Elevate your design and manufacturing processes with Autodesk Fusion

Explore the intricacies of packaging design and its role in product protection, marketing, and sustainability. Uncover how Autodesk Fusion equips designers with advanced tools for 3D modeling, simulation, and rapid prototyping, streamlining the creation of effective and appealing packaging.

What is packaging design?

Packaging design is one of the most overlooked parts in the product development process. In a crowded marketplace, a product’s packaging can have a huge impact on sales and consumer sentiment concerning product quality, sustainability, and marketing. In this piece, we’ll learn more about packaging design and how Autodesk Fusion supports the packaging design process.

A background on packaging design

Packaging design is the art of enclosing or protecting products for distribution, sale, storage, and use. It involves the development of the external appearance of a product. This includes the selection and application of materials, structural design, and visual elements. These visual elements encompass features like graphics, colors, and fonts on any packaging medium, be it a wrapper, box, bottle, or can.

At its core, the function of packaging design is to provide product protection from the manufacturing stages to final delivery to consumers. This includes safeguarding against physical damage, as well as preventing contamination or deterioration over time. Hence, packaging design must be robust and reliable to withstand the rigors of transportation, handling, and storage. For example, consider the packaging of a smartphone — which often includes a sturdy box, secure fittings to hold the device in place, and additional layers like foam or plastic covers to protect the screen. For smartphones, this kind of packaging is vital for preventing movement that could lead to scratches or internal damage.

Packaging and its role in marketing

Packaging is essential for product protection, and also serves a dual purpose by acting as a critical marketing tool. The packaging appearance plays an important role in influencing purchasing decisions, as it is often the first point of contact with the consumer. Effective packaging design uses colors, typography, and images to create brand recognition and appeal to emotional and psychological consumer needs. This visual and tactile communication strategy helps differentiate a product from its competitors — promoting brand loyalty.

Moreover, environmental considerations are also paramount in packaging design. In today’s market, designers are increasingly opting for materials and processes that minimize environmental impact, reflecting consumer preferences for sustainability. Examples of this include using recyclable materials, reducing packaging layers, and designing for end-of-life disposal or reuse. Additionally, packaging must meet various legal and regulatory requirements that can vary between products and regions.

Leveraging Autodesk Fusion in Packaging Design

Autodesk Fusion helps product designers approach packaging by providing a comprehensive suite of tools that fuse design, engineering, and manufacturing into a single platform.

Free-form modeling

Fusion excels in creating complex, custom 3D models with its free-form modeling tools. Designers can experiment with complex geometries and innovative structures that would be otherwise difficult to conceptualize in 2D format. Develop unique packaging shapes that can capture consumer attention while also optimizing material usage.

Configurations

Configurations allow you to work with a single design file while grouping common aspects of packaging design like material and color. This helps save time when recreating design details and new packaging options.

Simulation

To support these designs, Fusion includes simulation tools that can test designs in virtual conditions — mimicking real-world physical stresses such as weight, pressure, and impact. This ensures that the packaging is practical, robust, and capable to withstand the forces and pressures associated with transportation.

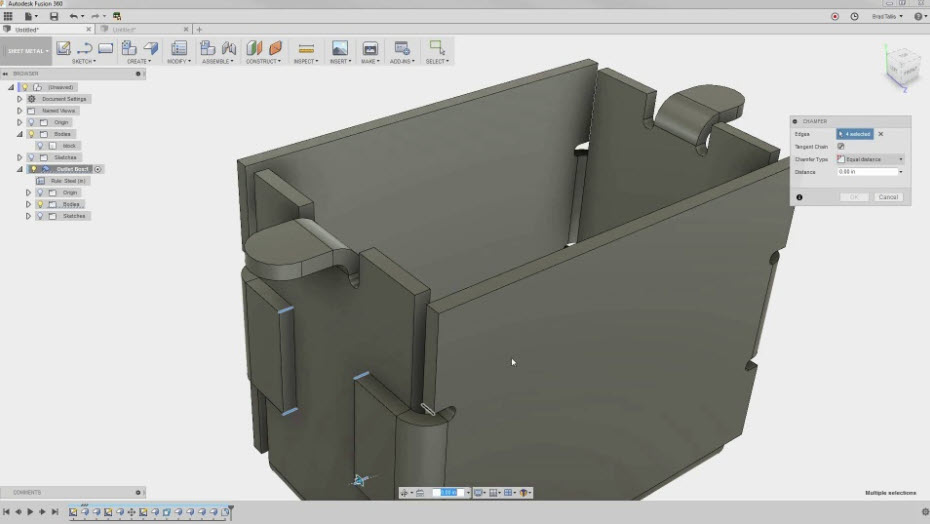

Sheet metal

The sheet metal tools in Fusion are helpful for packaging, transforming flat sheets in 3D parts and vice versa. Designers can create and edit sheet metal components with ease, optimize the design to fit specific product dimensions, and ensure efficient use of materials.

Flat pattern

Designers can quickly convert 3D designs into flat patterns that are ready for cutting and assemby. Fusion can define a product’s material properties and thickness, bending allowances, and corner reliefs — which are all crucial for accurate and functional packaging designs. Fusion also automatically generates the flat pattern layouts necessary for the manufacturing process, streamlining the transition from design to production.

Array/Nesting

Array and Nesting tools are integral to efficient and effective packaging design. The Array tool allows for the creation of multiple instances of a component in a pattern, optimizing the spatial arrangement within a package.

The Nesting tool is used for arranging 2D shapes in the most efficient way possible on a material sheet. This reduces waste with minimal leftover material after cutting, leading to cost savings and promoting sustainability.

Supporting packaging design

Packaging design is a critical component of the product life cycle. It influences everything from product safety and integrity, to marketability and consumer perception. As such, it requires a careful balance of aesthetic design, physical functionality, consumer appeal, and environmental responsibility.

Autodesk Fusion supports this delicate balance by providing a robust platform for designing, analyzing, and manufacturing packaging solutions that are both innovative and functional. With its comprehensive toolset, Fusion enables designers to bring their creative visions to life, ensuring that the final product exceeds market expectations.