& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

This post is also available in: Deutsch (German) 日本語 (Japanese)

German company Powertrust is innovating entirely new solutions for generators and electricity storage that use the photovoltaic process. With products ranging from residential to agricultural and industrial use, the company’s goal is to deliver renewable energy systems that provide sustainable, safer options for everyone.

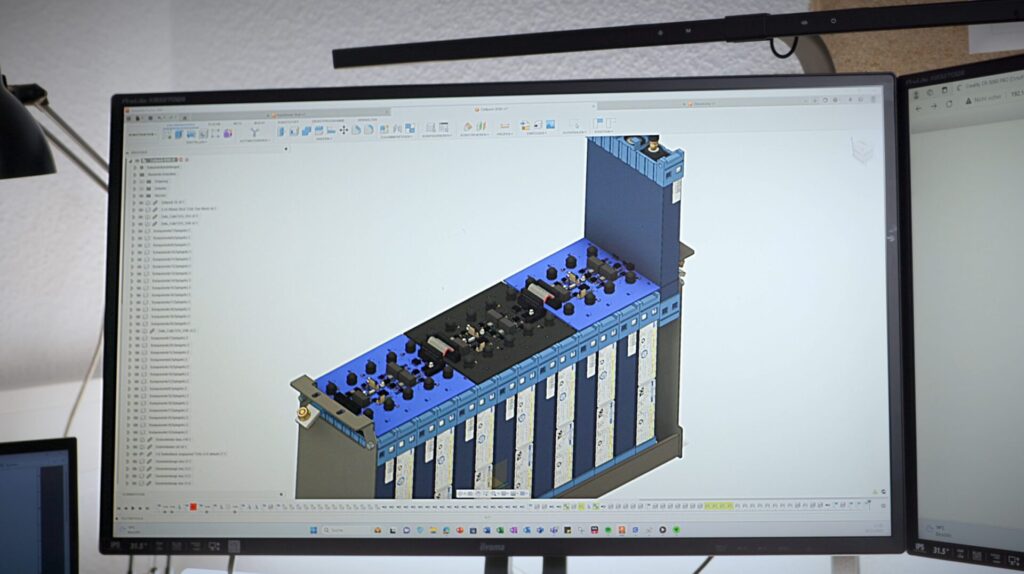

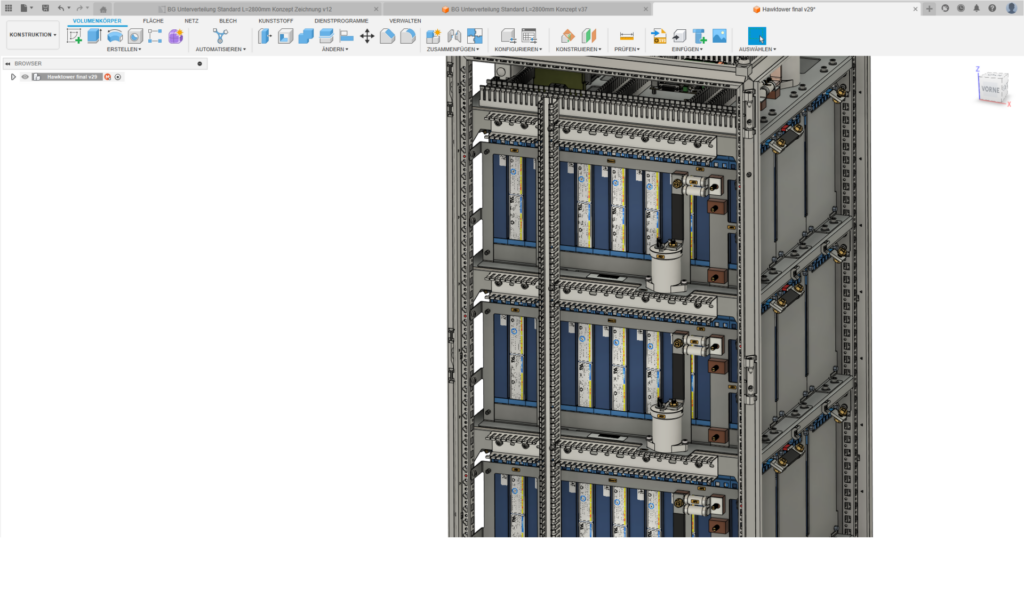

From the beginning, Powertrust has relied on Autodesk Fusion as its product development tool, including when designing its flagship charging tower, the Hawktower. “We started with just an idea and pen and paper,” explains Philipp Schütte, production manager, Powertrust. “We then began designing the system in Fusion, including all the parts we needed for the entire tower.”

Marina Disterhof is a technical drafter at Powertrust. She joined the company about a year ago, but she hadn’t used Fusion before. It didn’t take her long to get up and running with the software.

“Since I worked with other programs before, the change was very easy for me,” she says. “The commands I was familiar with are also available in Fusion and are self-explanatory. Even colleagues who rarely use Fusion quickly learn to use the program because it is very clearly structured.”

Fusion is the backbone for Powertrust’s entire design process, whether it’s individual parts or entire assemblies. Everything is first designed in Fusion and discussed with the team, enabling them to recognize and eliminate problems in advance that may arise later in the production process.

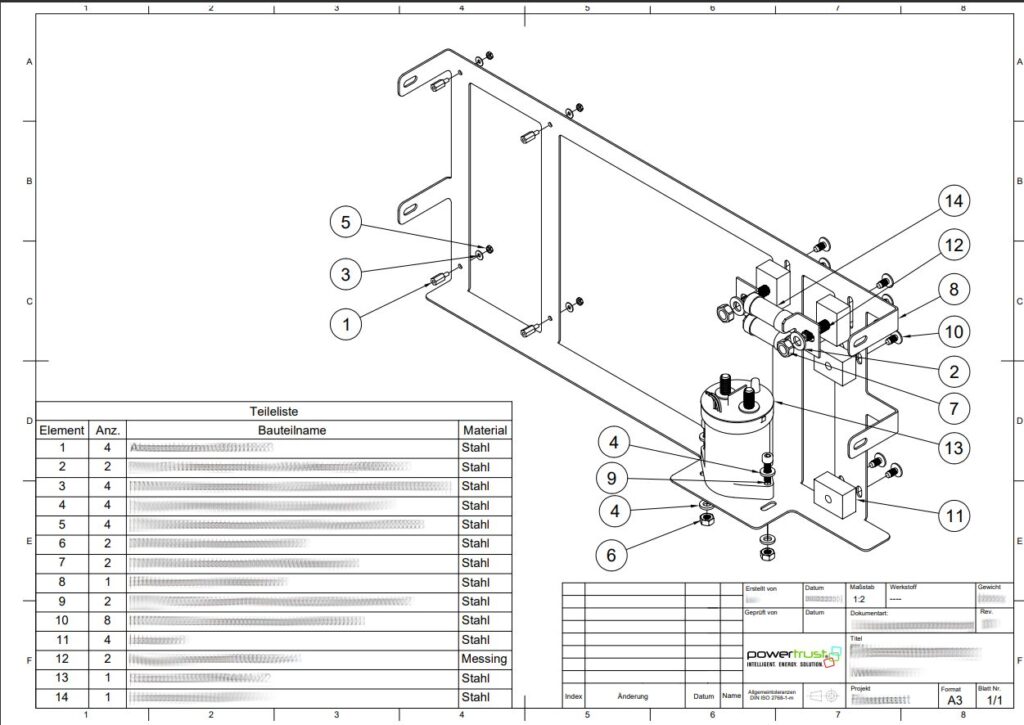

“Once all the components have been designed, I create a technical drawing,” Disterhof says. “We mainly have our parts manufactured externally, and many manufacturers need a drawing. If we want to have plastic parts manufactured, we often print them out on our 3D printer as a prototype before we have a large quantity manufactured. This allows us to fine-tune the design and save time and money.”

For Disterhof, Fusion is key to efficient production and development. When she creates the drawings and parts list, she can easily store the data for each component directly in 3D and view it immediately when needed.

“The more precisely we can design and realize the final design, the more resources and time we save,” she says. “Even for people who can’t visualize the design, we can show it to them in 3D beforehand and they then have a better understanding of it.”

When Powertrust first started, it didn’t have a true manufacturing execution system. In fact, the team initially used multiple Excel spreadsheets for production orders. Now, they’re able to take a digital-first approach to manufacturing.

“When we began using Fusion Operations, it was a really easy transition because we could just import everything from Excel,” Schütte says. “Now we have a better overview of everything and can automatically create production orders and serial numbers.”

Creating serial numbers with Fusion Operations was a pivotal moment for Powertrust. “We have hundreds of parts, sub-components, and raw materials to track for our products,” Schütte says. “Before we only had serial numbers for some main parts. It’s a huge deal for us to have serial numbers attached to everything. We can track everything with Fusion Operations.”

“With the growth of our manufacturing team and using Fusion Operations, we’ve been able to highly improve the number of charging towers manufactured each month.”

—Philipp Schütte, Production Manager, Powertrust

Each day, Schütte checks in with the production team to see how they are doing and what he can change to make their work a bit easier. He also creates production orders, performs quality checks, and is always on the lookout to reduce production times.

“With Fusion Operations, we can track our production time and communicate better with our workers about why they need more time or couldn’t meet an estimated time,” Schütte says. “It provides great insights into our operations and helps us improve our process.”

Moving to tablets at all four working stations has reduced a previously huge amount of paperwork to a single piece of paper. “The employee working in storage can also use the Fusion Operations App on his phone to check all the materials right there,” Schütte adds.

Looking ahead, Schütte is excited to continue optimizing Powertrust’s manufacturing and increasing the footprint of Fusion Operations on its factory floor. “There is more that we’re looking forward to doing with Fusion Operations,” he says. “For anyone looking to increase their efficiency and accuracy, it’s important to take a closer look at Fusion Operations. It makes your daily work much easier.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.