& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

2 min read

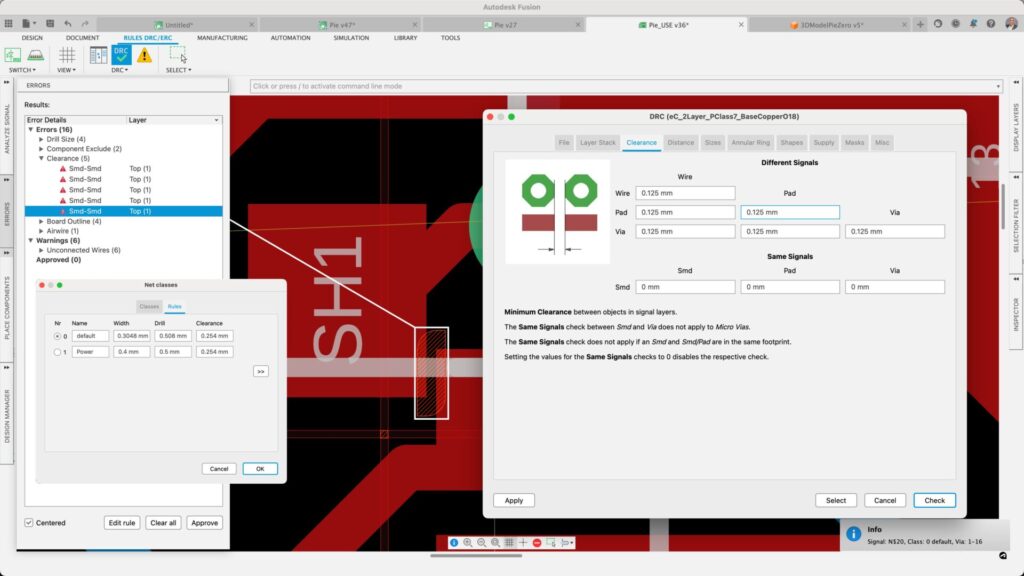

Explore the importance of Design Rule Checking (DRC) in PCB design and how Autodesk Fusion enhances the process.

When designing a product, it’s necessary to ensure that the design has no flaws before sending it to manufacturing. Whether you’re verifying that a component is manufacturable, or optimizing a design for the highest quality in manufacturability, design rule checks are a pivotal part of product design. In the realm of PCB fabrication, there are especially notable limitations to be aware of and check before moving on to the next stage of development. Let’s learn more about design rule checking (DRC) and explore how Autodesk Fusion can help facilitate the DRC process.

At its core, DRC primarily focuses on validating a PCB design against predefined criteria and standards. These criteria often pertain to the capabilities and limitations of manufacturing processes, materials, and the intended functionality of the product. For example, in electronics design, DRC includes checking aspects like spacing between circuit elements, trace width, and hole sizes to ensure they are within the limits that can be reliably manufactured.

The purpose of DRC is to identify potential manufacturing issues early in the PCB design process—thereby reducing costly reworks and delays. While DRC generally refers to PCB design, product design can also encounter some common design rule checks. These include:

A Design Rule Check allows you to establish a set of boundaries for trace widths, component spacing, via diameters, etc. Autodesk Fusion offers comprehensive support for all of these areas and, during a DRC, will flag any concerns.

Fusion’s built-in rule checkers play a pivotal role in comparing design elements against sets of constraints. This feature aids designers in making decisions that are both cost-effective and manufacturable, ensuring that the final product can be produced efficiently and meet market demands.

Learn how to run a DRC in Autodesk Fusion here.

By ensuring that designs adhere to the manufacturer’s capabilities, DRC helps designers create better-quality products with higher yields and a lower chance of failure. With a slew of advanced features to assist the DRC process, Autodesk Fusion is a leading tool for all product design needs. As products continue to become more advanced and complex, DRC features, like those in Fusion, will be necessary for maintaining product quality and reliability.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.