Learn how to use electronic design automation and modular design blocks to streamline the development process.

Speed and efficiency are crucial for successful circuit design in the ever-evolving field of electronics engineering. Engineers have embraced the power of design automation and modular design blocks to streamline the product development process. Ultimately, engineers can design circuits faster and easier by leveraging these approaches, increasing productivity and innovation.

Let’s explore the utilization of design automation and modular design blocks, providing real-world examples to illustrate their effectiveness in circuit design workflows.

Electronic Design Automation: Empowering Efficiency and Consistency

Electronic design automation refers to using software tools and methodologies to automate various stages of the circuit design process. It minimizes manual effort, reduces errors, and ensures consistency across designs. Here are some examples of electronic design automation in action:

Schematic Capture Automation

Schematic capture tools like EDA (Electronic Design Automation) software enable engineers to create circuit schematics quickly. These tools provide libraries of pre-designed components, allowing engineers to drag and drop the required modules into their designs. With automated wire connections and component annotation, schematic capture automation accelerates the initial design phase.

PCB Layout Automation

Automated PCB layout tools enable engineers to efficiently translate their schematics into physical circuit boards. These tools offer features like automatic component placement, routing algorithms, and design rule checks (DRC) to ensure proper board layout. By automating these tasks, engineers save time and reduce the likelihood of errors associated with manual placement and routing.

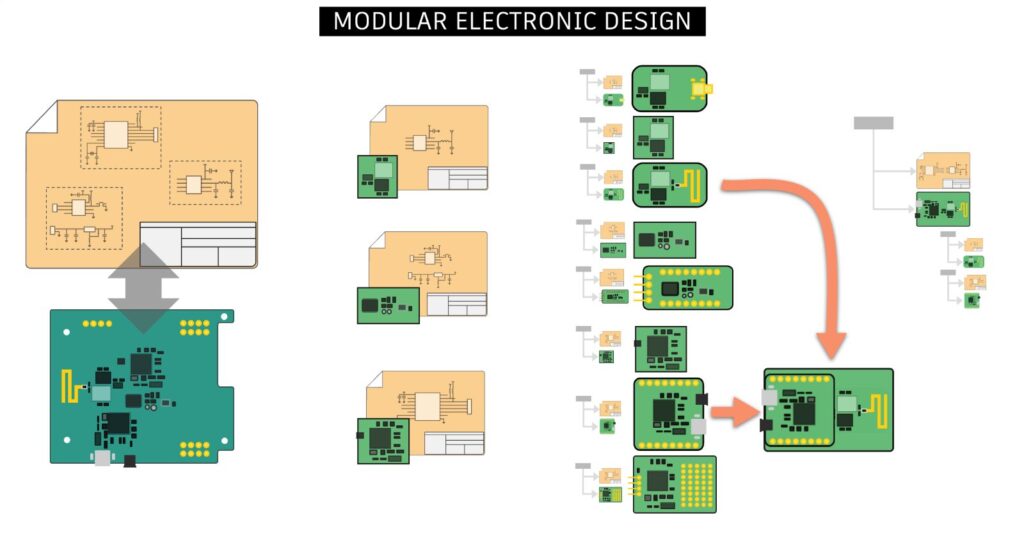

Modular Design Blocks: Building Circuits Piece by Piece

Modular design blocks involve creating reusable, self-contained circuit modules that easily integrate into larger designs. This approach promotes efficiency, reusability, and collaboration among design teams. Let’s explore some practical examples of using modular design blocks:

Power Management Module

In many electronic systems, power management is a critical aspect. Designing a power management module as a separate block allows engineers to focus on optimizing power conversion, voltage regulation, and efficiency. Once developed and tested, this module can be reused across multiple designs, eliminating redundant design efforts.

Communication Modules (e.g., Wi-Fi, Bluetooth)

Wireless communication modules like Wi-Fi and Bluetooth are commonly seen in various electronic devices. Designing these modules as independent blocks simplifies integration and allow engineers to concentrate on signal integrity, interference mitigation, and communication protocols. These modules incorporate different circuit designs, enabling the rapid development of wireless-enabled devices.

Design Block Workflow: Streamlining the Design Process

A design block workflow involves a systematic approach to circuit design by breaking down the overall system into smaller, manageable blocks. This workflow ensures a structured development process, facilitates parallel design activities, and enhances design reuse. Consider the following workflow example:

Microcontroller-Based System

For a microcontroller-based system, the design block workflow may involve separate blocks for power management, a microcontroller unit (MCU), a communication interface, and peripheral modules. Each block can be designed independently, allowing teams to work concurrently on their respective areas. Once completed, the blocks are integrated and tested, ensuring a faster and more efficient development cycle.

To implement modular design in circuit board development, it’s important to keep several key considerations in mind:

- Clearly Define Module Interfaces: Defining the interfaces between different modules is crucial to ensure seamless integration. This includes specifying electrical, mechanical, and communication interfaces to establish smooth interconnections.

- Standardization: Establishing standardization guidelines for module design, such as layout, pin assignments, and power requirements, ensures compatibility and simplifies future integration.

- Thorough Testing: Each module should undergo rigorous testing to verify its functionality and performance before integration. This reduces the risk of errors and compatibility issues during the final assembly.

- Documentation: Maintaining comprehensive documentation for each module, including schematics, specifications, and testing procedures, is essential for efficient integration and future reference.

Electronic Design Automation and Modular Design

Electronic design automation and modular design blocks offer significant advantages in circuit design workflows. Engineers can save time, ensure consistency, and enhance collaboration by automating design processes and utilizing reusable modular blocks.

The real-world examples demonstrate the effectiveness of these approaches in accelerating circuit design. Embracing design automation and modular design blocks empowers engineers to overcome design challenges, explore new possibilities, and drive innovation in electronics engineering.

Get started with electronic design automation and modular design

Download a free 30-day trial of Autodesk Fusion 360 today.