& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

Molg takes circular manufacturing to the next level. See how its microfactory precisely disassembles consumer electronics for reuse.

When Molg co-founders Mark Lyons and Rob Lawson-Shanks were working at their last quickly scaling consumer electronics startup LifeFuels, they were confronted with the unfortunate but common challenge of how to responsibly handle the increasingly large volumes of hard-to-recycle, end-of-use product. Lessons learned throughout the production of their first flagship product and then the return and end-of-life problem sparked the idea for their latest venture.

“We started thinking about what we wanted to do next, and we recognized how much waste there is in the manufacturing industry,” says Mark Lyons, co-founder and chief technology officer, Molg. “There is a huge problem with e-waste, especially at end-of-use. We started to think about creating another product to approach manufacturing differently. And then we thought about the product actually being a (de)manufacturing platform.”

Their ideas crystallized around the notion of a complete solution for circularity that would encompass the design phase, manufacturing of products, and ultimately the disassembly of these products for reuse or recycling. With the goal to pursue industry-wide adoption of the circular economy and avoid further e-waste ending up in landfills, Molg was born.

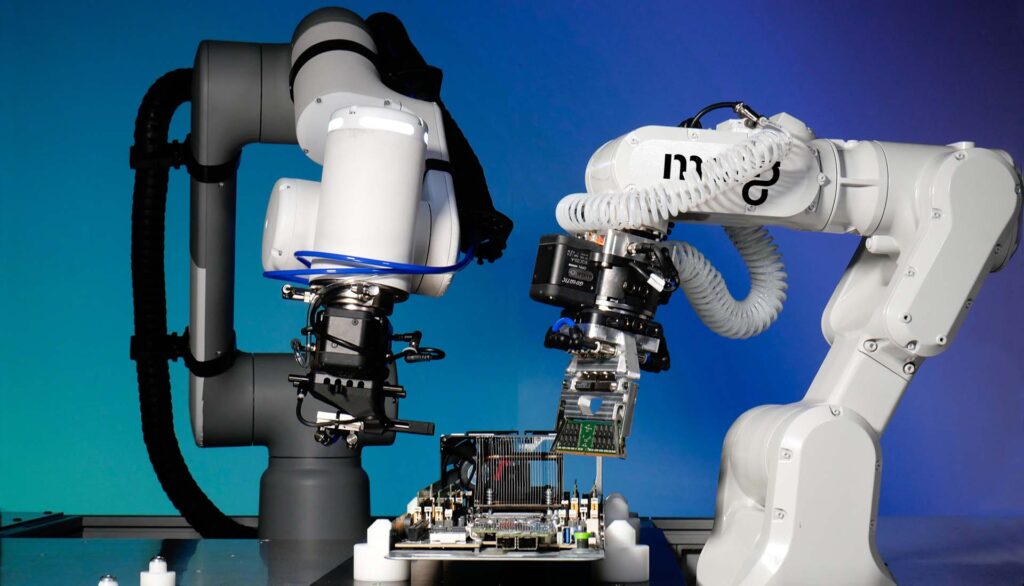

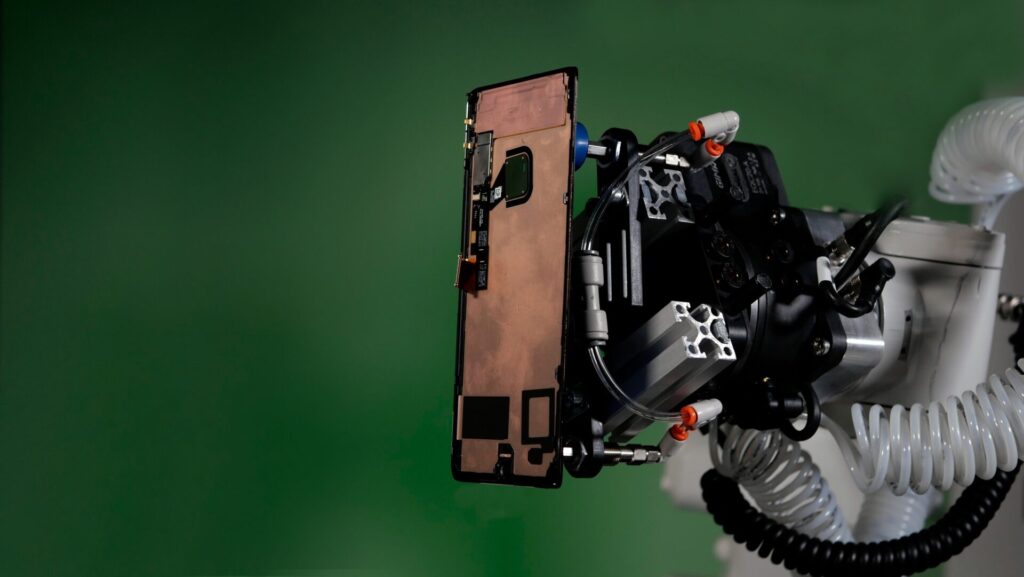

Molg’s current, principal offering is a state-of-the-art microfactory, which is even smaller than you might imagine. It’s a two-meter cube with multiple robotic arms and a workspace capable of processing anything up to the size of a rackmount server. No smashing or shredding of electronics here. A precise stream of components is “harvested” for reuse or recycling.

Take a laptop, for example, and its mix of components. Some parts may be perfectly functional for a second-life product while others may be too worn and require recycling. With Molg’s microfactory, everything can be identified and sorted, down to the screws, metals, and recycling codes of plastics. Molg is currently working in various fields for disassembly, including clients in the server and laptop space who want to recover high-value components.

But how does the robot know what to take apart? Instead of leaning heavily on artificial intelligence for in-process discovery, Molg is taking a novel approach with assembly intelligence.

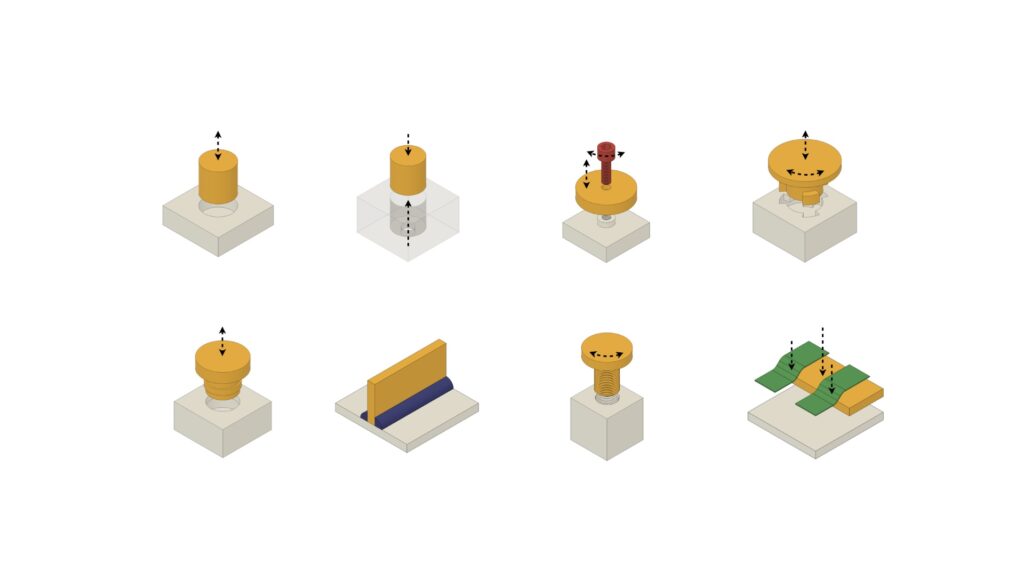

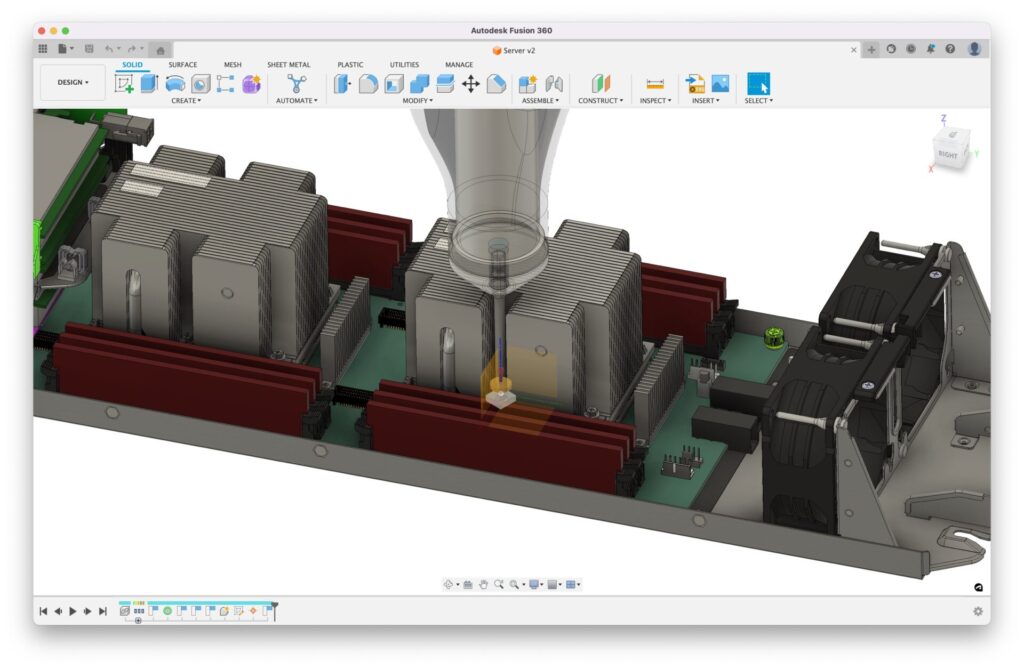

“We’re going beyond the CAD model,” Lyons says. “This is where our solution meets up with Autodesk Fusion. We use Fusion for all our day-to-day design efforts, but it’s also a component in our toolchain. We’re creating this catalog of assembly patterns that encompass most real-world products out there for the microfactory to use and identify when disassembling a product.”

When defining a new assembly pattern, they create a simplified model using Fusion. That pattern is then parameterized (lengths, widths, tolerances, etc.) and captured in a data structure within the system. In the context of product design, they use a Fusion plugin to generate assembly features and capture assembly parameters. Finally, a design package is exported that contains the model geometry and a collection of assembly metadata.

“The plugin architecture allows us to extend the capabilities of Autodesk Fusion rather than building a complex design tool from scratch,” Lyons says. “Fusion’s open API uniquely enables our application and facilitates a seamless design workflow.”

With the design packages, different Re-X jobs (i.e., repair, remanufacturing, recycling, etc.) can be dynamically synthesized on the fly using this assembly intelligence, in addition to visual inspection, device telemetry, and service data. And it all happens incredibly quickly, with a Re-X job being synthesized and a full server being disassembled and processed to its individual components in less than five minutes.

“We‘re starting to use the Autodesk Fusion Product Design Extension because it’s capturing things like feature definition. I’m really excited about it.”

—Mark Lyons, Co-founder and Chief Technology Officer, Molg

With the huge amount of cross-functional work going into Molg’s microfactory and manufacturing platform, many team members are working in various areas and wearing many different hats. Lyons appreciates the collaboration available with Fusion.

“We have a lot of prior experience with Fusion,” Lyons says. “But back when I was using SolidWorks, everything was very siloed. Collaborating with all our team members in Fusion is a huge benefit for us.”

Lately, the Molg team has been doing quite a bit of in-house machining and CAM work. “CAM in Fusion is extremely competitive in the market for those capabilities and the price point,” Lyons says.

Closed Loop Partners and Elemental Excelerator are partnering with Molg to support its vision. The company also recently joined the Autodesk Sustainability Tech Partner Program. As Molg continues to make new inroads with the microfactory and platform work across the circular economy, its core mission remains as clear as ever. It’s all about creating a new path for circular manufacturing—from start to finish.

“Circularity is an imperative,” Lyons says. “There simply isn’t a choice. Products need to become circular in their design and take into consideration end-of-life processing. You can design products using sustainable materials. But if you have no way to practically disassemble and process them, then circularity can’t become a reality. We want to be part of that solution.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.