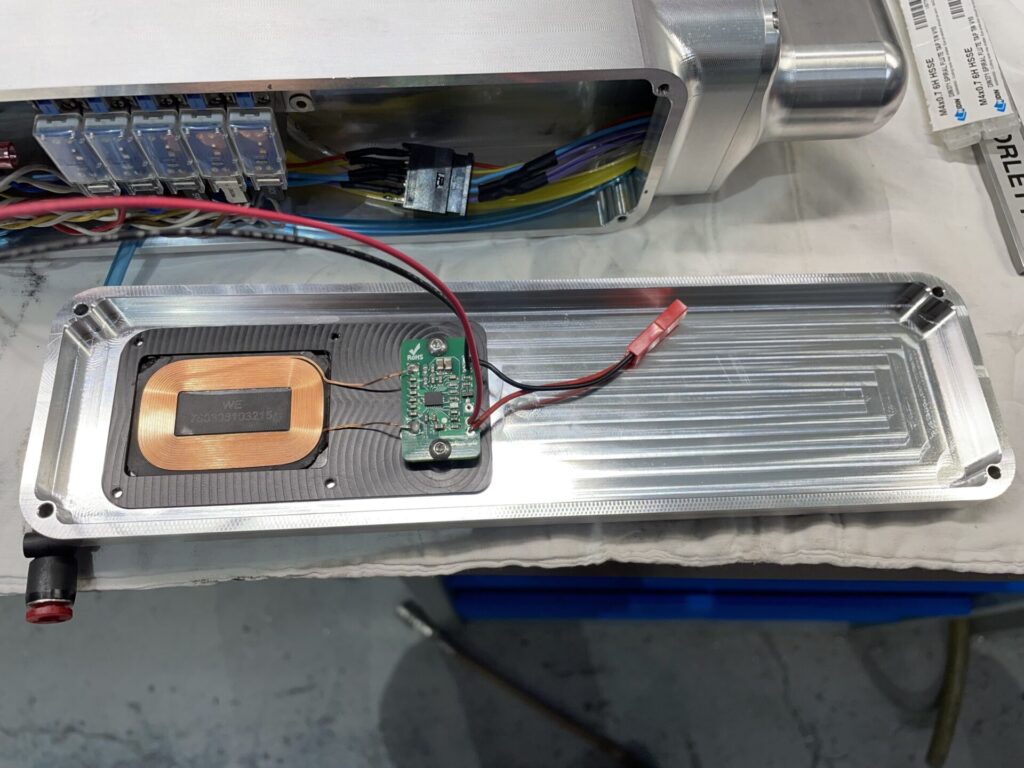

Collaboration was also key to the design of the robot. Sifer srl worked with Vasile Elettronica srls to design electronics in Fusion. “We could both easily see the same things at the same time, and it made the process much easier,” Luzzi says.

“Our mechanical division was established specifically to provide us with capabilities to produce our own parts that we designed. But this means we need to be fast and competitive in the production and development of our products. Thanks to the Fusion Machining and Nesting Extensions, we can use all the potential of our multi-axis CNC machines and guarantee the best surface finish and appeal.”

—Francesco Luzzi, Chief Operating Officer, Sifer srl

Even though Sifer srl is a small business, many Fusion features have helped them achieve the same complex parts and applications other larger companies might produce. They can also broaden their business reach with the use of the cloud.

“We have to integrate a lot of different technology, powerful motor and electronic devices,” Luzzi says. “We need the most powerful software like Fusion to create very accurate parts and integrate all the robotics technology, motor, and electronic devices. We use all the functionality of the Fusion 360 Manufacturing Extension to realize all our parts, including nesting and fabrication tools to save time and materials during production.

“I also love how we can share a project with other people anywhere in the world,” he continues. “We can all work together wherever we are.”

Learn more about the technology preview for the Fusion 360 robotics add-in and how to gain early access at the link below.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.