& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

Up in Alberta, Canada, motorcycle designer Dale Yamada and machinist Phil Butterworth are taking aftermarket parts for Harley-Davidsons to a new level. After they noticed that “there’s nothing cool on the market,” Butterworth says, their MJK Performance machine shop began making “cool, weird, technical, mechanical-looking parts” for Harley enthusiasts.

Yamada, who’s earned a reputation as a top-flight engine builder, had already owned a custom motorcycle shop for several years when he met Butterworth. Yamada wanted a custom bracket fabricated for a bike he was working on, but he was frustrated that none of the machine shops he tried could make the part look like he wanted. Yamada appealed for help through his Instagram account, and Butterworth ended up making that part for him.

Butterworth had been designing oil-field machinery for a number of years. When Yamada asked him, “Do you want to buy a CNC with me?” he jumped at the chance to work with the designer on the side. They bought their first small mill the next week, and began making more parts for the custom bikes that Yamada was building.

Shortly, thereafter the two men joined forces. Along the way, Yamada set aside the custom motorcycle business in favor of designing aftermarket parts. As Butterworth explains, they are “trying to make very high-end, performance-oriented things . . . not just the kind of thing you bolt on to make it look nice.” Parts like theirs are more common on sport bikes, but much less familiar for Harley riders.

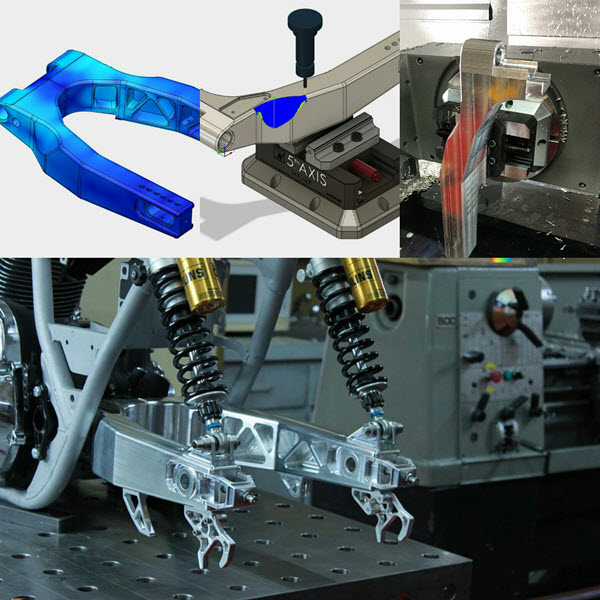

They started by making swingarms—the metal fork that connects the body of a motorcycle to the rear axle. Since then they’ve added handlebars, axles, suspension lifts, and wheels, and now they are developing their own brakes. “The swingarms are a big thing,” Butterworth says. “No one’s seen stuff like this.” The uniqueness of their products has boosted their appeal, and word has traveled fast among Harley fans.

Remarkably, MJK has kept growing with no advertising and no dealers. “Everything’s Instagram,” Butterworth explains. When they make a new part, they photograph it and put it on the company’s Instagram account, which now has 25,000 followers. “A couple of posts,” he adds, “and everything we’ve made is sold.”

They are building their reputation on scrupulous attention to detail. Butterworth gives the example of bolt-holes that they machine to tolerances much finer than needed. “No one will notice it, but we will,” he says. “We want to be known for perfection and quality.

When Butterworth lies in bed and has more ideas pop into his head, he gets back up and works on designs. This is made much easier because he and Yamada use Fusion 360 on their computers both at home and in the shop, so the designs can be shared instantly.

“It so easy, so user friendly,” Butterworth says, describing Fusion 360 as “hands-down” better than other CAD and CAM programs he’s used over the years. “The design side is so easy, and then to have the CAM side right there—and 5-axis.” The last part is especially important to him, given that 5-axis milling software alone can cost tens of thousands of dollars. “If we had to do this any other way,” he adds, “we just couldn’t afford it.”

The two partners iterate quickly through designs, and Butterworth says he often likes using the branch feature to make five or six designs to try out different concepts before weeding them down. He also relies heavily on the rendering features, which makes it easy for him to “see exactly what something will look like before it’s made.”

In the bigger picture, the software “definitely speeds up the process on our end” by saving them many hours across the steps of design, rendering, and machining. “I can have something from design stage to off the machine in one hour, if I’m working hard,” Butterworth says. “Having everything in one software is perfect.”

They’ll have to keep working that fast to keep up with their own ambitions. The partners expect to produce another 30 products in the next two or three months, a pace that Butterworth admits is “kind of crazy.” Their vision to “turn this whole industry upside-down” compels them to keep pushing boundaries.

As they continue to expand their capabilities (they’re getting a lathe to use alongside their 5-axis CNC mill), they also continue to expand their goals. Butterworth doesn’t hesitate when he says, “We’d like to make a fully CNC bike as soon as we can.” He explains that their ambitions are about much more than material success:

“We don’t want to collect paychecks. We want to do something fun that we can be proud of.”

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.