& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

7 min read

About eight years ago, Zenbooth founder Sam Johnson enjoyed the many benefits of a co-working environment—but not the huge downside of all the noise and distractions that went with it. The privacy pods were often stuffy and lacked good soundproofing. From his own uncomfortable experiences, he knew he could design and make a better booth solution and embarked on a new design journey—even with zero experience in design, woodworking, or manufacturing.

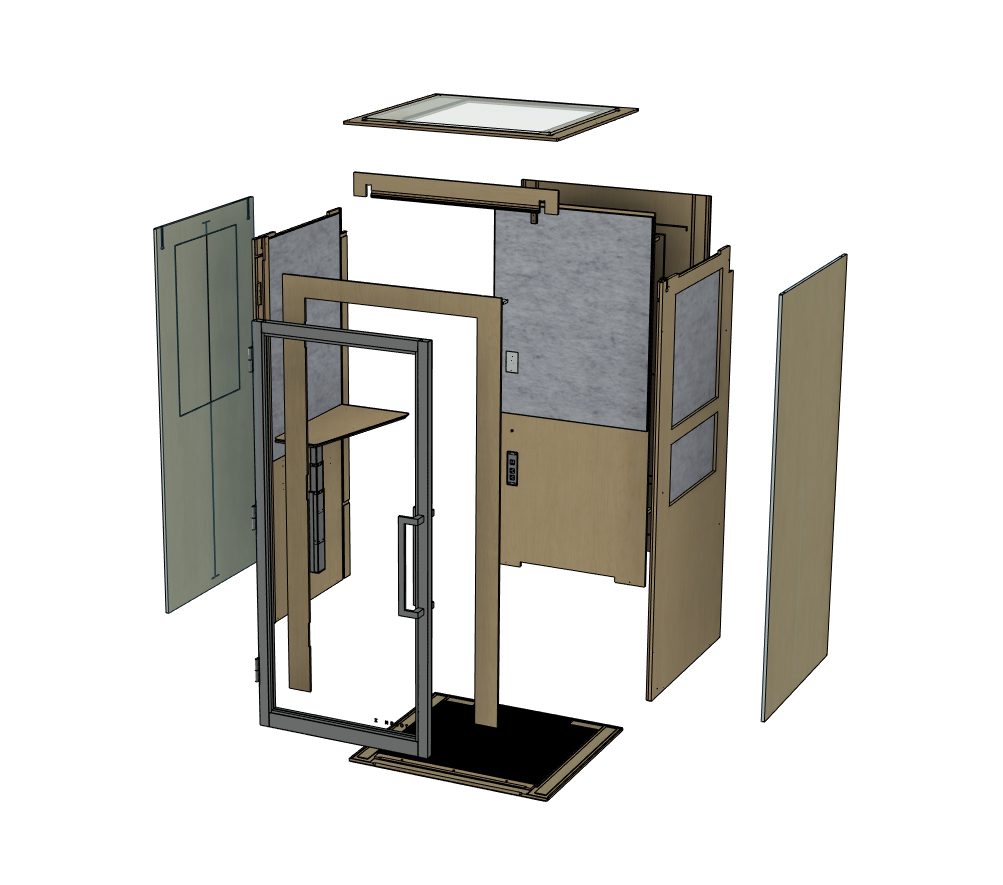

From day one, Johnson started learning Autodesk Fusion from scratch. His first ideas for a privacy pod were made as parametric models. Constant learning, prototyping, and building a team of skilled designers led to 18 versions of its flagship product Solo between 2016 and 2019. Each new version incorporated lessons learned from the previous one, gradually refining the design and functionality. Zenbooth became the first company to manufacture a “flat-pack” privacy pod that people could build in their office and is now a market leader in delivering a wide range of eco-friendly privacy products for offices.

Now including advanced soundproofing, a ventilation system to ensure a continuous flow of fresh air and use of wood as a sustainable alternative to metal or fiberglass, Zenbooth provides truly unique solutions for a quiet place of focus and communications.

“From the very beginning, we’ve used Autodesk Fusion. It was very affordable for us as an early start up. As time went on, Fusion seemed to be similarly minded to us and what we could start using, from parametric modeling to rendering and the Manufacturing Extension. Even the animation workspace has helped generate our instruction booklets so customers have comprehensive assembly instructions. It’s cool that Fusion has just grown with us.”

—David Evans, Head of Product, Zenbooth

With offices and a factory based in Berkeley, California, and 20 employees, Zenbooth offers eight privacy pod models in three sizes with various color and feature differences and a number of other products used in commercial office spaces. Continuous improvements to Fusion have helped streamline Zenbooth’s design and manufacturing processes as the company has grown, especially in creating a more streamlined CAD and CAM workflow that has significantly reduced the time required to update production files.

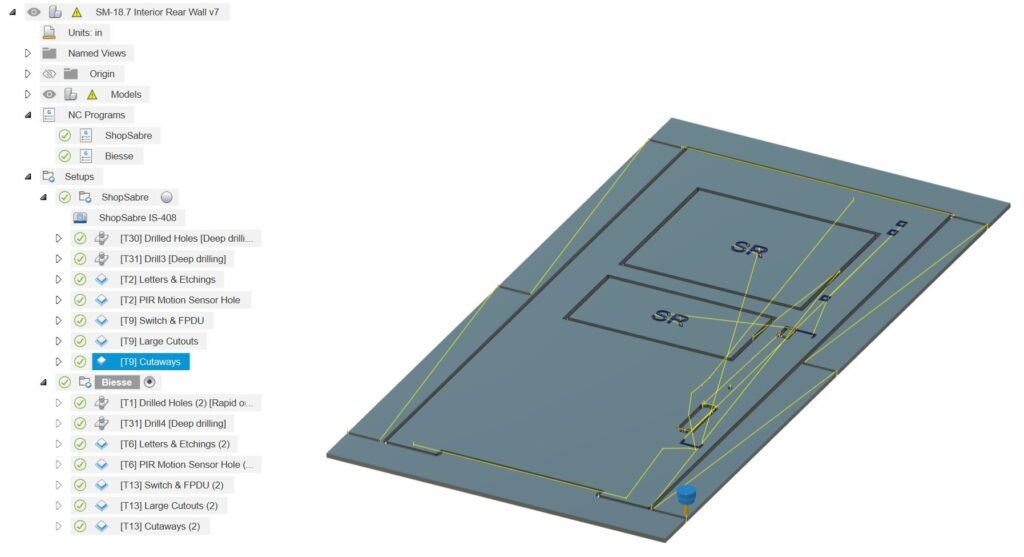

“We have multiple processors loaded into Fusion and a single tool library,” says David Evans, Head of Product, Zenbooth. “If we designed a product to be cut on one of our machines and then brought it to the production machine, it used to take a week to redo the CAD and CAM. With the Fusion Manufacturing Extension, it’s just a few button pushes, and we can push CAM changes to multiple machines.”

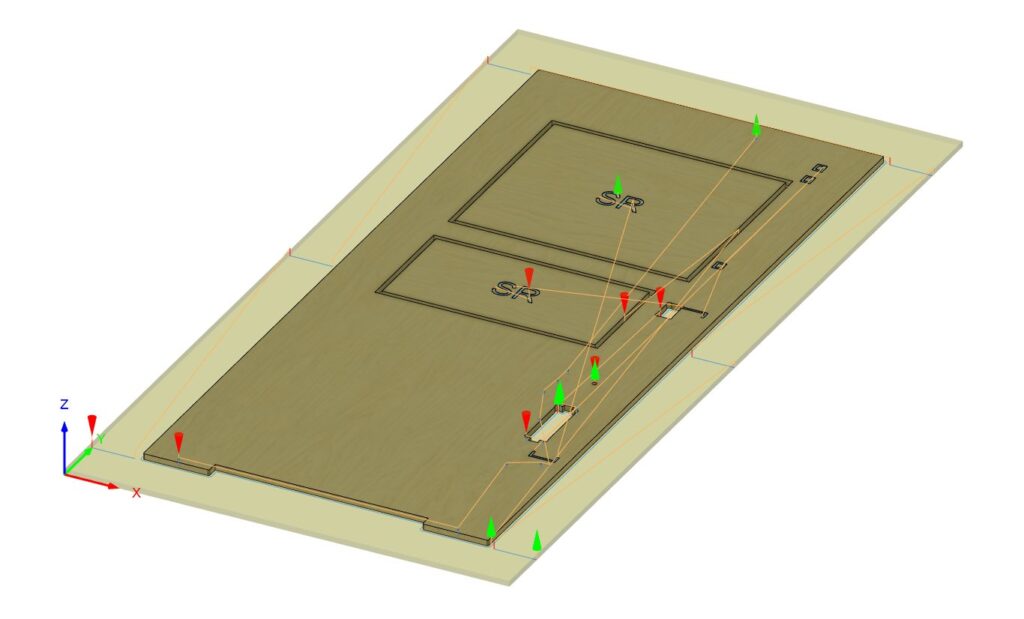

According to Evans, a stand-out aspect of Fusion is its strong joint capabilities. A key example is the use of rising hinges, which they prototyped with Fusions’ joint and sheet metal tools to ensure the doorframes accommodated the rising movement.

“The jointing feature is really strong and easy to use in Fusion and it’s one of the things that makes Fusion our preferred program over SolidWorks,” Evans says. “With Fusion, I could easily model the rising hinge which allowed me to perfectly design a doorframe that fits the door without any extra space around it. It was a fun project, and something I think is unique to Fusion’s capabilities that would have been harder in other CAD programs.”

Fusion has enabled an increase in prototyping, custom work, and product modifications for Zenbooth. Even back during the pandemic, rapid prototyping was critical. The company quickly pivoted and developed a modular sneeze guard brand to rapidly deploy hundreds of sneeze guards to local hospitals around the Bay Area. By using Fusion and parametric models, they could resize the components into hundreds of different configurations and almost automatically generate renders and drawings for the hospital facilities staff to approve. Then their existing local installation network was repurposed to install the guards instead of their office pods. “Fusion was a key tool in being able to deploy this service during the pandemic,” Evans says.

In the years since the pandemic, the rapid prototyping process has been vital for their new products and research and development. The team can change the entire size of the product to scale up or down and get it to perform the way it wants. They can even focus on individual components and files which makes it easier for engineers to make small changes if they need to move screw holes or widen dowels.

“Streamlining our R&D process pushed us to use Fusion even further and made us dependent on it in a good way,” Evans says. “We can just crank out revisions much more quickly and do renders if marketing wants to look at different sizing or wants to try walnut versus another wood type. Rendering in Fusion means we don’t have to build the physical prototypes and can save a lot of money when making decisions about fit, finish, and general proportions.”

On the manufacturing side, Zenbooth has also taken a technology-first approach to streamline and improve its manufacturing processes and operations. By 2019, their use of Airtable had hit a wall with inventory control. It was time to find another answer. However, the team quickly found that many solutions on the market would require a huge, expensive time investment to get started.

“We were really looking for something that would help us easily manage the inventory, production line, and team’s time so we could better understand where everything was going,” Evans says. “We evaluated 33 different ERP vendors. From the get-go, I saw that Autodesk Fusion Operations was designed around timing. We all needed this missing link, and it was a really good fit for us.”

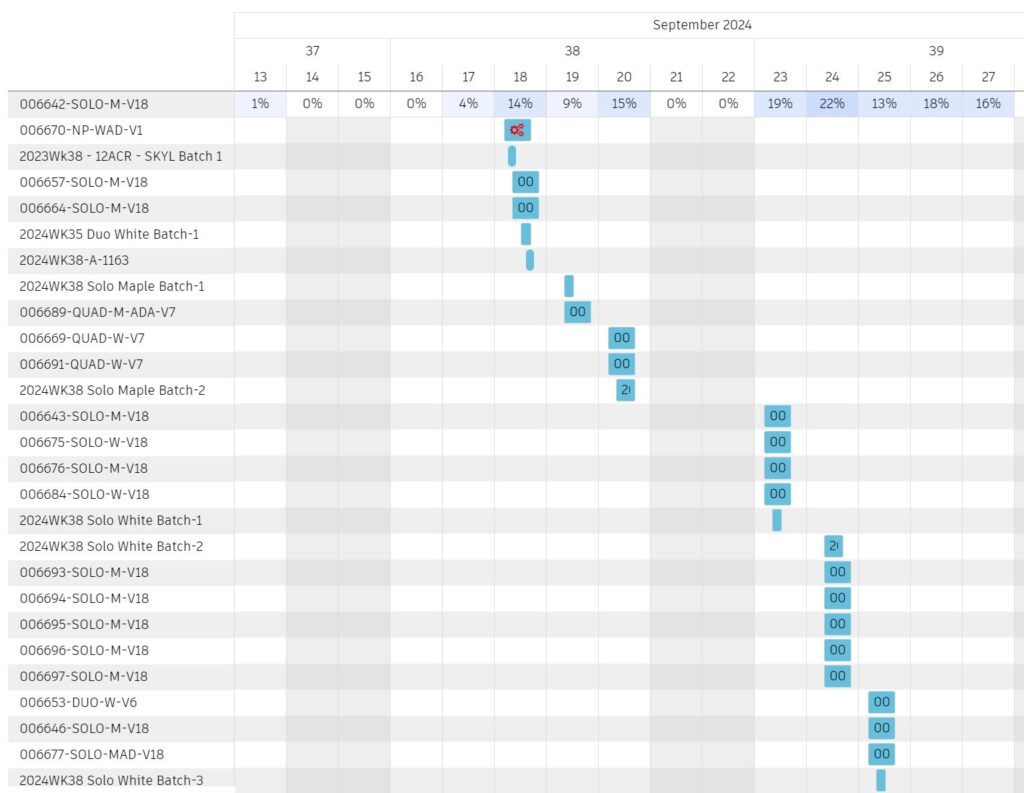

Inventory management and lead times were a constant challenge for Zenbooth—especially post-pandemic with the disrupted supply chain. They set a goal to have the lowest lead time for a privacy pod manufactured in the U.S. In Zenbooth’s first implementation of Fusion Operations, they directly integrated their sales order queue from Shopify and converted the sales orders to production orders. The visibility gained from the increased granularity of order-specific production dates helped reduce lead times from 90-120 days to 40 days, translating to a 55-67% efficiency gain.

“With Fusion Operations, I got very accurate answers on our lead times and there was no longer this mysterious vacuum of production or shipping dates,” says Sean Gaffney, Operations Manager, Zenbooth. “This was a huge problem we were trying to solve with the software, and it did the job beautifully. It’s very precise.”

Transparency and quality control have also dramatically increased with Fusion Operations by using the lot number feature. Zenbooth can now record each production order when the production team will produce it, and what materials will be used in its making. This number is also transferred over to the sales order in the shipping module.

The team can see which customers received a specific product along with the data about who worked on it and when. If there’s ever a quality control issue, they can immediately identify it and address the manufacturing processes for future production.

“Lead times and communications are a big deal when it comes to someone choosing us versus one of our competitors. We are a small, American-made business, and we pride ourselves on making such a great product. Fusion Operations has made such a huge difference not only for us, but also for our customers’ experience with Zenbooth. Happy customers are the most important thing, and Fusion Operations helps us achieve that.”

—Bex Hartke, Head of Sales and Marketing, Zenbooth

Short lead times and communications are a critical competitive differentiator for Zenbooth. Delivering a product quickly and efficiently delivers a better customer experience that helps the company stand out from the rest.

With Fusion Operations, production, logistics, and shipment are seamlessly tied together for every single order. Inventory is kept in check with visibility of what is being used in real-time. The shipping department can also click a single button that sends an advanced shipping notice integrated into their Shopify implementation, triggering an email communication to the customer that the order is on the way with a tracking number.

“It may sound like such a simple integration, but it has made a huge difference on the customer support side and for shipping or status updates,” says Bex Hartke, Head of Sales and Marketing, Zenbooth. “Fusion Operations has helped us dramatically decrease the number of customer support requests. Being able to push a button that automatically sends the order status not only reduces the amount of admin cleanup, but it also just makes our customers’ experience so much better. Fusion Operations has made our lives way easier.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.