Save time, reduce errors, and optimize material utilization with Fusion 360 Nesting and Fabrication Extension.

In the world of fabrication and manufacturing, efficient material usage is crucial. Nesting software is a powerful tool that can help optimize material usage, and the Fusion 360 Nesting & Fabrication Extension enables users to leverage this functionality seamlessly.

What is nesting software?

Nesting software refers to specialized applications that arrange 2D shapes or parts onto flat sheets of material in the most efficient way possible. It aims to minimize waste by maximizing material usage and reducing cutting time. By intelligently positioning and nesting shapes, manufacturers can significantly improve their production processes and reduce costs.

How to maximize efficiency with nesting software

To make the most of nesting software, manufacturers can employ various techniques and strategies to maximize efficiency and material utilization.

Automated nesting

Automated nesting tools are designed automatically optimize the arrangement of parts. By leveraging automated nesting, manufacturers can achieve efficient nesting layouts quickly and accurately, minimizing waste and improving productivity.

Material optimization techniques

Manufacturers can also implement material optimization techniques to further enhance efficiency, including:

- Part grouping: Grouping similar parts together can help reduce material waste and improve cutting time. By identifying parts with similar geometries or characteristics, manufacturers can nest them together, maximizing material usage.

- Rotation and mirroring: Rotating and mirroring parts can lead to better nesting outcomes. By exploring different orientations, manufacturers can identify the most efficient arrangement for their parts, reducing waste and improving efficiency.

- Nesting constraints: Setting constraints within the nesting software can help align parts according to specific requirements. For example, aligning parts along the grain direction of the material can improve strength and stability in certain applications.

Fusion 360 Nesting & Fabrication Extension

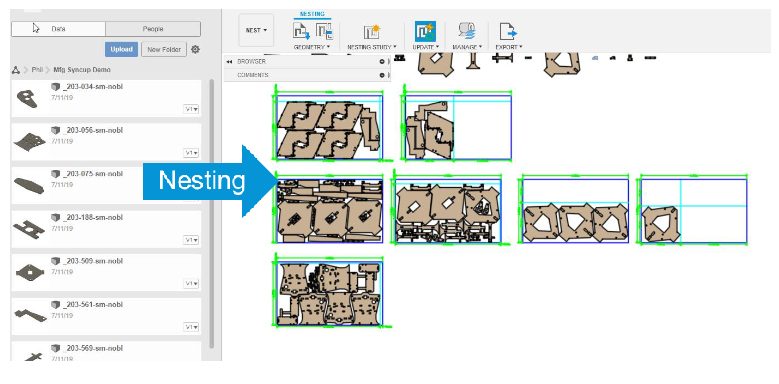

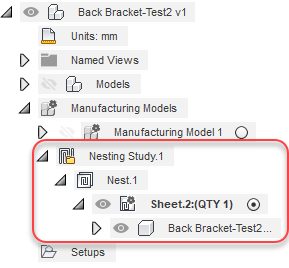

The Nesting and Fabrication Extension is available directly within Fusion. Users can easily transition from the design phase to the nesting phase, ensuring a smooth and efficient process. This also eliminates the need for exporting designs to separate nesting software, saving time and reducing potential errors during the transfer.

This extension offers a range of features, including:

- Associative nesting: Since Fusion 360 offers an integrated CAD/CAM environment, any design changes are automatically consumed by nesting. This ensures you’re always working on the most up-to-date version of a project.

- Automated nesting: Automated nesting intelligently arranges parts for optimal material usage. These algorithms analyze the shapes, quantities, and available sheet sizes to generate efficient nesting layouts automatically.

- Nesting reports: The extension also generates detailed reports, providing information about material utilization, cutting time, and costs. These reports help manufacturers analyze and optimize their processes further.

Benefits of the Fusion 360 Nesting & Fabrication Extension

The Nesting & Fabrication Extension offers many advantages for manufacturers, including:

- Material savings: Nesting optimizes material usage, reduces waste, and lowers material costs. It enables manufacturers to achieve higher material usage rates, ultimately leading to significant savings.

- Enhanced efficiency: By automating the nesting process, manufacturers can improve efficiency and productivity. Manual nesting is a time-consuming task, but with the Nesting & Fabrication Extension, shapes can be arranged quickly and accurately, saving valuable time and effort.

- Reduced production costs: By minimizing material waste and improving efficiency, the Nesting & Fabrication Extension helps reduce overall production costs. This can have a positive impact on a company’s bottom line, making operations more cost-effective.

Check out this step-by-step guide to creating customizable, printable labels for easier part tracking with the Fusion 360 Nesting & Fabrication Extension. And check out this video to see how nests are linked to the design and material settings when making changes and recalculating the nest.

Try the Fusion 360 Nesting & Fabrication Extension

The Fusion 360 Nesting & Fabrication Extension is a powerful tool to optimize efficiency and material usage. By leveraging automated nesting and implementing material optimization techniques, manufacturers can significantly reduce waste, enhance productivity, and lower production costs.

Ready to boost your efficiency? Try the Fusion 360 Nesting & Fabrication Extension free for 14 days.