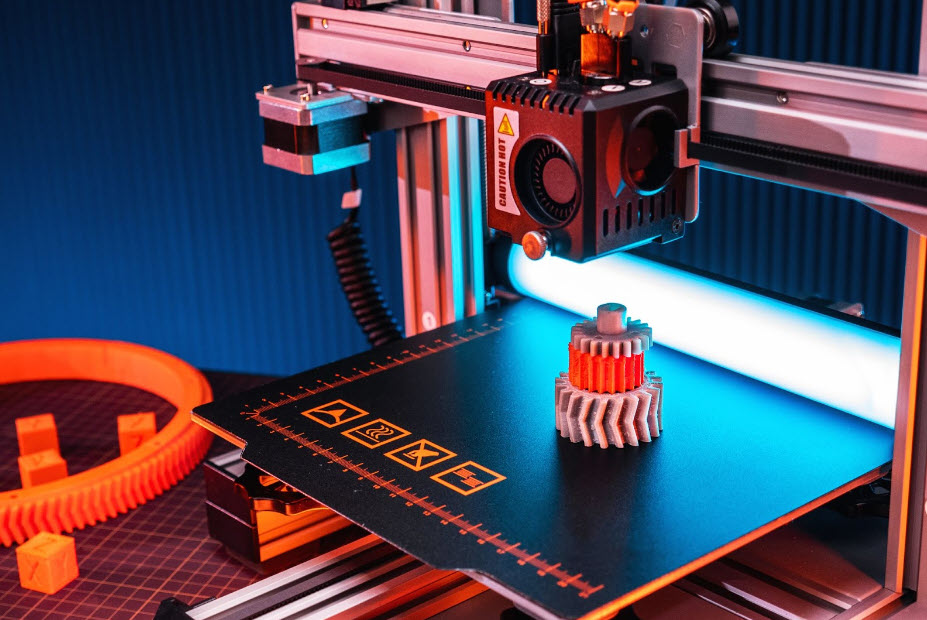

Multi-material 3D printing has many transformative benefits in product design and manufacturing. Autodesk Fusion supports multi-material 3D printing by offering tools for precise design, simulation, and preparation of prints.

In the evolving world of product design and manufacturing, multi-material 3D printing stands out as a revolutionary technology. It offers unparalleled flexibility and creativity. This method of additive manufacturing allows for the creation of complex and customized parts with varied properties, all originating from a single print run. By integrating multiple materials into one print job, designers and engineers can produce parts with unique combinations of strength, flexibility, color, and even electrical conductivity.

Let’s take a look at its benefits and its implications for modern product design.

The technological advancements of multi-material 3D printing

Multi-material 3D printing represents a significant leap in additive manufacturing technology. Traditional 3D printing involves creating objects layer by layer using a single material. This often limits the functionality and aesthetic of the final product. In contrast, multi-material 3D printing allows for the use of different materials within the same object, each selected for specific properties like rigidity, elasticity, or temperature resistance.

The core benefit lies in its ability to integrate different materials into a single print job. This significantly expands the design possibilities and functional capabilities of printed objects. By using this technology, designers can achieve a level of complexity and utility that was previously unattainable with traditional single-material 3D printing methods.

The integration of multiple materials in a single print also allows for the optimization of individual parts of an object when adhering to specific requirements. For example, an item can be designed with rigid internal structures for strength and stability while having flexible external surfaces for enhanced grip or comfort. This marriage of diverse material properties in a single object is especially crucial in industries like biomedical, automotive, and consumer electronics. Here the combination of strength and flexibility is often required.

Additionally, multi-material 3D printing is a step forward in manufacturing efficiency. This technology reduces the need for multiple-part assembly, as an object with varied materials can be produced in one go. This not only decreases production time but also minimizes potential assembly errors, leading to higher quality and more reliable products.

Autodesk Fusion’s relevance in multi-material 3D printing

Autodesk Fusion is a pivotal tool for any designer looking to harness the full potential of multi-material 3D printing. For additive manufacturing, Fusion 360 facilitates the printing of singular bodies with variable print settings, materials, or colors in 3D printing. An example of this is Fusion’s ability to provide tools for slicing bodies in preparation for multi-color and material 3D printing. This feature is crucial for creating separated and perfectly aligned STL files. These are essential for precise and effective multi-material printing.

Fusion also simplifies the design process for multi-material objects. Users can start by creating a component for their dominant material, followed by generating the geometry for the complete part. This method ensures that each material is accurately integrated into the overall design. This is vital for achieving the desired functional and aesthetic properties of the final product.

Finally, Fusion includes a highly capable non-linear study type for simulating the stresses on components with non-linear material properties, such as those produced in 3D printing. This simulation capability is crucial for predicting and optimizing the performance of multi-material prints.

Harnessing Multi-Material

Multi-material 3D printing is transforming the landscape of product design and manufacturing, offering an unprecedented level of versatility and customization. With the ability to print objects using multiple materials, designers, and engineers can create more functional, aesthetically pleasing, and innovative products. Autodesk Fusion plays an instrumental role in this transformation, providing the necessary tools for designing, simulating, and preparing multi-material prints. As technology continues to evolve, the possibilities for multi-material 3D printing will only expand, further enhancing its impact across industries.

Start your 3D printing journey with Autodesk Fusion today.