& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

2 min read

The term “smart factory” is more than just a buzzword — it represents a significant shift in the way we think about and approach manufacturing. This article explores what a smart factory is and its role in today’s fast-paced product development landscape.

From a high level, the smart factory is a highly digitalized and connected manufacturing facility that leverages technological innovations to boost productivity and efficiency. Notably, the smart factory is marked by the use of cutting-edge technologies, such as the Internet of Things (IoT), robotics, machine learning (ML), and data analytics to create a production environment that self-optimizes and adapts to new conditions in real-time.

In a smart factory, machines and systems communicate with each other, sharing data and leveraging ML to help make autonomous decisions. This level of interconnectivity and automation allows for a more flexible and efficient production process. This reduces downtime and waste, ultimately leading to higher productivity and lower costs.

The rise of smart factories is not just a trend: it’s a response to the increasing demands of the modern market.

Today’s consumers expect high-quality products that are personalized to their needs and delivered at an ever-faster pace. To meet these expectations, manufacturers must be able to adapt quickly to changes in demand, customize production at scale, and minimize lead times. This is where smart factories come into play.

By harnessing the power of advanced technologies, smart factories can monitor the entire production process in real-time, predict and prevent potential issues before they occur, and make instant adjustments to meet changing demands. This process not only improves efficiency and productivity but also enables a level of customization and speed that was previously unimaginable.

Autodesk Fusion and Fusion Operations are leading solutions that support the needs of the modern smart factory.

The first step in production is design. Fusion is a comprehensive, integrated CAD, CAM, CAE, and PCB tool that supports designers and engineers throughout the product development process. The tool’s all-in-one nature allows industrial designers, mechanical engineers, electronics engineers, machinists, and other stakeholders to collaborate without requiring any file format, system, or tool change. It also seamlessly brings teams into the production process by generating machining files suitable for mass production, along with bills of materials, supply chain management, and engineering documentation.

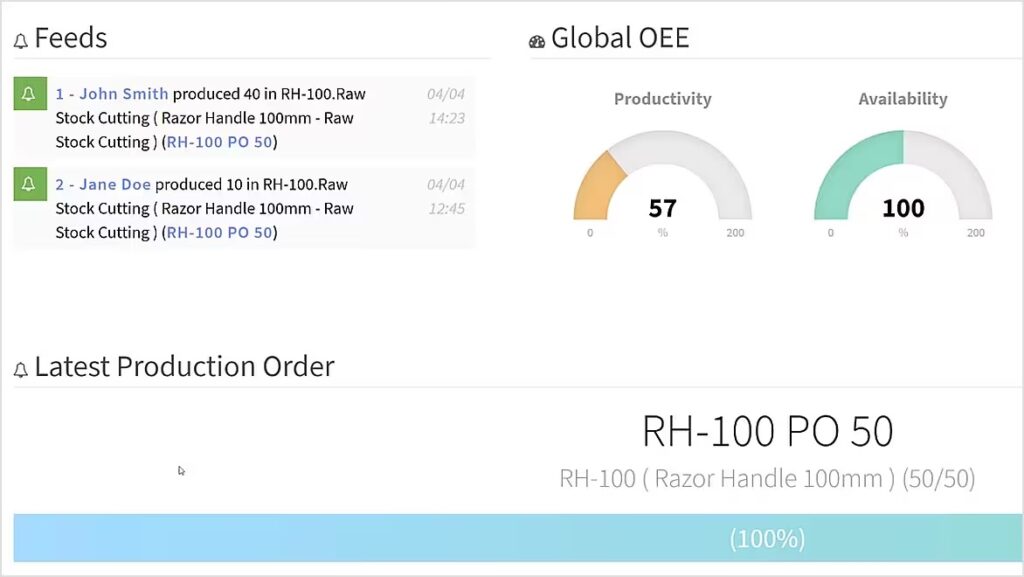

When it comes time for the production process, Fusion Operations is a production management and production floor tracking software that helps teams stay on track. The tool digitalizes the shop floor, providing actionable analytics dashboards to improve efficiency and reduce waste. Additionally, Fusion Operations integrates data from the product development process with real-time and historical data from machines, operators, and supply chain stakeholders. Teams can deploy it on mobile devices and tablets for easy use on the shop floor.

The cloud-based nature of both Fusion and Fusion Operations facilitates connectivity between the two, offering benefits such as user management, data integrity, cross-platform collaboration, and interoperability across different engineering disciplines. These features contribute to an environment with lower overhead, error reduction, and reduced redundancy.

Overall, Fusion and Fusion Operations equip designers, engineers, and manufacturers to maximize their capabilities. What’s the result of using these tools in conjunction? High-quality products, made with remarkable speed and efficiency—the true essence of a smart factory.

Ready to start your journey with Autodesk Fusion and Fusion Operations?

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.