Shannon McGarry

Discover how integrated Product Data Management (PDM) and Product Lifecycle Management (PLM) systems help leaders reduce risk, accelerate development, improve quality, and drive operational efficiency across the full product lifecycle. With compressed timelines, globalized supply chains, and rising quality expectations, manufacturers face constant pressure to deliver smarter, faster, and with greater resilience. Yet many organizations…

Data management

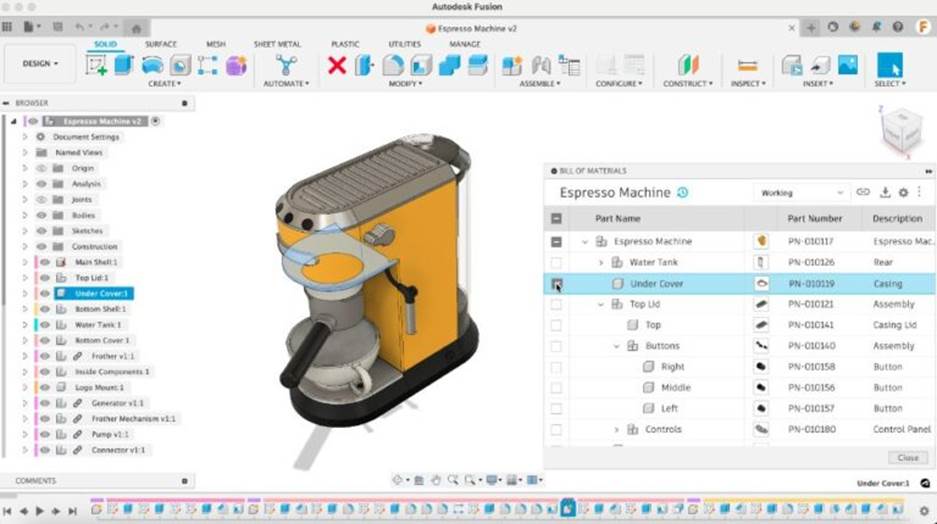

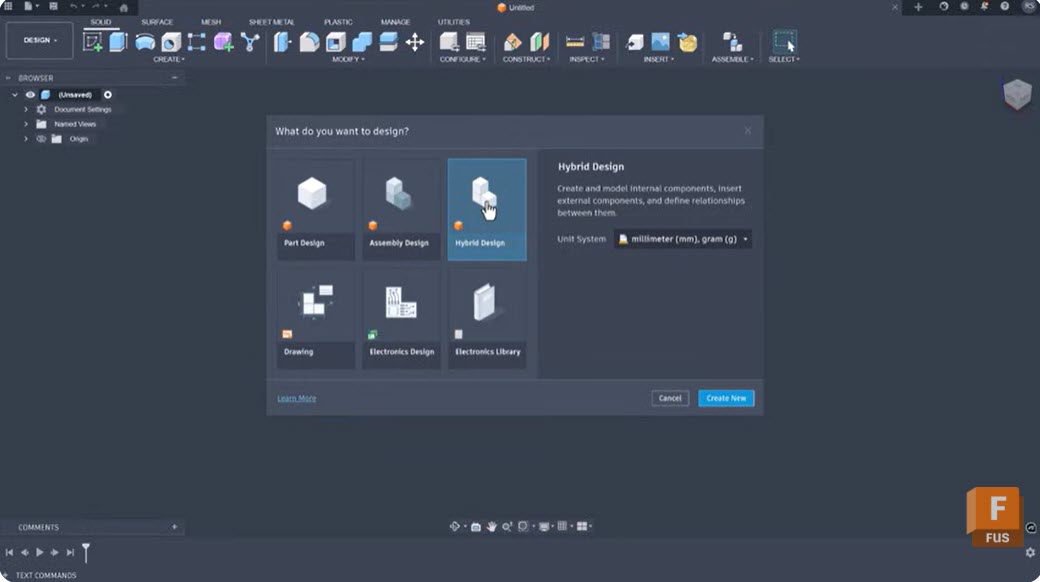

Explore how connected product development improves key engineering metrics of time-to-market, first-pass yield, and cost of poor quality. Learn how integrating ECAD, MCAD, and PLM reduces latency and errors and how Autodesk Fusion can help. Product development teams constantly face pressure to deliver complex designs faster and with fewer errors. One means of alleviating these…

Product Design & Engineering

Discover how Autodesk Fusion for Manufacturing can help your job shop overcome programming bottlenecks, reduce downtime, and boost profitability with integrated CAD/CAM workflows. The reality for job shops today If you run a machine shop, you know the daily pressure you face. Customers want shorter lead times, tighter tolerances, and competitive pricing. Meanwhile, skilled labor…

Fusion

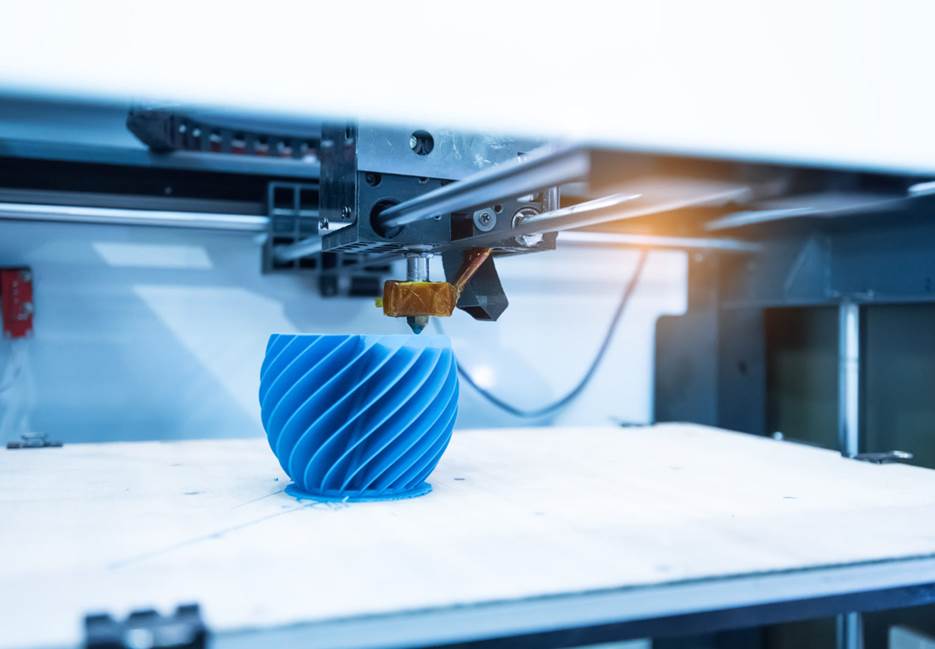

Additive manufacturing delivers value through prototyping, functional testing, customization, lightweighting, and digital inventory. These applications need fast iteration and strong links between design and production. Fusion supports this need by integrating additive preparation with CAD and engineering workflows so that teams improve consistency, speed, and manufacturability. Additive manufacturing has moved well beyond its early application…

Product Design & Engineering

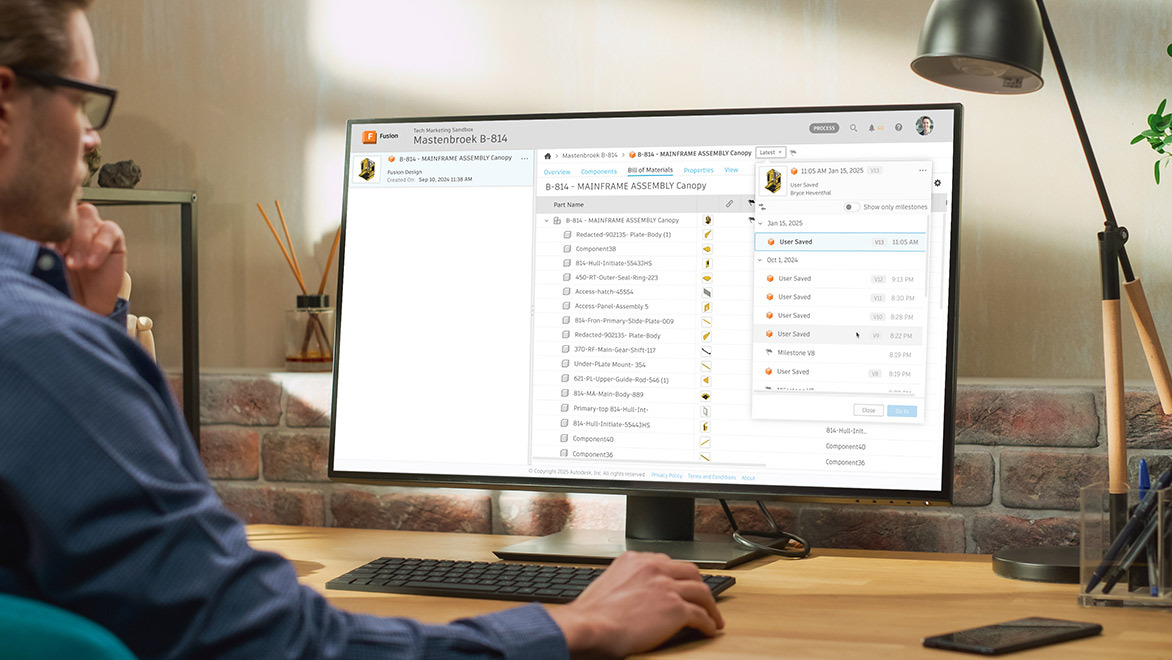

Manufacturers aren’t slowed by production—they’re held back by siloed data. Fusion for Design unifies CAD, PDM, and PLM to eliminate friction and accelerate innovation. Industry studies report that 68% of organizations cite data silos as their top concern. Teams juggle with disconnected CAD files, project notes, supplier updates, BOM revisions, and compliance documentation spread across inboxes, shared…

Data management

Find clear answers to the top 20 Autodesk Fusion technical questions, including modeling, assemblies, simulation, and CAM issues. Get quick fixes and links to deeper guides. 1. Why won’t my sketch fully constrain in Fusion? This happens when geometric or dimensional constraints are missing. Small gaps or misaligned endpoints often cause under‑constrained sketches. Use Show…

Tutorials

Intent‑driven design in Fusion removes workflow friction by helping teams start with the right modeling approach and adapt seamlessly as projects evolve. Design projects often stall before they start – not because of complexity, but because teams are forced into workflows that don’t match how they actually build. When tools lock designers into rigid modeling…

Product Design & Engineering

Achieve process improvement in manufacturing with Autodesk Fusion—streamline workflows, cut waste, and accelerate production in one connected platform. Manufacturing success today depends on one critical factor: operational efficiency. Companies that fail to optimize processes face rising costs, missed deadlines, and shrinking margins. In contrast, organizations that embrace systematic process improvement achieve productivity gains of 25–40%,…

Manufacturing

Cut errors, speed launches, and improve collaboration with Autodesk Fusion’s integrated PDM—one platform for design, manufacturing, and data control. Data is the backbone of every product decision. Yet, many organizations still rely on manual processes and fragmented systems to manage product data – costing them time, money, and market share. Studies show businesses lose up…

Data management

Autodesk Fusion now delivers integrated PLM in the same environment —connecting CAD, CAM, data, BOMs, and change management to reduce errors, accelerate releases, and improve product quality. A major milestone has arrived for product developers, engineers, and manufacturers: Autodesk Fusion now offers integrated product lifecycle management (PLM) in the same environment where teams design, engineer,…

Data management

Discover how closed-loop quality management connects non-conformance, CAPA, FMEA, and supplier actions into one system. Learn how Autodesk Fusion Manage helps manufacturers boost product quality, accelerate issue resolution, and ensure compliance and optimize designs for continuous improvement. Manufacturers constantly struggle with disconnected quality systems, delayed information flow, slow reaction to non-conformance, and siloed corrective action…

Data management

Discover Carter Bilawchuk’s Fusion journey building Euler Bikes — a self‑taught 16‑year‑old maker blending design, performance, and creativity into his most ambitious project yet. Welcome to our next Fusion Community Spotlight series where we celebrate the makers, builders, and dreamers using Autodesk Fusion to bring their ideas to life. These are the real stories of…

Customer Spotlight