& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

Growing up in a small town in New York, Sam Birchenough loved taking components from various devices and making something new out of them. His high school offered college engineering classes where he first learned Autodesk Inventor and the basics of CNC, robotics programming, and prototyping. From that time on, he knew he wanted to pursue product design.

In 2015 with a business and engineering degree from the University of Cincinnati in hand, Birchenough moved to Los Angeles the day he graduated. Once settled in, he started a branding agency with the intent of learning the ins and outs of building a business. As luck would have it, one of his clients at the time was bringing a product to market and needed a prototype. Within a week, BRCHN Design House was born in 2015.

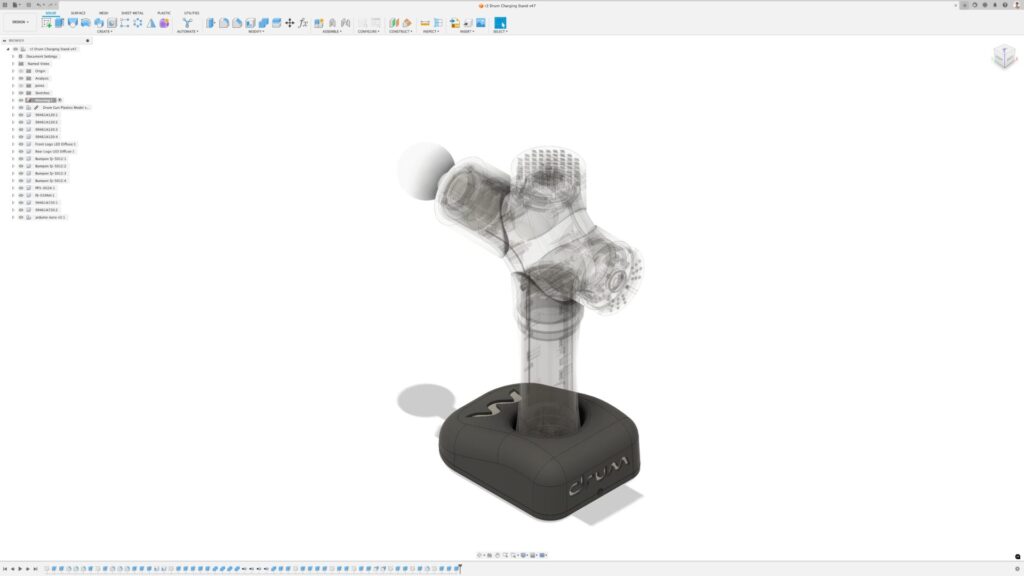

BRCHN Design House was completely bootstrapped. With little capital to speak of, Birchenough started looking at toolsets to build the business and drive his design work. He started using Autodesk Fusion and hasn’t looked back. One of the first things that drew him to Fusion was the top-down design workflow, allowing for a fundamental change in the design process.

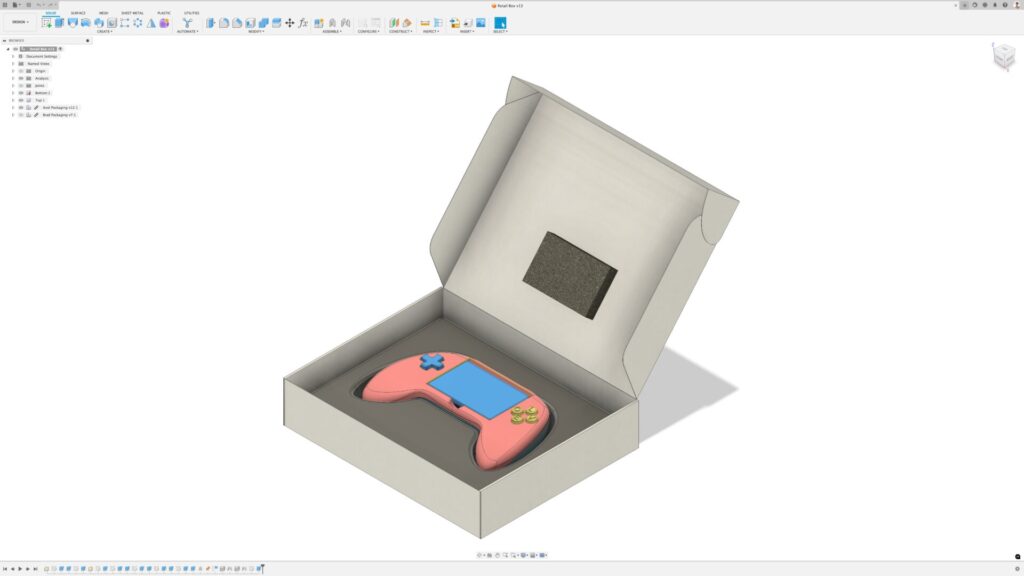

“Fusion is one of the tools we use that has contributed towards our proprietary design process,” he says. “It allows us to skip traditional mood boarding and sketching steps. We create high-level concept models quickly and early in Fusion, which serves as excellent references to get client feedback before increasing the level of details. Say I have housing for a component…I can then split that in half, add draft angles, and make it manufacturable. But I can start with a clay model, so to speak.”

As BRCHN Design House grew, so did the features available with Fusion. The ability to collaborate in Fusion with machine shops and clients alike was an important aspect as he expanded his business. “Being able to share a link with clients so they can view their model in 3D on any device with no prior CAD experience allows me to have really efficient communication with clients relative to sharing 2D screenshots” he says. “They can navigate those models, explode them, and annotate requests. Fusion is a great tool for that.”

“At the time I started my business, picking Fusion was a game-changing decision. From a time perspective, it gave me a substantial advantage over larger firms that were using more traditional CAD software.”

—Sam Birchenough, Founder, BRCHN Design House

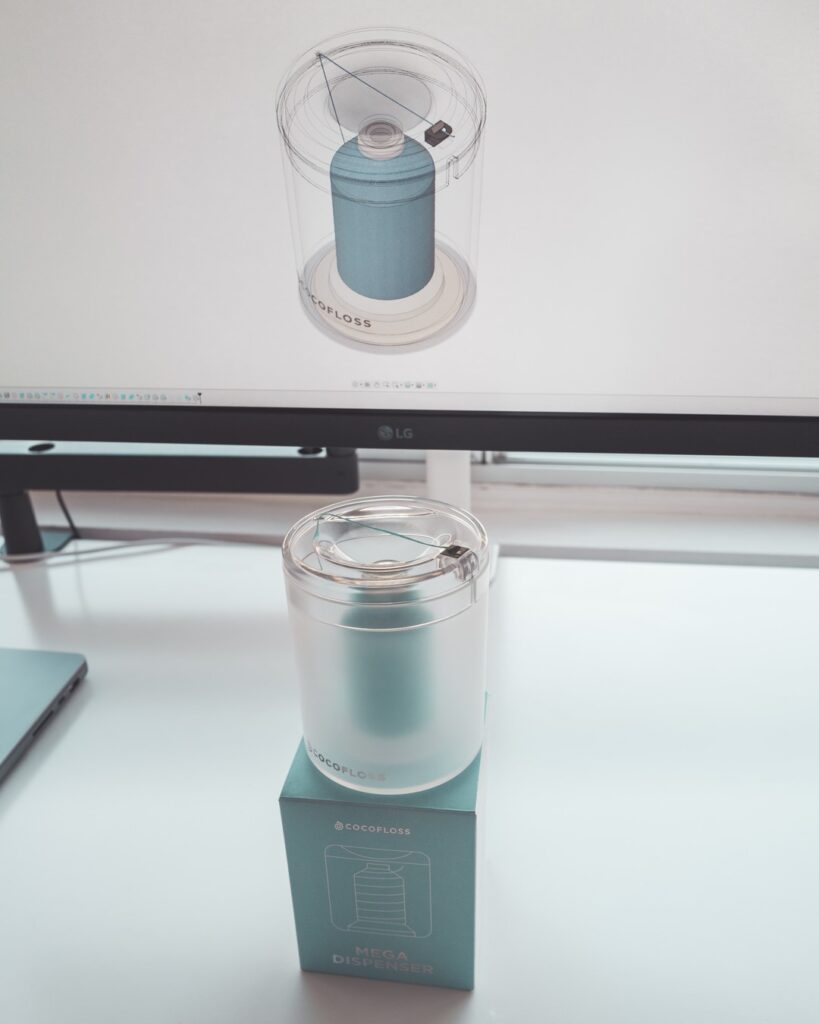

Over the years, Birchenough has delivered more than 70 world-class designs to clients in consumer products, consumer packaged goods, medical, dental, transportation, furniture, and entertainment. One long-time client is Cocofloss, which is innovating new approaches to both home and in-office dental care products. BRCHN Design House has provided five different product designs for the company, including a reusable floss pick and a floss container.

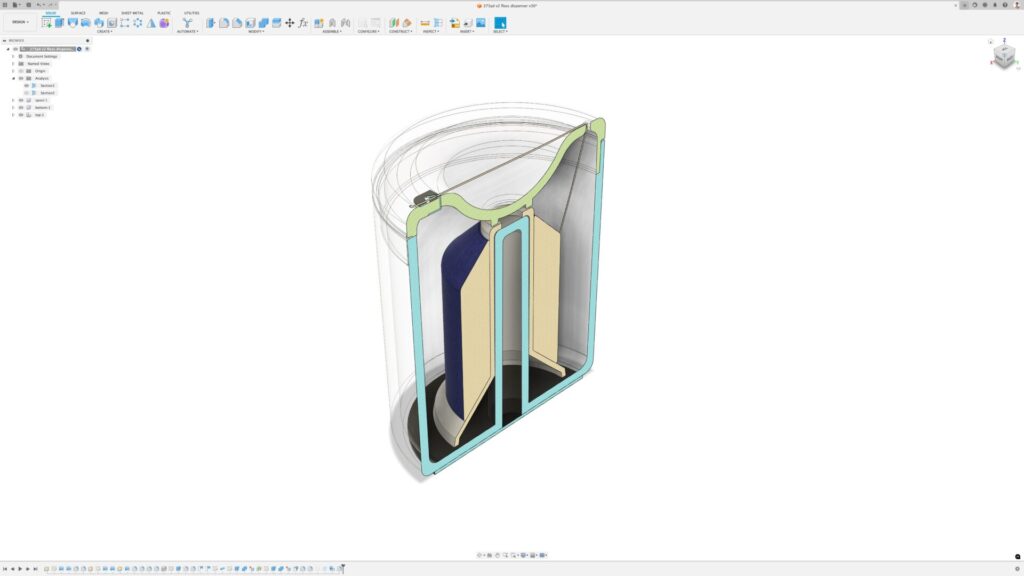

A commercial floss dispenser is also a standout. Cocofloss came to Birchenough with a product requirement list for a 273-yard spool and a few aesthetic ideas. “It’s a cool project because it really is a combination of art and science,” he says. “The dispenser is made to go in dental offices, and it’s a unique design. It’s a product that has really changed the way hygienists and dentists do things in the office.”

Based on their previous work together, he knew the importance of the product family remaining cohesive and in-line with the brand. With Fusion, he created a few high-level concept models. Cocofloss landed on a sculpturally inspired cylinder shape. From there, they moved through a number of digital iterations, supported by physical prototypes used to aid in decision making.

“Once we got in the ballpark of what we thought looked good, I ran an SLA 3D print,” he says. “There’s no substitute for having a physical representation of a product. You can look at models and renders all day, but it’s just not the same, especially since this is where user experience becomes most important.”

Testing of the physical prototypes informed changes to the finger well and the floss cutter design. Birchenough always keeps design-for-manufacturing and design-for-assembly at the forefront of his process. “The dispenser is an injection-molded product. The constraints of the process, such as uniform wall thickness, places for ejector pins, and correct draft angles were considered from the beginning,” he says. “That way it doesn’t require a redesign when you transition to volume production.”

As word-of-mouth and repeat business have continued to grow, Birchenough is beginning to move the business in a new direction so he can simultaneously pursue his personal product designs. Now, he offers four client design slots per month that are always filled very quickly.

“My ultimate goal is to create my own products that make the world a better place,” he says. “I’m currently working on a capacitive touch, smart light switch that I may bring to market. I want to be in a position to capitalize on ideas when I have them. You can’t really force creativity, and I know from experience what it takes to build a business and the investment.”

For others thinking about pursuing their own entrepreneurial path, he shares these words of advice. “If it’s for you, you’ll know it and you’ll make it happen. Certainly, it’s important to make more good decisions than bad ones. And part of that is learning the right skills and choosing the right tool sets. In my case, that’s Fusion.”

Birchenough recently joined our podcast, Shop Talk, as a guest to speak more in-depth about his design approach. Check out the full episode below:

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.