& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

Today I am very excited to introduce the Fusion 360 community to a new app from our friends at The Product Launch company: Composite Connectors. I am excited about this for a number of reasons beyond just the general awesomeness of the composite connectors themselves. First of all the founders are longtime friends of the Fusion 360 family including longtime forum superuser: Peter Doering, aka TrippyLighting. Next is what this represents, it is a vision of a connected product development process where designers are able to directly connect with supplier data, in real time, and seamlessly go from design on screen, to components in hand. With that, I’ll turn it over to the other founder, Pat Conarro, who will give an overview of exactly what they have been up to:

Composites are a popular choice for assemblies that need to be strong and lightweight. The problem for designers is that many structures using carbon fiber or Kevlar, require molds, layup tools, or post-process machining –which results in long lead times and expense.

CompositeConnectors.co is the solution you’ve been waiting for, and is NOW available on the Autodesk app store! This engineered construction system drops components right into your design, in multiple stocked sizes, giving you quick turnaround while improving weight to strength ratio.

How Does It Work?

This is no ordinary erector set system and plugin. After much thought, and our commitment to the long-term Fusion 360 roadmap, we built something every designer wants in their toolbox.

Do you ever get tired of going into your design, counting up parts, then heading back to the store to order and get things that you just downloaded? Real-time weights, costs and more inside of your CAD system should be natural and easy to use. We call it….drag, drop, and shop technology.

Want to get the best price available on the web? Fusion 360 will have it anytime you calculate price because our app connects Fusion 360 directly to our store. Download the Composite Connector App and start designing in a whole new way.

What Are Composite Connectors Different?

Now, onto the parts themselves. We have multiple print heads in our 3D printers so Composite Connectors are built using carbon fiber strands, bound together with a carbon fiber/nylon binder. Our printer farm consists of Mark Forged technology, that makes these great shapes.

Your drag and drop design world works better because we get you to checkout faster, so you can focus on designing and making, not purchasing Also, the Fusion 360 components are smart because they talk to our store as soon as you start designing.

Need to copy or modify a part? We count everything up in the menu when you’re ready to check out, so feel free to copy and paste all day.

How Do I Bond These Connection Points with Carbon Fiber Tube and Plate?

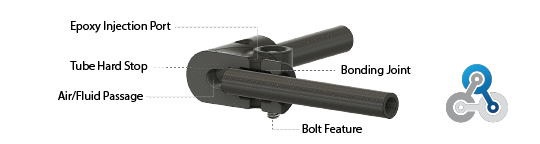

Every connection point has (2) fill holes, a hard stop, and a glue joint that amplifies the bond strength. When you cut open a Composite Connector, you will find a small glue joint that holds everything together. We have come up with a special epoxy glue system that ensures your bonds are at their highest strength when you finish the assembly process. Our static mixing tube couples up with each connection point glue portal.

Did we mention that these shapes are able to pass fluids and air at high temperatures? Need to run a wire to a sensor, or make a pneumatic mechanism move? We have built a plumbing system thru the inside. Many connectors also include bolt patterns so you can easily mount to the structure.

Are Our Epoxies Stronger Than Most?

In many cases, the 3K weave carbon fiber tube will fail before the connector joint bond. Because we developed an awesome epoxy with NanoTubes built into the resin side of the glue, our Carbon NanoTubes are microscopic carbon fiber structures that provide an interlocking structure that is very hard to break.

What Can I Build with Composite Connectors?

Well, that is up to you? We have a long list of DIY kits that are going up on the store over the next 12 months. That said, your imagination can make the following:

I Can’t Find What I Need on The Store?

Need something that is not in the store? We’ve got, you covered. Our MarkForged printers are here to make custom parts. Just hit the email button in the app and send us your part in a native Fusion 360 archive (.f3d) format. or you can find us at sales@overnightcomposites.com.

What Kind of Tolerances and Finishes Can I Expect?

While cosmetics are pretty awesome at .1mm resolution, we do have some flaws where supports are placed. Now tolerances are something to talk about.

Knowing that our build volume is 320mm x 132mm x 154mm, we have chosen to slow things down a bit to get you some tighter tolerances. Over a 300mm build length, we are seeing +/-.10mm. The other 2 axes are even tighter. Something that is half that build size, we are seeing +/-.8mm. Weight tolerances are +/-2% for connectors since we hand that information from our store. Tube weights are going to measure 1 meter lengths, so that calculation is off when you change the lengths.

The Fusion 360 API Integration with Shopify?

We had the pleasure of working with Patrick Rainsberry from the AutoDesk Fusion 360 Business Development Team in this integration.

Here are some great reference points for your next BIG E-Commerce integration with Fusion 360 and Shopify.

Give us a shout anytime if you need help with your Fusion 360 to Shopify workflow or need some code examples.

e: integrations@theproductlaunchcompany.com

ph: 719.684.3155

Product Launch Company © 2017 – Colorado USA

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.