Both additive and subtractive manufacturing have revolutionized the way products, parts, and prototypes are made and continue to advance rapidly. Ever wonder what the difference is between additive manufacturing vs. subtractive manufacturing? This article has you covered.

Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3D printing. Subtractive manufacturing, as the name suggests, is the opposite.

Rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away. It can be carried out manually or, more commonly, by a process known as Computer Numerical Control (CNC) machining.

This article provides a detailed overview of the main differences between the two methods. It also dives into the pros, cons, and main applications of each.

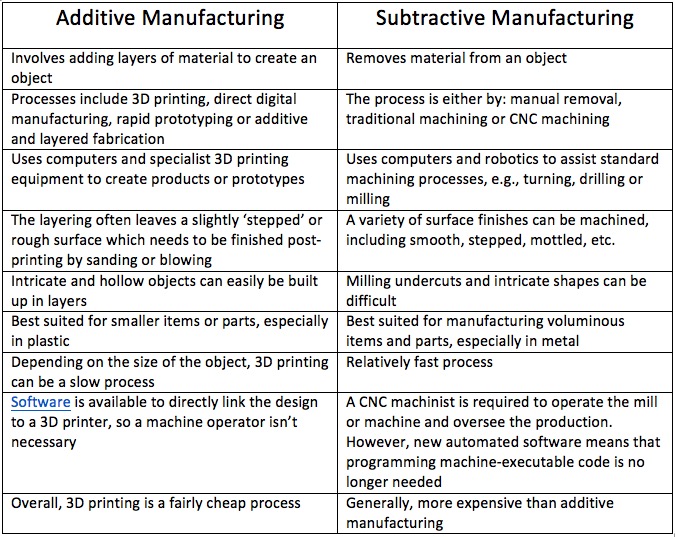

Additive vs. subtractive manufacturing comparisons

There are several fundamental differences between additive and subtractive manufacturing in both the processes and results. The below table directly compares both techniques:

Applications of additive and subtractive manufacturing

As well as the differences listed above, there are some similarities between the two methods. For example, they are both widely used to fabricate prototypes.

Both additive and subtractive manufacturing expedite the prototyping process. The main consideration is the volume and type of material and the effect this will have on the speed of fabrication. A large object with a high volume, a large metal cog, for example, lends itself more to subtractive manufacturing. A small plastic part, such as a bracket, might be more suited to additive manufacturing.

Producing finished products

CNC machining is still the favored method for most manufacturers looking to fabricate finished products. The main reasons are the speed of the process, the choice of surface finishes, and the fact it is better suited to high-volume production.

Additive manufacturing is normally reserved for highly specialist parts that require only a small production run, such as small aerospace engine parts. Also, highly complex and intricate items, especially those that require a hollow interior (to save weight or material), are usually 3D printed.

Hybrid additive and subtractive manufacturing

Hybrid mnaufacturing systems combine the versatility of additive manufacturing with some of the advantages of subtractive methods. Specialist machines can perform both operations, meaning that complex parts can be made more easily. Hybrid manufacturing is particularly good for repairing worn or broken parts, as the material can be added in layers, and then finished with milling tools.

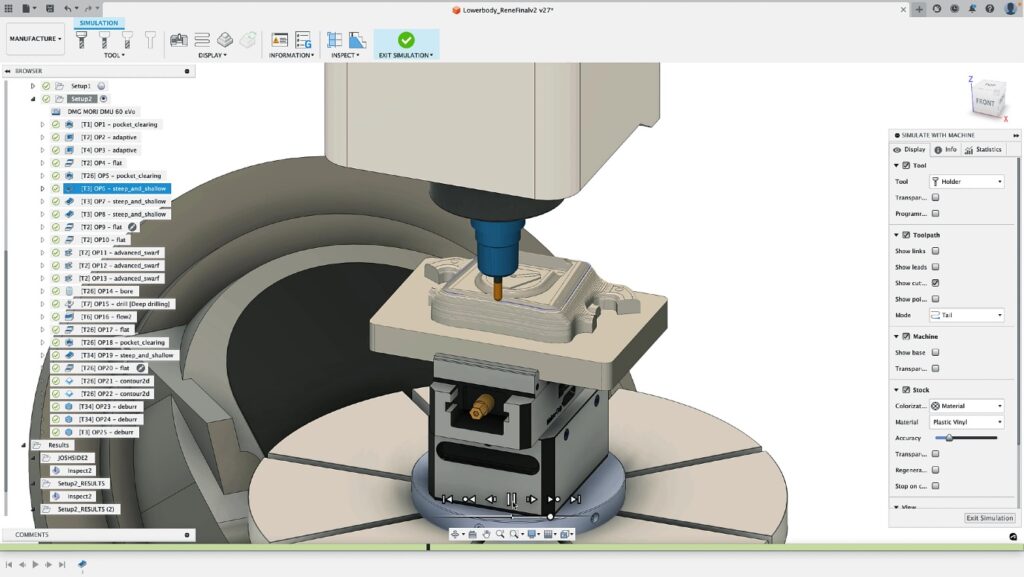

Autodesk Fusion CAM for CNC machining

Autodesk Fusion and the Fusion Manufacturing Extension offer advanced CAM capabilities, including 4- and 5-axis simultaneous machining, sheet-based nesting and fabrication, and metals-based additive manufacturing. It’s an all-in-one solution that enables teams to leverage all that additive manufacturing and subtractive manufacturing have to offer.