Autodesk and SCANLAB have collaborated to create a real-time closed-loop control system for laser powder bed fusion processes, integrating SCANLAB’s advanced laser control systems with Autodesk’s Fusion software, significantly enhancing precision and efficiency in additive manufacturing.

At the heart of many industrial 3D printers, particularly those used for processing metals, are high-powered lasers moving at incredible speeds to melt or sinter powdered material with precision. The demands of this process—combining high power with exceptional accuracy and rapid response times—push the boundaries of modern science and engineering.

Achieving closed-loop control, where the system continuously monitors the process temperature and adjusts the laser’s operation, has long been a challenging goal in laser-based manufacturing. Despite decades of effort, hardware manufacturers have struggled to fully realize this capability.

SCANLAB and Autodesk team up to enable real-time control for laser powder bed fusion processes

SCANLAB GmbH is a global leader and independent OEM in laser beam deflection and positioning solutions, produces over 40,000 high-performance systems annually. Their galvanometer scanners are trusted across diverse industries. These include industrial material processing, electronics, food and beverage technologies, automotive and aerospace engineering, and, notably, additive manufacturing.

Through the integration of SCANLAB’s advanced laser control systems with Autodesk’s Fusion software stack, research labs and machine tool builders now have access to a complete, real-time closed-loop solution as standardized, off-the-shelf component.

For the first time, precision-controlled process management is within reach for any machine tool manufacturer. This eliminates the need for costly R&D investments and accelerating innovation across the industry.

Precision path planning for industrial laser processes

Just as path planning is essential for CNC controllers in 5-axis machining, accounting for mirror inertia is a critical factor for achieving precision in industrial laser processes.

SCANLAB’s SCANmotionControl software is a standout solution in the market. It offers the unique capability to pre-calculate optimal trajectories based on specified machining patterns and process parameters—all while operating within the physical constraints of the hardware.

For example, users can define corner tolerance to achieve precise rounding or maintain a constant processing speed. Additionally, minimum and maximum process speeds can be set, optimizing laser-off times and eliminating the need for time-intensive manual adjustments,. This ultimately ensures consistent, high-quality results.

With 34 years of expertise, SCANLAB delivers unparalleled accuracy, predicting laser beam movements with timing precision down to 10 microseconds and spatial accuracy within the micrometer range. These advanced capabilities are essential for advancing towards the vision of “industrialized additive manufacturing,” which holds the potential to revolutionize traditional manufacturing methods.

SCANmotionControl integrated with Autodesk Fusion

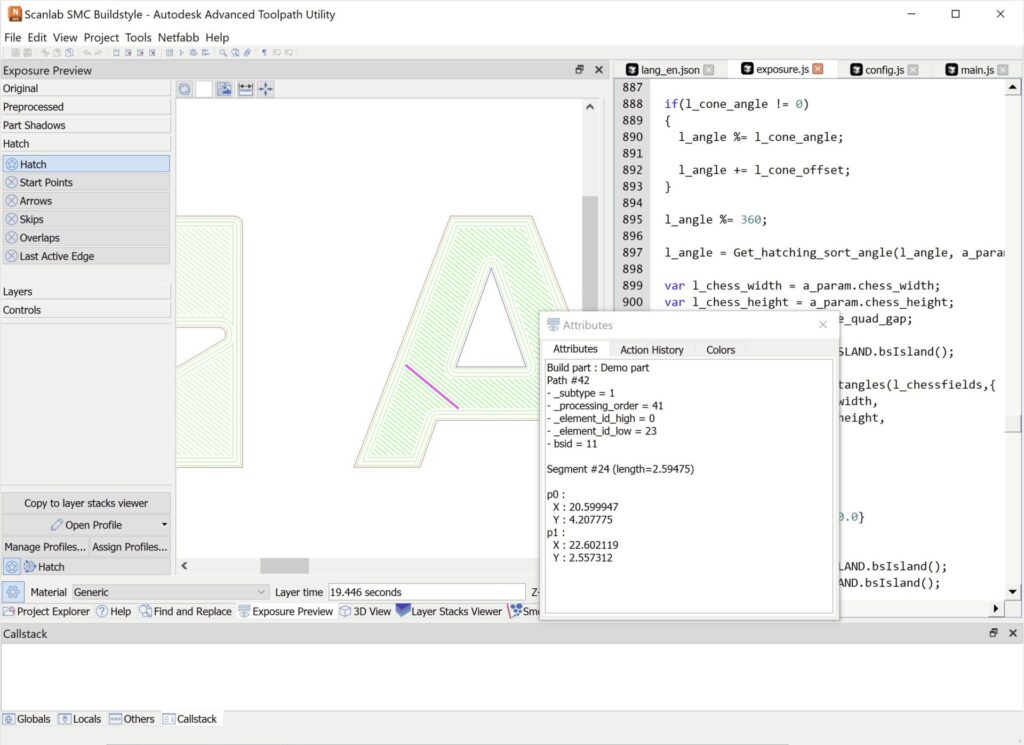

The integration of SCANLAB’s systems with Autodesk Fusion and Autodesk Netfabb allows simulation and control capabilities to be parameterized and customized directly from the CAD toolchain.

Autodesk’s state-of-the-art toolpathing kernels provide developers with unparalleled control over laser operations, enabling hatch-level precision and microsecond-level timing. Key features include:

- A powerful JavaScript-based scripting environment for developing custom laser toolpath strategies

- Angle-range-specific upskin and downskin laser parameters for enhanced surface quality

- CAD-driven toolpathing with volumetric power variation for optimal energy distribution

- Advanced hatching strategies, including custom infill structures, hull-core strategies, and specialized applications for niche manufacturing needs

- Real-time synchronization for up to 32 lasers with on-the-fly marking capabilities

- Intelligent multi-laser efficiency to maximize return on capital investment

- Full parametrization of beam shaping parameters, compatible with hardware like nLight AFX lasers.

- The ability to replicate proprietary toolpathing behaviors from machine OEMs, while maintaining compatible material profile settings to avoid costly requalification of process parameters

It is impossible to fully outline the extent of these capabilities in a single blog post, but the leap compared to the current state of the industry is truly transformative. And as a consequence, the Advanced Toolpath Utility has proven to be very popular in Academia and Industrial Research alike.

With Autodesk’s support, SCANLAB has leveraged this powerful toolchain to develop and open-source example code for a specialized toolpathing kernel. This kernel highlights the advanced features of SCANmotionControl and establishes a seamless connection between the CAD environment and the hardware controller, effectively bridging the gap between design and the manufacturing process.

The Autodesk Fusion ecosystem for laser powder bed fusion

This code can now can be published within minutes to a mass market CAD platform like Autodesk Fusion, which boasts millions of users. This accessibility significantly reduces the time required to transition from laboratory-stage development to production-ready systems. Thus dramatically accelerating innovation and enhancing the competitiveness of machine tool manufacturers.

But it’s not just about toolpathing. Integration into a broader parametric CAD environment, along with features like PLM data management, FEA simulation, and CNC postprocessing, is essential for any solution to achieve widespread adoption. Autodesk Fusion delivers all of these capabilities seamlessly. It offers a comprehensive solution at an exceptionally competitive price point—an almost negligible addition to any machine vendor’s financial planning.

Temperature control with process simulation for laser powder bed fusion

Thermal control remains one of the key challenges in process management for laser powder bed fusion additive manufacturing. Insufficient melting temperatures can result in incomplete fusion, while excessive laser power can cause keyholing. This leads to increased porosity and reduced part quality.

Autodesk Fusion, equipped with the industry’s most validated FEA process simulation solver, provides an ideal platform to address these challenges. This setup enables simulation-driven, upfront adjustments to laser power across the entire volume, ensuring consistent thermal performance and improved process reliability.

While simulation-based power optimization is great to mitigate global issues like part distortion and temperature buildups, it has its limitations. For example, local defects like corner hotspots and overhang surface quality are expensive or impossible to resolve.

Emerging developments in physics-based AI surrogate modeling for process simulation are moving those limitations quite a magnitude. However, this is also where an in situ, closed-loop approach to power control becomes highly complementary. Even if used solely for monitoring or constraining the process to its digital twin, real-time adjustments can significantly enhance precision and ensure a closer alignment between the physical and simulated processes.

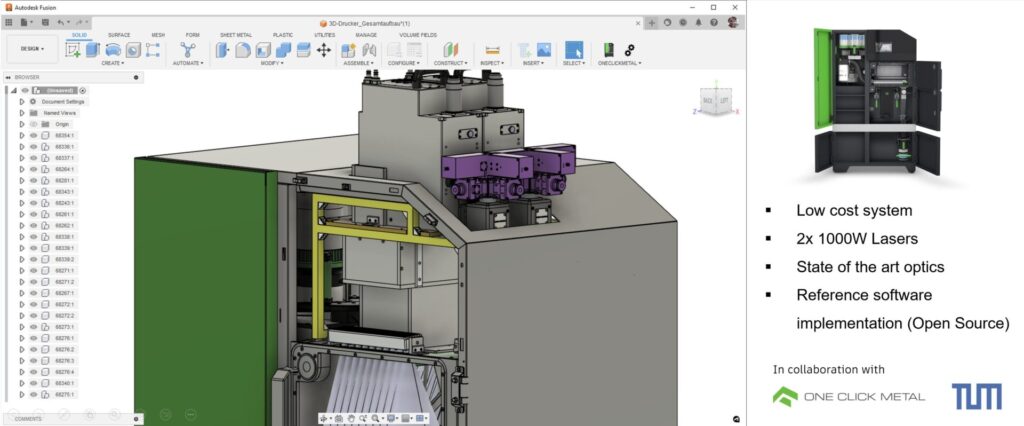

Demonstrator platform based on a mass-market machine

To be credible, even the most compelling software architecture is incomplete without a robust hardware proof of concept. To address this, SCANLAB funded the development of a Technology Demonstrator in collaboration with the Technical University of Munich. This demonstrator retrofits a commercial-grade, off-the-shelf machine with cutting-edge scanning and laser technologies, including SCANLAB’s fiberSYS, SCANmotionControl, and Open Interface Extension.

Built on the exceptionally compact and robust mass-market MPRINT system from One Click Metal, the demonstrator has achieved remarkable results. The machine has been upgraded with two cutting-edge fiberSYS heads, supporting dual 1000-watt lasers from IPG Photonics, along with a two-color pyrometer from Sensortherm. Together with SCANLAB’s advanced real-time control electronics, this setup enables the system to react to melt pool temperature changes within just a few microseconds.

All hardware components are seamlessly integrated with Autodesk’s Machine Control Framework, which provides direct, end-to-end connectivity with the Autodesk Fusion ecosystem. Thanks to the industrial-grade quality of the hardware and software, the integration process required only a few weeks of part-time engineering effort to produce the first parts with precisely controlled laser power.

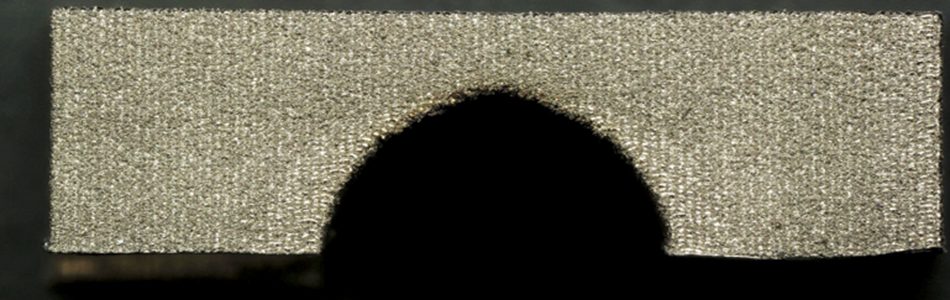

Enabling a 50kHz real-time PID control on the laser output has significantly enhanced the visual quality of parts, particularly in overhangs and other complex regions.

Research collaborations for laser powder based fusion

To scale this approach, SCANLAB engaged with several other research institutes, whose contributions are described in the following sections. These collaborations focused on testing and extending the methodology to address broader application needs.

Hochschule Aalen

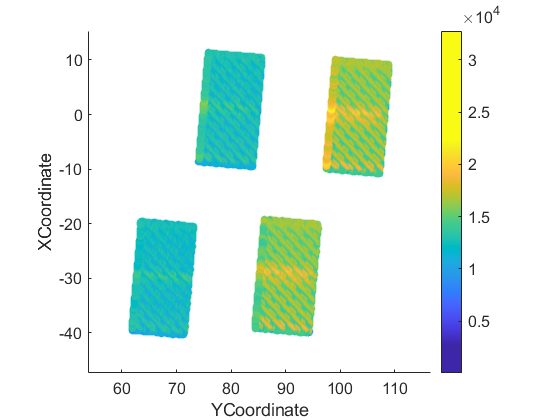

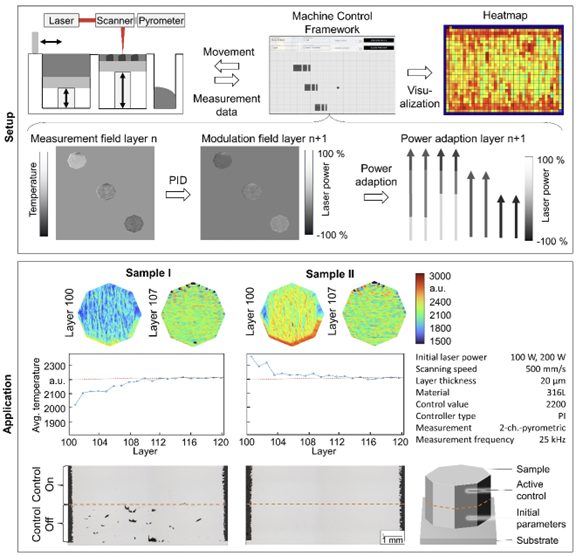

At the Laser Application Center (LAZ) of Aalen University, a modular 3D printing platform was developed to enable temperature-controlled process management for Laser Powder Bed Fusion (L-PBF). Using the component setup described above, the system achieves a 50 kHz sampling rate to record process data such as single-channel and quotient-channel pyrometer temperature readings, controller outputs, and actual emitted laser power—all mapped to precise spatial positions.

This process data is seamlessly integrated with the Autodesk Machine Control Framework and stored in a proper database. The stored data can be extracted at any time to generate detailed heatmaps and plots, offering enhanced visualization and actionable process insights.

The resulting temperature control system effectively mitigates heat accumulation during layer exposure and stabilizes process temperatures across individual exposure vectors. Control plots generated from the system demonstrate its precision and reliability. The amount of detail and process insight is really remarkable.

Bremer Institute für Angewandte Strahltechnik (BIAS)

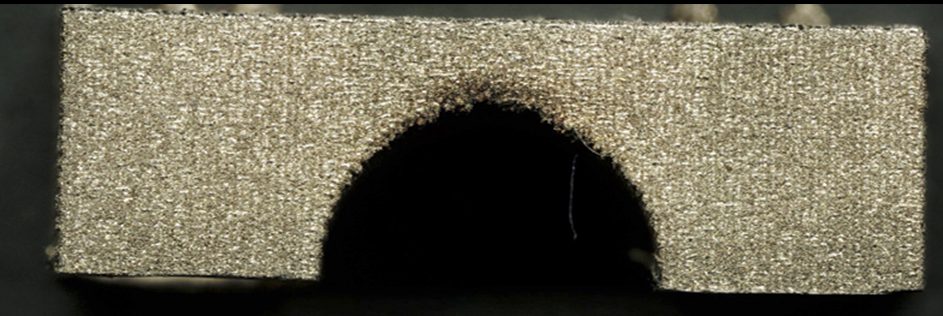

The BIAS in Bremen is one of Germany’s leading laser research institutions. Unlike real-time process adjustment, BIAS researchers have explored a discretized approach, modulating laser power based on data from the previously recorded layer.

In this method, the scan field is divided into thousands of small PID control elements, each independently adjusting the laser power for its specific region. This stepped approach effectively mitigates larger heat buildups, ensuring more consistent thermal management.

Preliminary results from test prints indicate promising reductions in keyholes and porosity. Thus demonstrating the potential of this technique to enhance part quality.

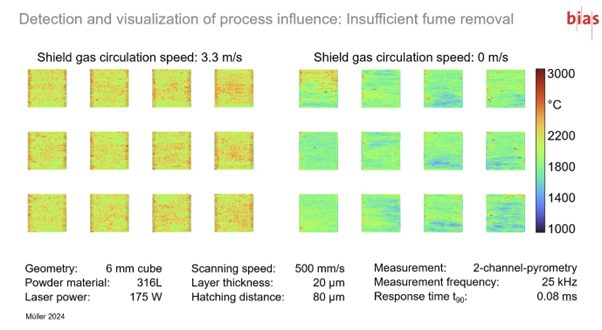

Even more intriguing are the adjacent measurements conducted as part of this project. Despite the high movement speeds of the scanner optics, the monitoring setup successfully detected gas flow disturbances and other process defects originating from the mechanical system. These findings highlight the system’s capability to capture critical process anomalies beyond thermal control.

Commercial impact

Melt Pool Monitoring has been a subject of academic research for many years. What sets SCANLAB’s approach apart is its ability – as market leader in this industry – to take these foundational research concepts and integrate them into one of their core commercial products. By adhering to industrial-grade development practices and delivering at an attractive price point, SCANLAB is helping to set new standards for the industry and bring greater maturity to additive manufacturing processes.

The Additive Manufacturing Team at Autodesk is proud to support SCANLAB in utilizing Autodesk Fusion as an integrated platform, enabling the delivery of end-to-end value to their customers.

FormNext 2024

If you’re attending FormNext 2024 in Frankfurt, Germany, visit us for discussions and detailed information

- Autodesk Booth, Hall 11.0 B51

- SCANLAB Booth, Hall 12.0 D42

- Sensortherm Booth Hall 12.0 C61