This post is also available in: Deutsch (German)

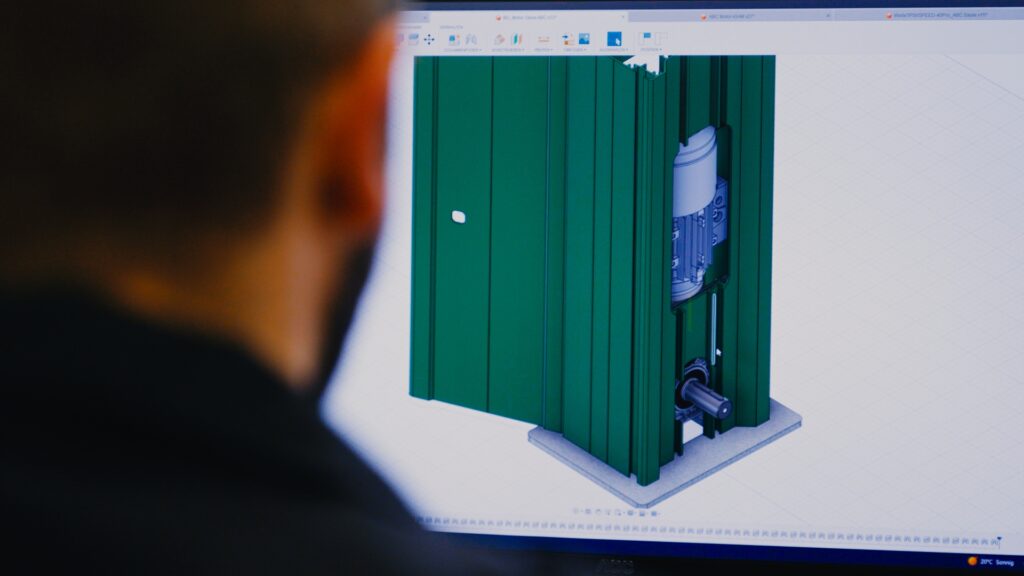

See how Vienna-based automatic gate company tousek leverages Fusion 360 and its extensions throughout its product development process.

Based in Vienna, Austria and currently run by the second-generation Tousek brothers, tousek Ges.m.b.H. is a 50-year-old business focused on designing, manufacturing, and selling automatic gate-drive systems. Their sliding and swing systems for opening and closing garages, gates, barriers, and access control points are sold in 60 countries and are available anywhere from commercial industries to private households.

During the pandemic, tousek experienced a remarkable growth period as people invested more in their homes. At the same time, the company continually faces new challenges with consumer demands for speed and safety combined with changing regulations.

“Each country has its own regulations and its own standards,” says Philipp Tousek, Export Manager, tousek. “When a regulation is changed, we have to react within days or weeks to modify it and replace it accordingly. That means there is a very high demand on our development—especially in the design of mechanical parts.”

With the business expanding quickly and the need to accelerate its product design and manufacturing process, tousek realized it was time for a change.

“We switched to Autodesk Fusion 360 because we were at the limits of our previous CAD programs,” says Mario Tousek, Managing Director, tousek. “The requirements became faster and faster, and the linking of different departments became more important, so there was a need for new software.”

“We merge electronics with mechanics. There are very few software firms that are capable of doing this. Autodesk Fusion 360 was therefore the logical choice, as they connect all departments, electronics, and mechanics for us.”

—Mario Tousek, Managing Director, tousek

New design and collaboration opportunities

tousek has rolled out Fusion 360 to multiple team members, including access to the Fusion 360 Generative Design Extension, Simulation Extension, Manage Extension , and Product Design Extension. With a complete manufacturing solution now in hand, tousek can utilize features that were previously unaffordable with SolidWorks.

The Manage Extension solves revision and release challenges they previously faced when using SolidWorks. And with the Product Design Extension, tousek can explore manufacturable plastic parts and solve plastic engineering problems. At the same time, Fusion 360 provides an easier path and automation for their mechanical designs overall.

“What I like most about Fusion is that it makes it much easier to collaborate with the mechanical development team,” says Oliver Perner, Electronics Developer, tousek. “Things that are designed with Fusion 360, such as control housings, are then very easy to transfer to the PCB. I have everything on the screen and don’t have to print it out beforehand, measure, and do everything by hand.”

Connecting design and manufacturing across multiple locations

The tousek team currently designs, manufactures, and assembles its products in the same facility. This provides a good deal of flexibility, but the location is too small to keep up with growth. The company is building a larger manufacturing facility on the outskirts of Vienna. They’ll keep design and office work in the current building while greatly expanding manufacturing and assembly capabilities in the new one.

For the first time, everyone will no longer be under the same roof. Cloud-based storage and the ability to access real-time data from anywhere with Fusion 360 will allow the manufacturing team to access accurate data on the factory floor, resulting in fewer errors and correctly manufactured assemblies every time.

“We have an exceptionally motivated team, and we’re perfectly equipped in terms of software technology to be able to react to future changes,” says Philipp.

Ready to open the door to your business’s growth?