& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

10 min read

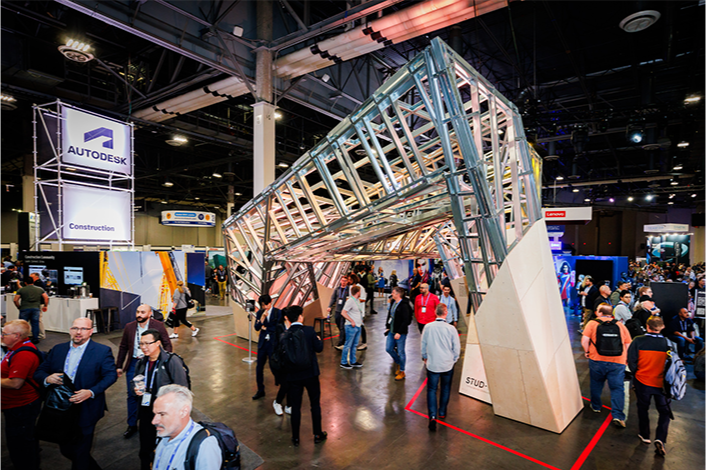

In this compelling panel conversation that took place at Autodesk University 2024, Srinath Jonnalagadda, VP of Industry Strategy for Design & Manufacturing at Autodesk sat down with three distinguished industry leaders from Kia Motors, Kennametal, and Bridgestone to discuss the future of design and manufacturing.

Watch the full panel here, and read the transcript below.

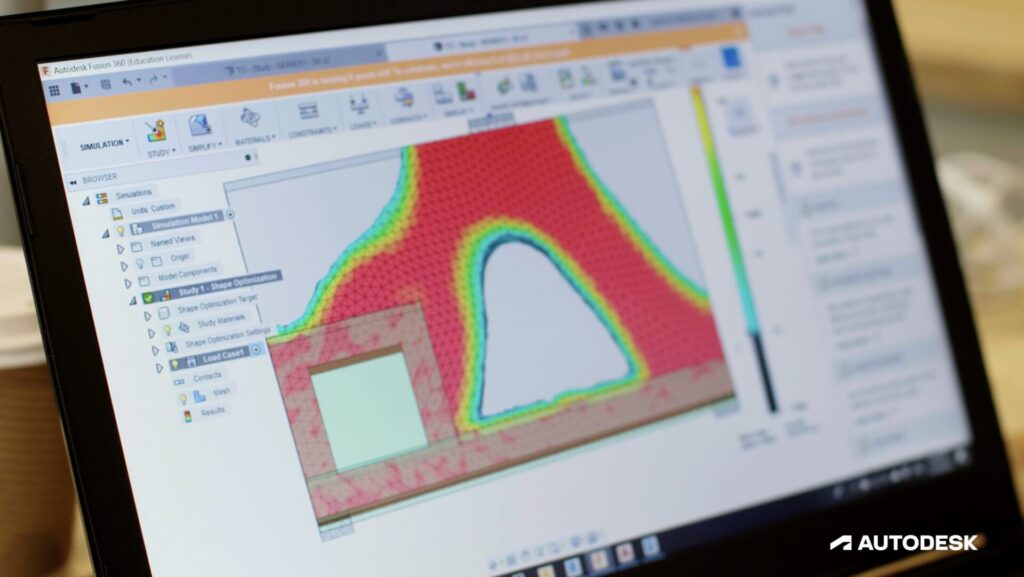

Dr Carlonda Reilly, Chief Technology Officer at Kennametal: Part of our vision for digital transformation is to automate pre-manufacturing steps in the production of industrial parts or components and to make that automated process a widely available, “easy-to-use” experience for customers. In a typical manufacturing value chain, tool data exists in silos and must be shared manually—with customer CAM programmers and throughout the value chain. The inefficiencies can lead to various issues, such as initial tool breakage, poor part quality and very frustrated operators, etc. So, we want to eliminate the silos and integrate tooling know-how, tool data, Fusion software and machines. So, the data would flow throughout the value chain, optimizing manufacturing paths automatically, and making it possible to produce the part right the first time.

Andy Warren, Senior Manager for Engineering Services at Bridgestone: Like Carlonda said, we also need to remove those data silos that slow us down. Our own digital transformation has stemmed from a variety of industry factors to optimize our operations. We have to run our factories 24/7 because, well, rubber doesn’t like to get cold! With that round-the-clock production, we need to hit new operational efficiencies, especially as we face huge labor shortages. The digital transformation for our smart factory really covers everything from the actual built environment to the machinery, plant layout, and everything in between. Our transformation is not a sudden overhaul but a series of incremental improvements leveraging technology to meet market demands and sustainability goals.

Voho Seo: I believe digital transformation is crucial for everyone—especially in the design field, One of the biggest advantages is being able to archive data from past projects and leverage it for future ones. Accessing datasets and finding references that fit our specific situation is a huge benefit. This makes our jobs easier and keeps consistency in our work. The way we work is going to be different from it is now, and these data sets will play a crucial role. They will be more than references. They will be assets to train AI to understand our workflow. Knowledge transfer is key to using AI effectively across industries. Think of AI as a new team member. It needs training. Without our own data sets, it’s going to be tough to train it properly. For us, especially in the mobility industry, data security is crucial and that’s why it’s important that AI systems are built and trained based on our own data sets.

Voho Seo, Lead AI Designer at Kia Motors: In design, there’s no single correct answer. That’s why designers go back and forth, exploring different ideas and navigating the uncertainty that comes with it. We saw opportunities with AI. Could AI break the idea fixation and amplify designers’ creativity? With this question in mind, we started looking for a research partner who understood both AI and design. And we were luckily able to start a year-long research collaboration with the Autodesk Research Team. We learned a lot from this experience, and I’d like to share three key things. First, introducing AI is like onboarding a team member. You can’t hand them a job and expect them to get it right away. We need to fully understand how our processes work so we can figure out how to transfer the knowledge to the AI. We also had to spend time and effort figuring out what our design process was like and the knowledge behind it. Second, to team with AI, understanding its strength is also crucial. What’s remarkable here is both AI and designers use texts and images to create something new. Designers gather inspiration from images and express them with adjective keywords, while AI uses similar inputs to generate new images. This means AI can mirror the way designers work, so by feeding specific images, we can guide AI to generate what we’re looking for instead of generating random images. Finally, human insights remain to be our most competitive value in the age of AI. We can’t let AI decide everything. Tasks like establishing and nurturing brand value and design philosophy should be done by humans. But AI can be a great partner alongside us to make the process smoother and faster. There are still a lot of things to do, but we’re excited about what’s next with our strong partnership with Autodesk.

Dr Carlonda Reilly: AI will give us the ability to fulfill our ultimate vision of making the part “right the first time.” We have ways to go, but with more digital data available through Fusion, we will be able to build a “learned” digital eco-system that can be accessed by all our machining customers. And in particular, small and medium job shops who might need to rely more and more on this capability.

Dr Carlonda Reilly: Kennametal has been on its own digital transformation in manufacturing for several years. We work on design automation and digital data and utilize CAM in our own processes to make our innovative tools in the most efficient way. Because we are integrating our tool data with Fusion, we can also bring the best tooling and manufacturing solutions to our customers as well. I think we all have heard about the growing trend in the manufacturing industry where experienced programmers and operators are retiring. The loss of this know-how is resulting in a growing skills gap within the industry. We believe this trend will have more impact within small and medium job shops, which rely heavily on external tooling expertise like Kennametal provides. So, we are asking ourselves—how can we extend our technical reach to effectively support these customers? Our vision is for our customers to have easy access to an automated eco-system where our tool data is integrated with Fusion, and through our Collaboration Space, customers not only can access our advice for the best tooling solutions, but they also will be able to access the best machining strategy to do their job. So young (and old), less experienced engineers and operators can gain access to all the knowledge and information they need to manufacture products faster, and more cost-effectively.

Andy, you also mentioned earlier that labor shortages are a major factor in Bridgestone’s digital transformation. Can you tell us more about how you’re tackling that challenge?

Andy Warren: We’re using Fusion Manage to standardize how we do engineering across Bridgestone, and that’s going to be our tool to help drive engineering for the next generation by taking the engineering workflow and automating it into a system. So, somebody who’s been here two weeks can follow the same steps and access the same data as someone who’s been here 20 to 25 years. They know the steps too, and we can use that to address the knowledge gap and help us with the wonderful benefits of going to 3D.

Andy Warren: Funny story, I was hired 13 years ago to come in to set up Vault, and I thought six weeks later I was going to work myself out of a job. 13 years later we’re realizing that we don’t need to just change to a new data management tool but change how we work. We’re moving to the next generation of engineering for a smart factory with the tools to help get us to that digital twin. That means working across disciplines. Our group specializes in the machines that make the tires, and we need to keep that information from concept through 50 years of operation on that piece of machinery. With Fusion Manage, we’re rolling out an asset-tracking tool where we can keep track of all the changes that happen to our machinery over time. But we also need a holistic approach to the factory itself. We build buildings to keep our equipment dry. Now, our machinery’s huge. It could be 300′, 400′ long, 6 stories tall, 50 to 100 feet wide, and that’s just one piece of machinery. So, we must be smart about how we do it. With BIM, we can all visualize and communicate about the building. We can see if there will be a clash with the machine and, say, the ceiling height. At the same time, we can use all this data to create a digital twin that will make a massive impact on data and insights for our factory operations.

Really incredible. All three of you are such change agents in design and make. As everyone here today moves forward with their own digital transformations, what advice would you leave them with? Voho, let’s start with you.

Voho Seo: I think we need a realistic view of AI. It can’t help with everything, so we must strike a balance of expectations. And the most important thing for all of these is experience. I really would like to suggest everyone dive into this big wave of technology. Until you experience it yourself, you might not be able to understand it. There was an interesting statistic regarding the use of AI. The time people spend on Gen AI apps such as ChatGPT pales in comparison to other online services, such as search engines or entertainment platforms. This means there are a lot of things people can do with AI, but many of them are having trouble making better use of it in the real world. We’re at the tip of the iceberg with AI and need to think about the long-term gains. This is a marathon—not a sprint. We’re going to see massive changes depending on how we use it and how we interact with it.

Dr Carlonda Reilly: Make sure you know what challenge you are trying to solve that truly addresses the need or the emerging needs of the customer. There are many aspects of digital transformation that are fun to explore, but our business is about helping our customers solve their toughest challenges so they can machine what they need to machine right the first time. We at Kennametal are excited to be pursuing this vision in partnership with Autodesk.

Andy Warren: What’s key is finding out where you can connect your different systems. How that data travels through that digital model is what makes that happen. You’ll really find the value when you can get that data to travel through to improve your communication, which reduces change. Sharing both the good and bad experiences is important. “Hey, this worked really well, let’s do this instead now.” Data is the way we do that. As a data-driven company, it is important the way you capture, track and share data.

Want access to more insightful Autodesk University content? Watch free on-demand industry talks and courses here:

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.