Elevate your design and manufacturing processes with Autodesk Fusion

Autodesk Fusion simplifies assembly design with flexible top-down and bottom-up methods, offering seamless workflows and dynamic adaptability. Its innovative tools, like Edit in Place and version control, enhance efficiency and collaboration.

When creating assemblies in Fusion, understanding the two primary approaches—top-down and bottom-up—is key to efficient design. This guide outlines these methods and how Fusion supports them.

Top-down assembly design

The top-down approach focuses on designing all parts within a single assembly context. In Fusion, this means working in one file where all components are created and saved internally.

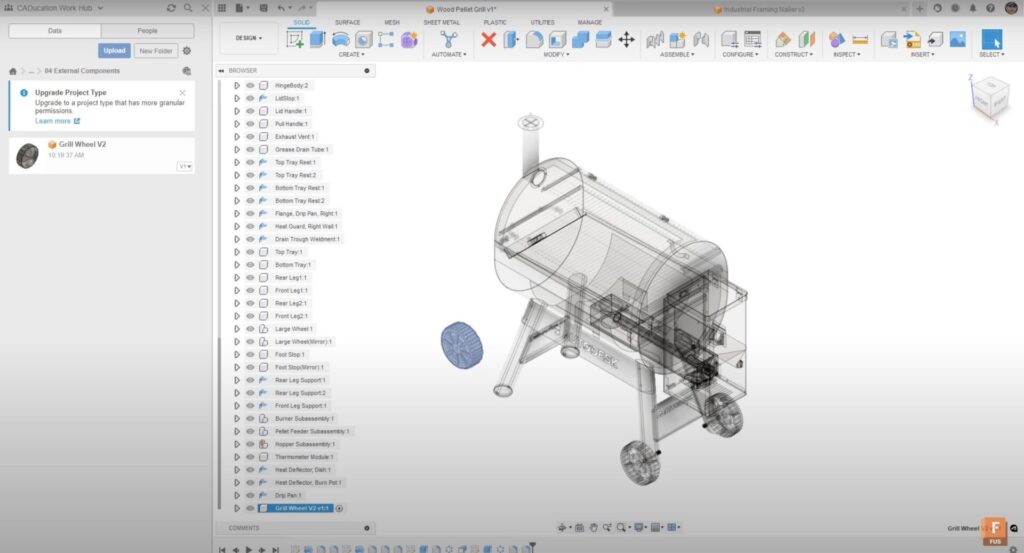

For example, a grille designed using this approach would contain all its components directly within the main design file. Fusion’s single design type eliminates the distinction between parts and assemblies, letting you decide whether to create components or bodies within the same file.

Benefits:

- All features, mechanical motion, and references are in one place.

- Easy cross-referencing between components during design.

Bottom-up assembly design

The bottom-up approach involves designing each part in its own file and bringing them together in an assembly. Fusion identifies externally linked components with a chain link icon in the browser, signifying their external status.

Features:

- Linked Components: You can open and edit these parts independently or break the link to internalize them.

- Version Control: Each save is logged, and milestones are flagged for significant progress. For example, a design might have hundreds of saved versions, allowing you to revisit earlier iterations.

Edit in place and assembly context

Fusion also allows external components to be edited within an assembly using Edit in Place. A pencil icon indicates when this feature is active.

When editing, assembly context is created, allowing you to reference geometry from other parts. These references are stored in the context of the main design, identified by a forward arrow icon, representing a derive.

Example:

If a casting in the assembly requires references from another component, you can project its geometry into your sketch. The assembly context maintains these connections for updates.

Flexibility in Fusion

Fusion enables seamless switching between top-down and bottom-up approaches. You can mix methods, creating some components internally while linking others externally. This flexibility allows designers to adapt their workflows as needed.

For instance, in a top-down design like the grille, you can still add new external components later, blending both approaches effortlessly.

Fusion supports both top-down and bottom-up assembly designs, offering tools like linked components, version control, and Edit in Place for a smooth workflow. Its flexibility allows you to choose or combine methods based on your project’s needs, ensuring efficient and adaptable designs.