Elevate your design and manufacturing processes with Autodesk Fusion

At Autodesk we always celebrate when we see great innovation in manufacturing. We’re especially proud when our extended family leads the charge. Last week three of our former interns (Nathan Fuller, Andy Baldwin, and Eric Thomas) placed 2nd in the NASA 3D Printed Habitat Competition! The competition is a multi-phase challenge whose purpose is to further technology to create sustainable housing solutions on planets like Mars, and here on Earth. Naturally, Martian settlements will need to be made from as little Earthly material as possible. (Clearly, it isn’t feasible to just chuck a bunch of 2×4’s from Home Depot into the back of the space shuttle.) Everything counts. Everything must have purpose and the ability to be repurposed. Lots of stuff going to Mars will be plastic and it is super important that even things like plastic packaging find a way to be recycled after settlers land on Mars. Hence this competition.

Essentially, teams are competing to see who can build the best giant 3D printer capable of extruding plastic mixed with Martian cinder to create robust structural components. Martian cinder is similar to the silicon sand and cinder we have on Earth. While the materials are familiar, the technology and methodology required to blend the two into a robust and repeatable additive manufacturing process is far from straightforward. Anyone who’s ever 3D printed anything other than straight PLA or ABS plastic will attest that putting anything grainy into a 3D printer ends up being a heaping, gunky, cloggy, abrasive mess. Further research is indeed required.

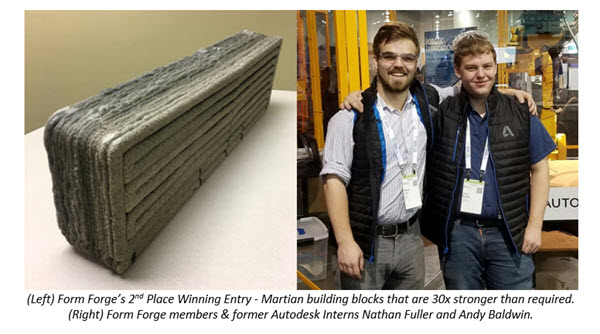

And, so here we are! After a long winter and spring of hard work, Form Forge literally “crushed it.” Their sample (shown below) withstood over 30,000 lbf (13,600 kg) in bending! (For context, the competition only required 1000 lbf.) With big results came big rewards. Their 2nd place finish netted them over $67,000 USD.

The material they competed with feels both familiar and foreign. It’s 70% Silica (“sand”) and 30% High Density Polyethylene (HDPE) (Plastic water pipes, bottle caps, lawn furniture). It’s heavy. It has the weight of traditional clay bricks. Yet, it doesn’t feel like a brick. It feels unmistakably plastic. It doesn’t flake or have a chalky consistency. It sticks together nicely.

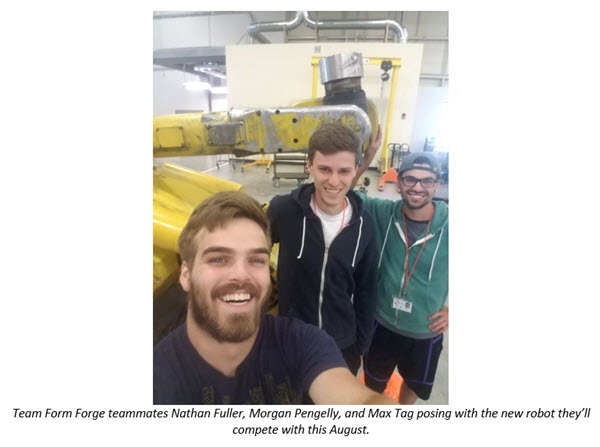

Next up, the team is preparing to compete in the 3rd stage of the 3DP Challenge this August. While the first two legs consisted of providing smaller samples that could be created from prints made on a moving print bed (which is basically how most consumer-grade 3D printers work today), this next phase will be at a whole new scale and will require a much larger test sample that will surpass the dimensions of what Form Forge feels can be done with conventional moving print beds. For the next phase they’re mounting their big extruder on a big 6 axis robot. A rendering of what they are planning is shown below:

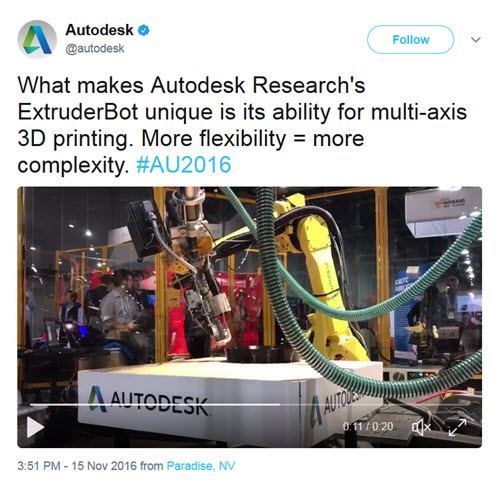

While both the shape and size of the required sample is formidable, this team knows a thing or two about mounting extruders to robots. Last summer, that’s exactly what Nathan and Andy did working in our Pier 9 Robotics lab with our Advanced Research team on “Extruderbot.” Check out what they unveiled at last year’s Autodesk University:

Form Forge is a hardware and software startup based in Corvallis, Oregon. Their vision is to reshape manufacturing by “making todays designs into tomorrow’s reality.” Their core technology which they call their “Free Form Additive Technology” consists of a software based system to drive industrial robotic arms and utilize their proprietary automotive-scale 3D print extruder. 3D printing methods use 2D layers that can fail under gravity, leaving many of our best ideas stuck in the cloud.

Like many stereotypical startups Form Forge’s first “office” was their house. When they started working on the extruder they had the choice of either doing their laundry or working on their extruder because their one 3-phase power outlet could only power one at a time:

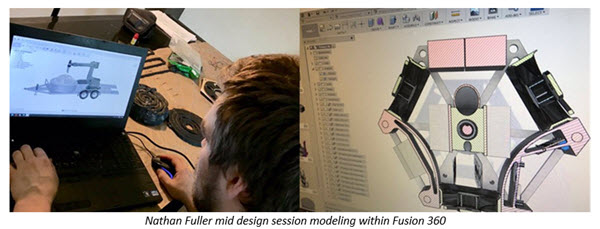

Yup, they love their Fusion 360. They’re heavy users of Fusion’s modeling, simulation, and visualization tools:

We’ll be following and rooting for them as they head down the final stretch. We’re extremely proud of Form Forge (and the rest of the teams for that matter) for being at the forefront of these large macroscopic trends in manufacturing that will fundamentally and rapidly change the way products are designed, made and used. See you in August!