See how Unik Metal uses configurations in Autodesk Fusion to iterate quickly and recieve customer validation.

Customization in architecture and interior design projects adds an extra dimension of complexity to an already complex process. A combination of creativity, accuracy, and open, clear communication with clients is vital to a successful outcome.

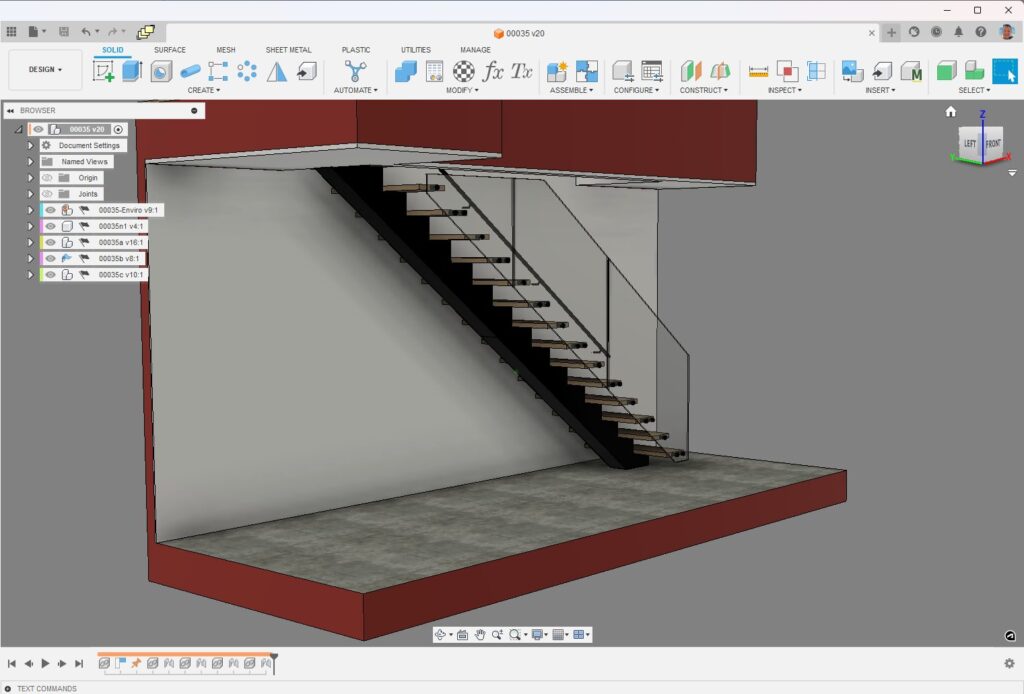

Unik Metal is a company that understands these challenges all too well. The Waterloo-based fabrication studio specializes in a range of custom architectural components, including staircases, metal guardrails, glass walls, and more. Its projects range from personal residences to commercial spaces.

Each space Unik Metal works with has vastly different dimensions and lends itself to multiple potential design outcomes. Founder Francis Deslauriers points out that when creating a staircase, there are so many routes his team could take depending on the space: a glass wall guardrail, a steel guardrail, no guardrail, different color options, a straight or curved design, a design that connects to a wall, a design that doesn’t connect to a wall—the list goes on.

Beyond varying spatial constraints, a successful design hinges on client sign-off, which often takes multiple rounds of revisions once a design is selected. Going through multiple rounds of client feedback also means switching back and forth between multiple design options.

Leveraging Autodesk Fusion

The Unik Metal team relies on Autodesk Fusion throughout their entire design process, including installation drawings, sheet metal nesting, and creating bills of materials. The collaboration opportunities and sharing links for design updates and reviews have made a big difference in working with clients.

“Our customers are really fascinated that they can actually see what’s going to be built to scale and what it’s going to look like,” says Deslauriers. “When they see the design in Fusion, it really gives them more confidence of what will be manufactured.”

Deslauriers is a member of the Fusion Insider Program, so he received early access to test configurations in Fusion ahead of their launch. Soon after testing configurations, he decided to make them an integral part of his team’s workflow.

Unlocking adaptability with configurations in Fusion

Working with multiple design files gets complicated quickly and can lead to dimensional errors or other mistakes during the design process. While on-site, configurations in Autodesk Fusion help Deslauriers ensure all design options fit dimensionally in the space without having to create and edit multiple separate design files.

The Unik Metal team creates each configuration in just a couple of minutes depending on the complexity, which saves time and keeps things organized. Once ready, they send the options straight to the customer for review using the Fusion web viewer. “You simply send a link, and they can view the design in real-time. There’s no need to use an app or anything. Customers, interior designers, and architects love it,” says Deslauriers.

They also do more architectural product work outside of the staircase realm, where they have to create a cohesive look between different structures. So configurations help them reuse parts across multiple products and explore different aesthetic possibilities within the same collection to maintain that cohesive design language.

“Configurations allow me to work on an entire product line inside of one design,” says Deslauriers. “It’s really valuable to be able to see how different parts interact and how we can reuse them.”